New Product Launch: Fanuc 31i+C+Y Mill-Turn Simulator - Leading the New Era of CNC Training

today

2024-05-30

local_offer

CNC Machining Knowledge

visibility

1771

RenAn Information Technology introduces the latest Fanuc 31i+C+Y mill-turn simulator, a cutting-edge product that integrates the latest simulation technology. This innovative device allows users to simulate both turning and milling operations on a single machine, greatly enhancing the efficiency of learning and training.

Why Choose RenAn’s Fanuc 31i+C+Y Mill-Turn Simulator?

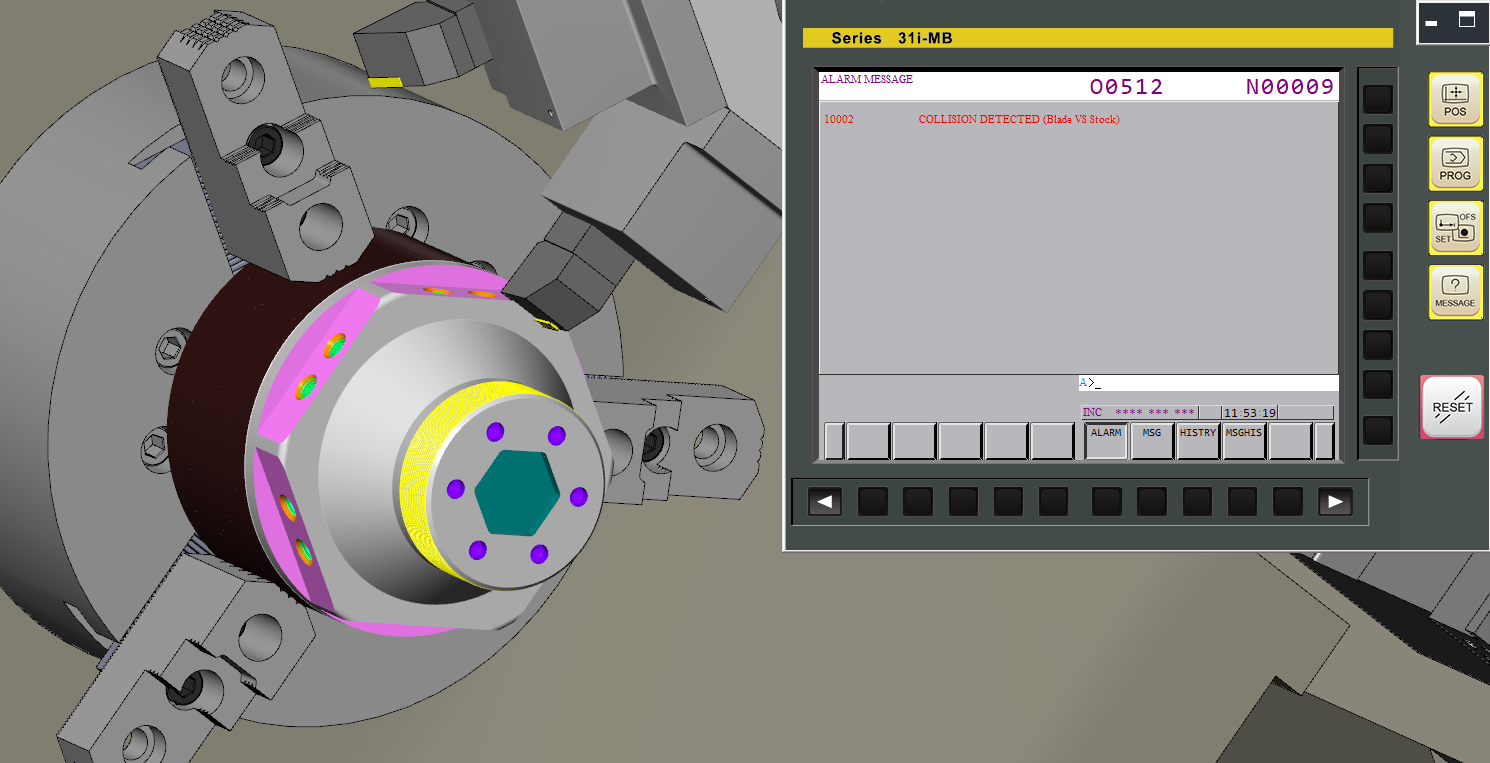

This simulator boasts advanced features such as precise tool length calibration and a alarm function, which immediately notifies users of any operational errors. This not only ensures operational safety but also allows trainees to practice repeatedly in a safe environment until they are fully proficient, laying a solid foundation for becoming professional machinists and operators. The machining program simulation includes polar coordinate commands G112, cylindrical commands G107, G18 plane ZX-axis turning, G17 XY-plane milling, axial drilling G83 tapping G84 boring G85, G19 YZ-plane milling, radial drilling G87 tapping G88 boring G89.

Realistic Operation Experience, Comprehensive Skill Development

The simulator is equipped with an industrial-grade operation panel, including mode selection knobs, rate adjustment knobs, a physical handwheel, and an emergency stop button, providing trainees with a realistic operational feel and real-world experience. Using RenAn CNC training software and equipment, the entire CNC machine can simulate 3D turning and milling operations. The program automatically executes based on NC code interpretation, combining machine and tool display, making it ideal for beginners to understand the workings of a CNC machine. Trainees can directly edit programs on the simulated CNC controller, set OFFSET tool length compensation, CNC coordinate systems, and CNC program automatic operations, among other settings, allowing them to solidify their CNC operational foundation through repetitive practice.

Smart Alarm Function for Precise Learning

The simulator’s built-in smart alarm function enables trainees to clearly understand specific issues during operation errors, such as overtravel or tool-to-workpiece collisions, helping them to promptly identify and correct mistakes, thereby improving learning efficiency and operational skills.

Digital Instant Assessment System

The digital assessment system can conduct tests and provide automatic scoring in real-time, allowing trainees to immediately understand their learning progress and practical skills level. Instructors do not need to wait until trainees use the actual machine to identify any deficiencies that might lead to collisions.

About RenAn Information Technology

Since establishment in 1987, RenAn Information Technology has been dedicated to optimizing the CNC learning experience for students by providing high-quality CNC teaching software and training equipment. We are the global partner of choice for CNC training.

文章區塊