Case Study - Feng Chia University (Taiwan)

today

2024-07-15

local_offer

Case Study

visibility

1078

Experience Sharing: Teaching Methods and Benefits of Using CNC Simulation Software

Professor Wu-Chang Guo, Department of Mechanical and Computer-Aided Engineering, Feng Chia University, Taiwan.

When teaching CNC milling programming, the formatting function provided by RenAn software aids in readability and debugging. The comparison function within the environment facilitates easy identification of differences across multiple accumulated processing programs. The integrated environment, which supports the inclusion of annotations, images, and video files, is quite suitable for collecting the accumulated machining experiences of organizations over the years.

The intuitive icon and setup method for setting the machining material G54 is helpful for learning. The tool database offers a wide selection of tool types, making the simulated product close to the expected goal. The built-in functions for editing, modifying, and saving tools also cater to different machining accessory needs. The operation of the simulation screen is simple and intuitive, clearly indicating machining errors and defects, which helps predict the finished workpiece. Overall, it is a great teaching assistant for educators.

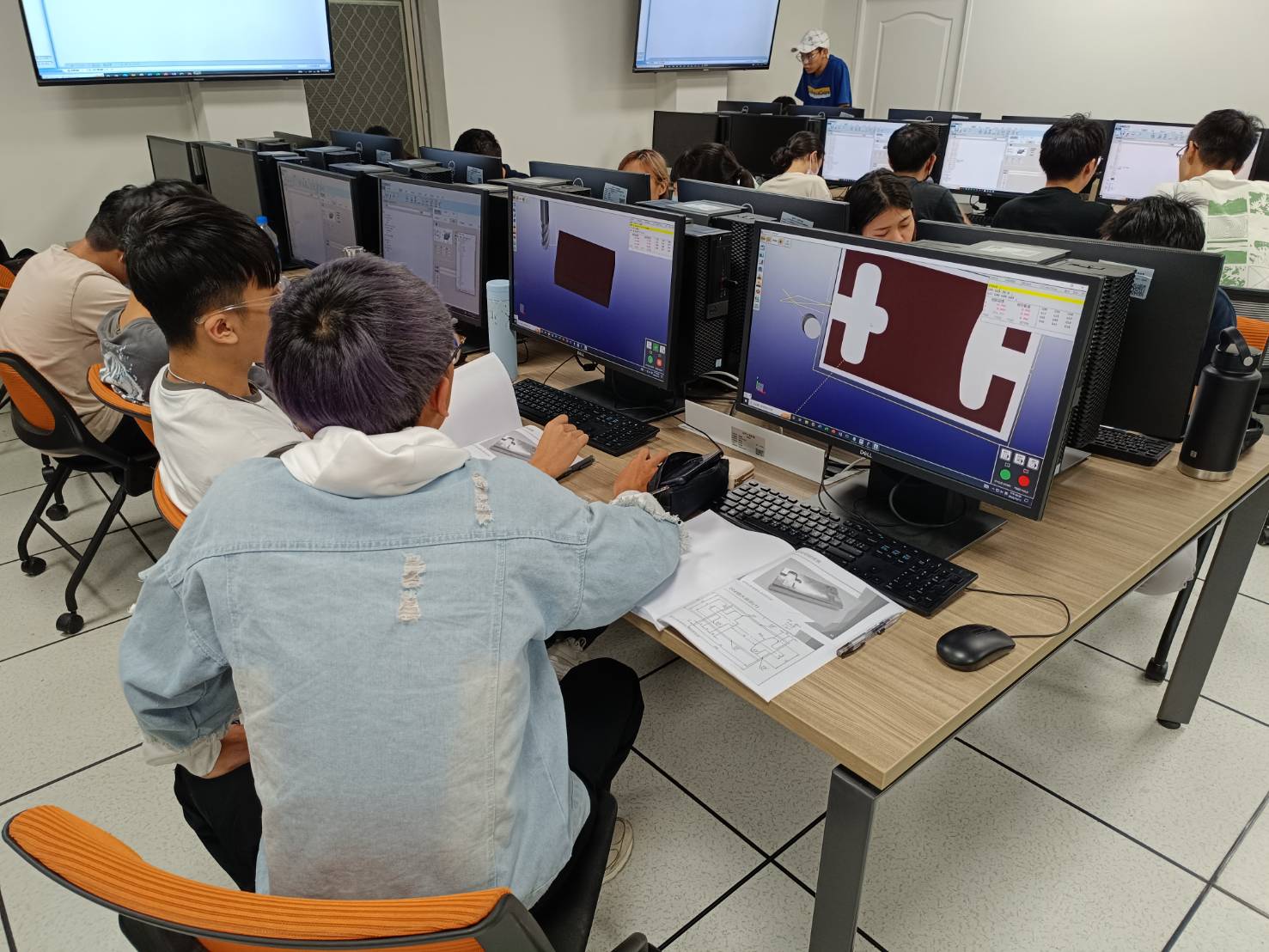

(Photo provided by Professor Guo)

Student Qiu's Sharing on Course Participation:

During the learning process with RenAn CNC software, I gained a lot and developed a deeper understanding of CNC machining technology.

Feedback and Experience:

RenAn CNC software has a clear and simple user interface, comprehensive functions, and is very convenient to use. The operational teaching of the software is very detailed, progressing from basic to advanced steps, allowing me to quickly grasp the operation methods of the software. During the learning process, I encountered some difficulties, but under the patient guidance of the teacher, I was able to resolve them smoothly. The teacher's explanations were very lively and easy to understand, helping me grasp the core concepts of CNC machining technology well.

Learned Content:

In the learning process with RenAn CNC software, I learned the following:

• Basic knowledge of CNC machining, including machining principles, machining programs, and machining machines.

• Operational methods of CNC software, including drawing, programming, and simulation.

• Common applications of CNC machining, including milling, turning, and drilling.

Through learning, I gained a comprehensive understanding of CNC machining technology, could proficiently operate RenAn CNC software, and apply it to actual CNC machining work.

Specific Learning Content:

In drawing, I learned how to use RenAn CNC software to draw 2D graphics and 3D models. In programming, I learned how to use RenAn CNC software to write G codes and M codes. In simulation, I learned how to use RenAn CNC software for machining simulation. During the learning process, I also learned some common applications of CNC machining, including milling, turning, and drilling. These applications are the most common machining methods in CNC machining. Through learning, I can proficiently use RenAn CNC software for these machining operations.

Conclusion:

RenAn CNC software is an excellent CNC software that helps students quickly master CNC machining technology. In the learning process with RenAn CNC software, I gained a lot and developed a deeper understanding of CNC machining technology. I believe these knowledge and skills will play an important role in my CNC machining studies.

(Photo provided by Professor Guo)

Student Zhang's Sharing:

Feedback and Experience:

The user interface of RenAn CNC simulation software is very simple and clear. Through this software, I have a better understanding of the process and principles of computer numerical control machining. The simulation software of RenAn has many user-friendly designs, such as the ability to execute step-by-step during the simulation of tool paths, which is very helpful for beginners to find errors in the program.

Learned Content:

Through RenAn software, I can simulate the path of each program, thereby finding the best and most efficient cutting path. Additionally, I believe RenAn software greatly improved my ability to write CNC programs, as the assistance from RenAn software at the beginning of the semester helped me quickly understand the logic of program writing.

(Photo provided by Professor Guo)

文章區塊