RenAn 2024 version What's New! Fanuc system

today

2024-08-27

local_offer

News

visibility

1279

We are pleased to introduce the latest 2024 version of our software, which includes several new features and enhancements based on customer feedback.

These improvements not only enhance the user experience but also further strengthen the stability and performance of our product.

- - - Feature Description - - -

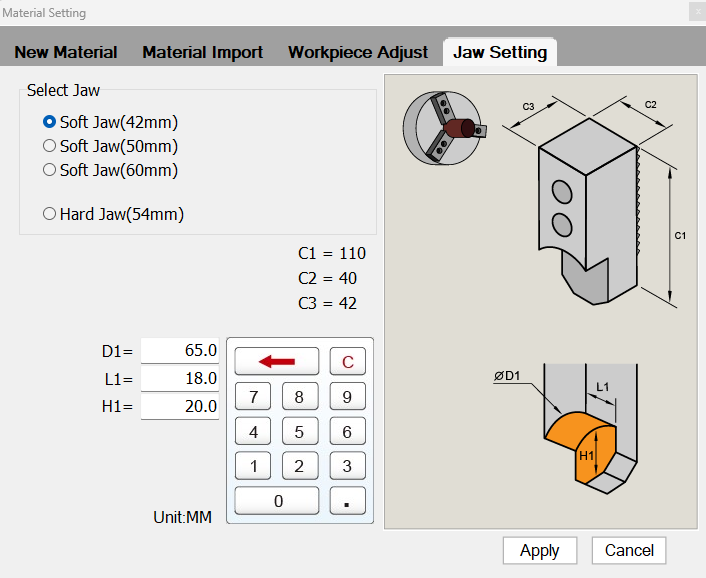

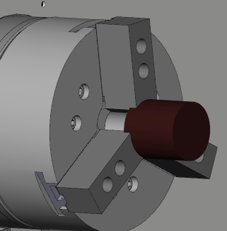

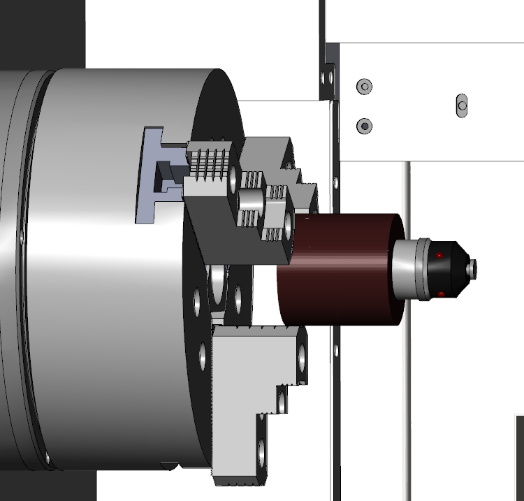

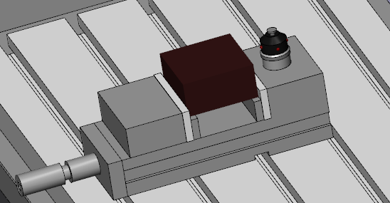

1. Added jaw setting in material setting

Example: Changing jaw

- Toolbar [Material Setting] > [Jaw Setting]

- Select [Soft Jaw (Height 42mm)]

- Click [OK] to apply

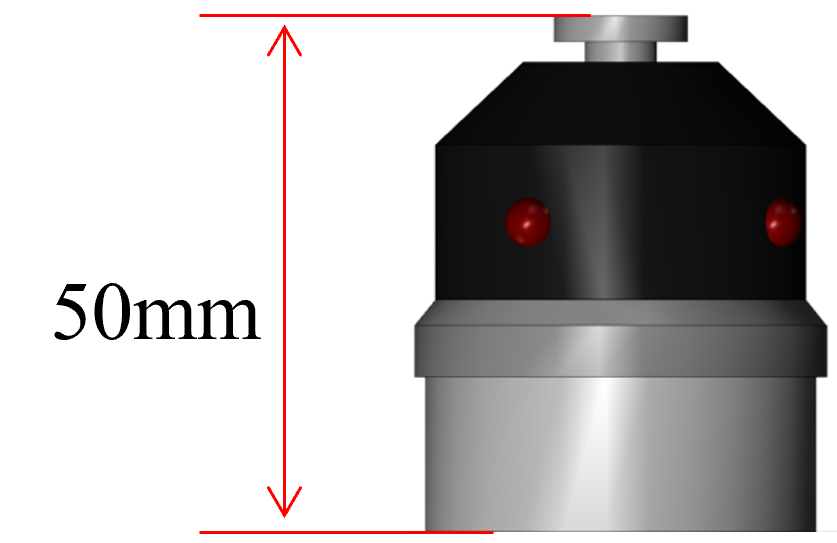

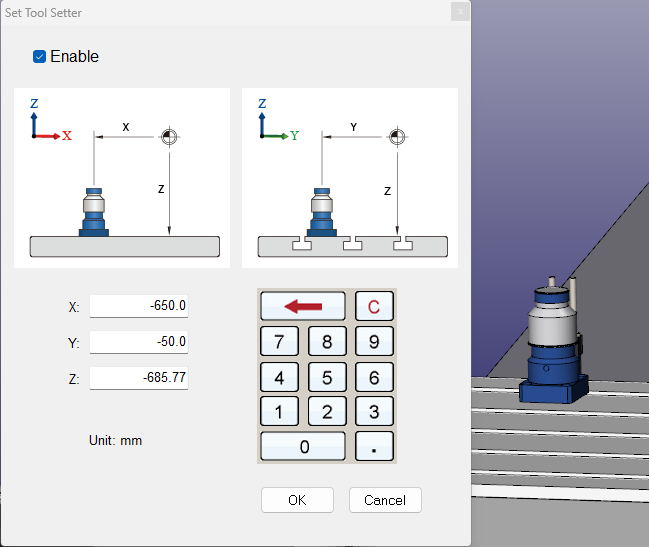

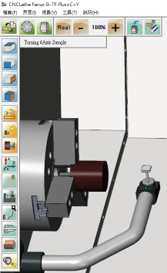

2. Added Z-axis tool setter

- Button travel 48~50mm

- The button lights up when touched

- Collision is considered when the pressure reaches 48mm

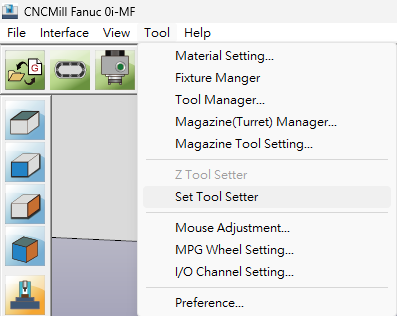

3. Added automatic tool setter function

Example: Enable automatic tool setter function

- Pull-down function menu [Tools] > [Automatic tool presetter position]

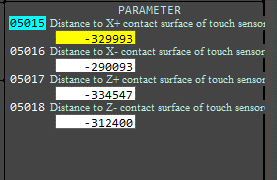

- Check [Enable] and enter the location coordinates

- Press [OK]

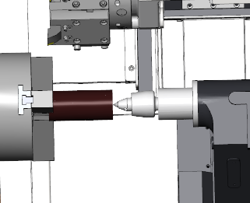

4. Added tailstock and live center movement functions

5. Added an option be above the vise for the tool setter placement.

6. Added G31 Feed Until Skip function

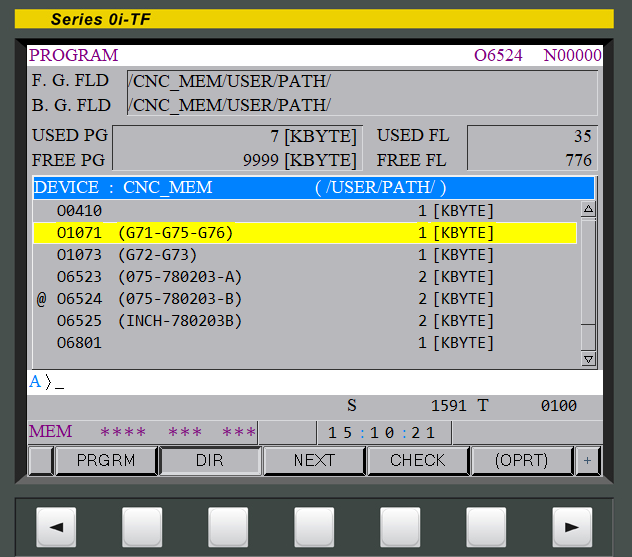

7. Added program delete function

[PROG] > [Directory] > [OPRT] > next page > [Delete]

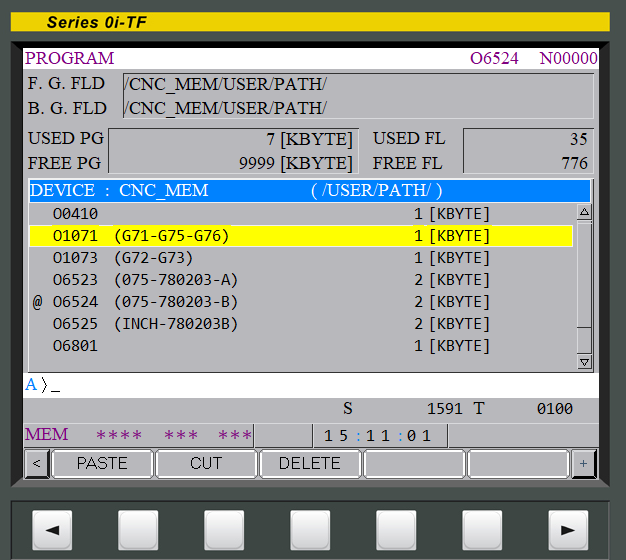

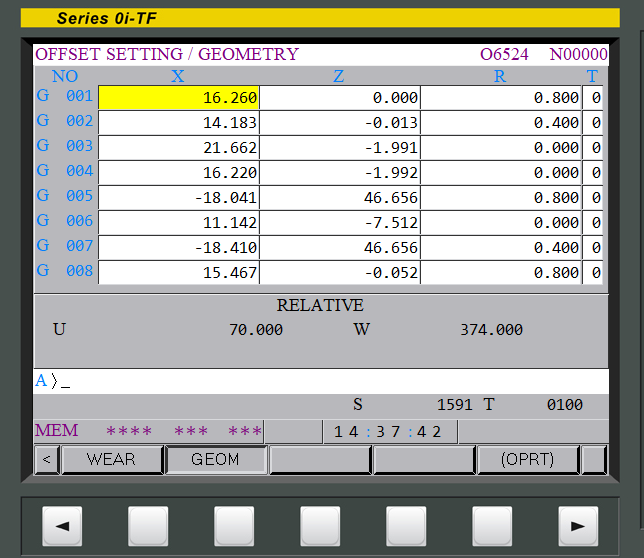

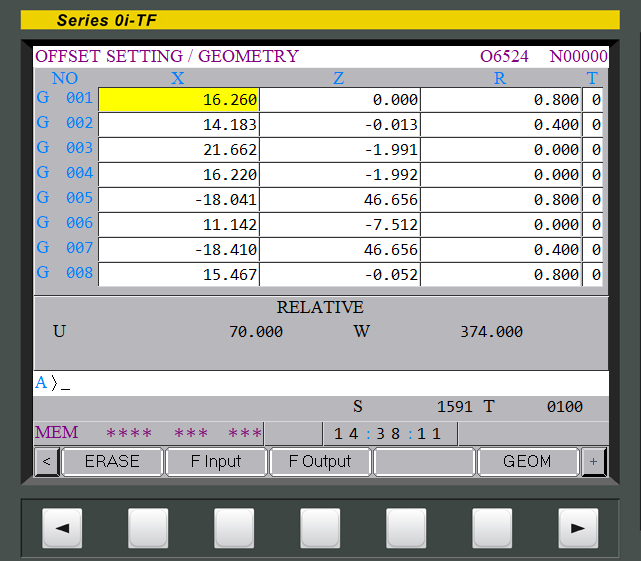

8. Add correction and clear function

[OFFSET] > [OPRT] > next page > [Erase]

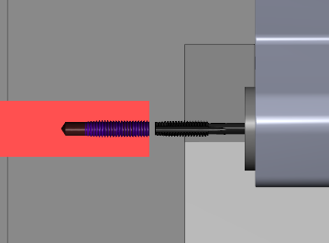

9. Added turning tool screw tapping function

G84: Front tapping cycle

10. At the end of G70, it will return to the starting point of the cycle.

A new action of returning to the starting point of the cycle is added.

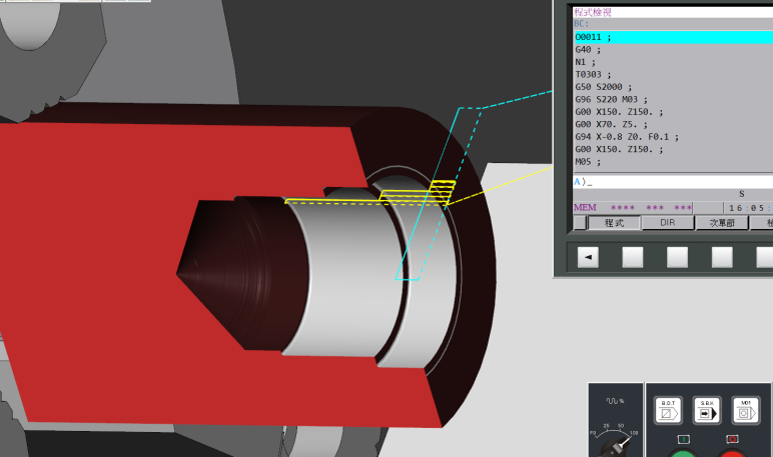

11.Added deep hole tapping mode

G84: Front tapping cycle

G88: Side tapping cycle

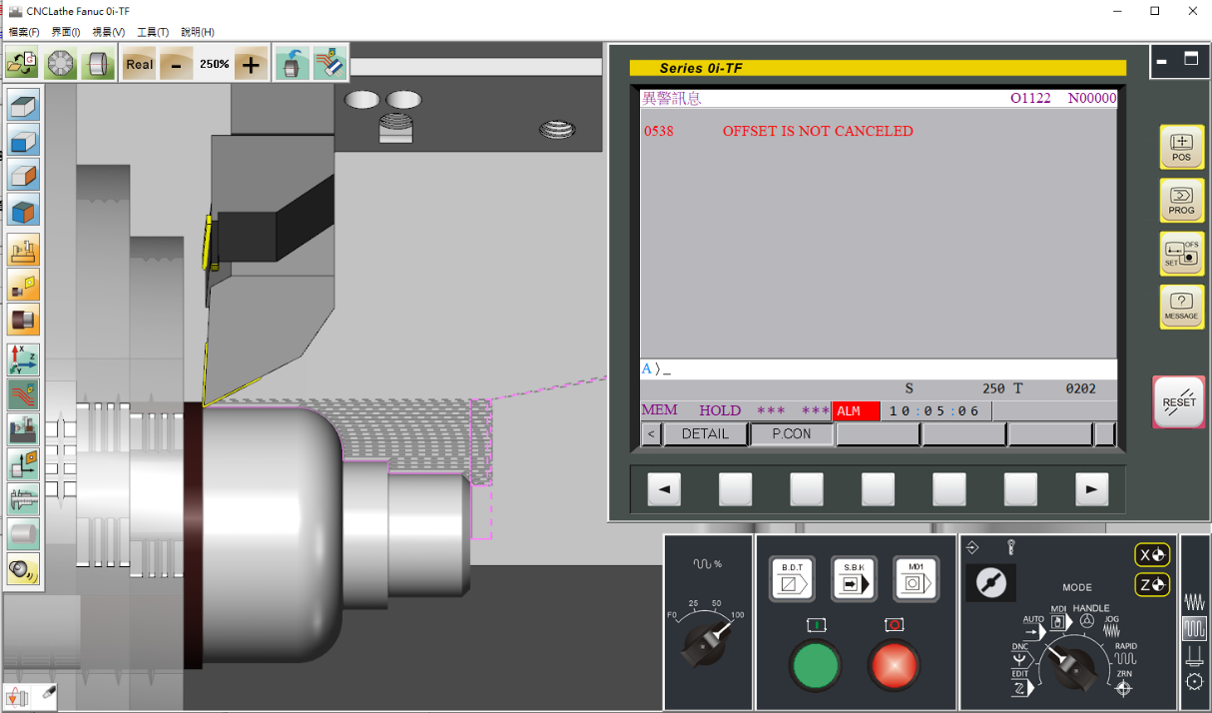

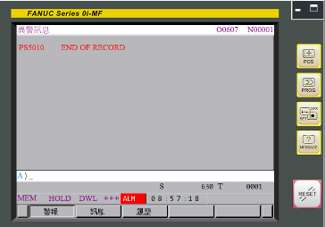

12. When G40 is missing at the end of the contour program, pops up Alarm message PS0538

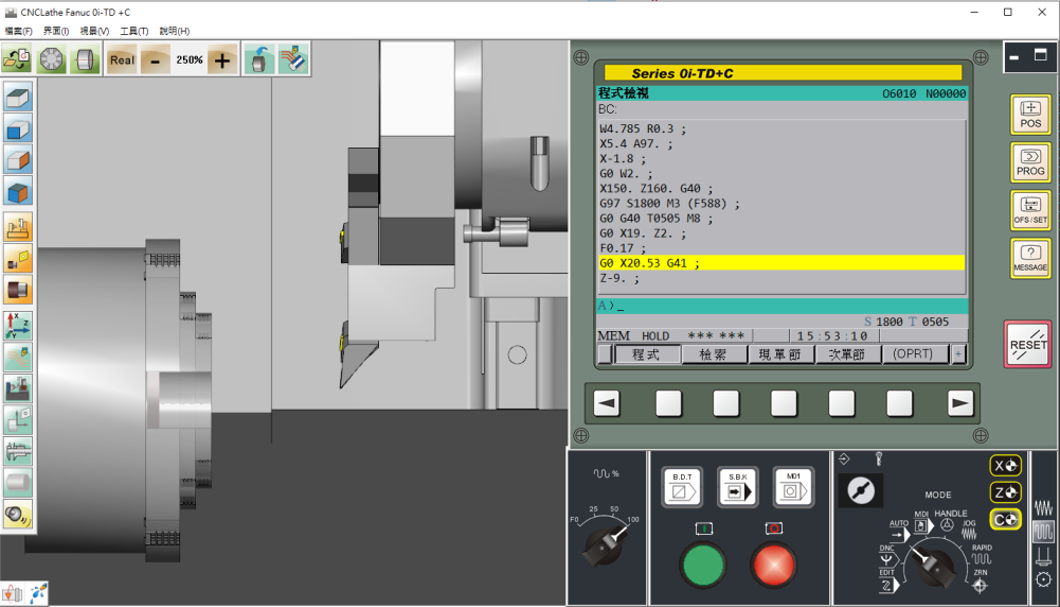

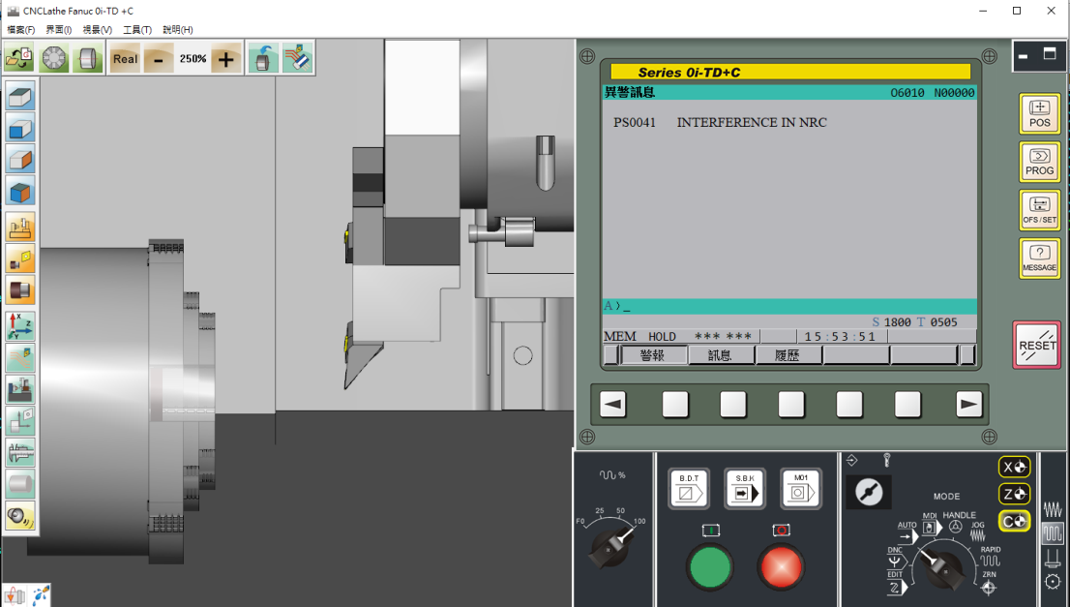

13. Added G41/G42 overcut error message (PS0041)

14. Added spindle overload ALARM

15. When there is no M30 at the end of the program, pops up alarm message PS5010

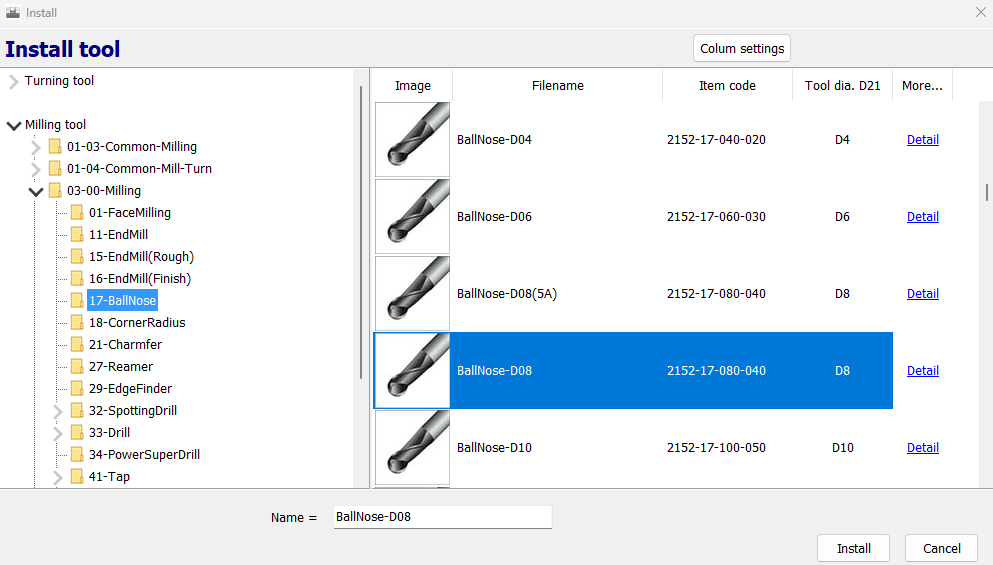

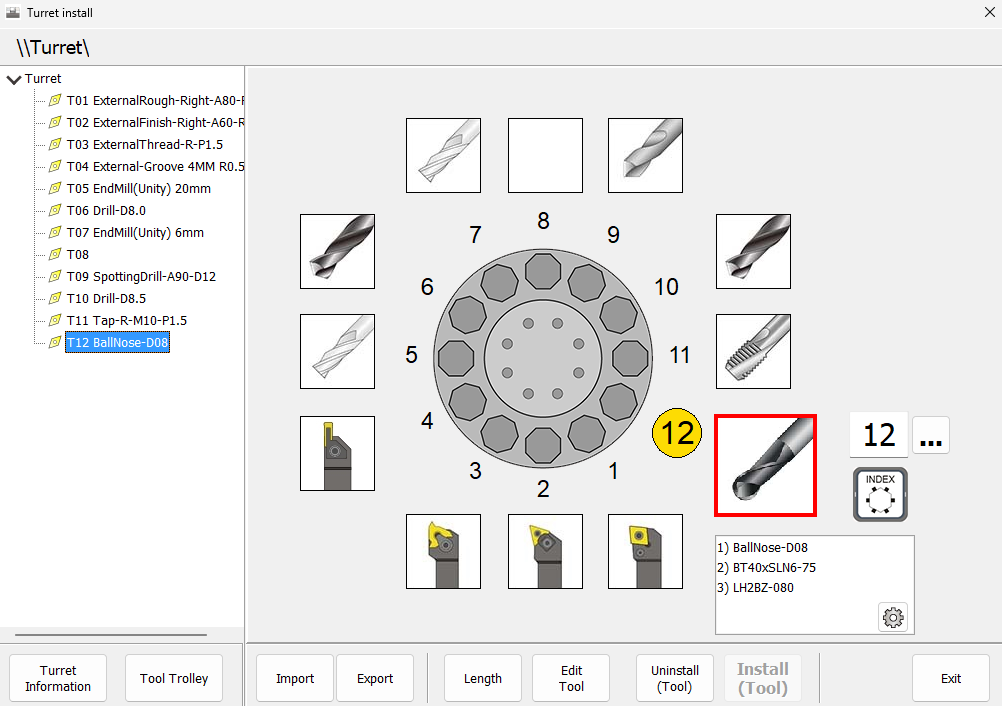

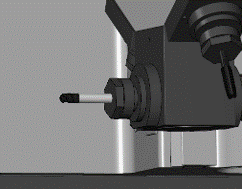

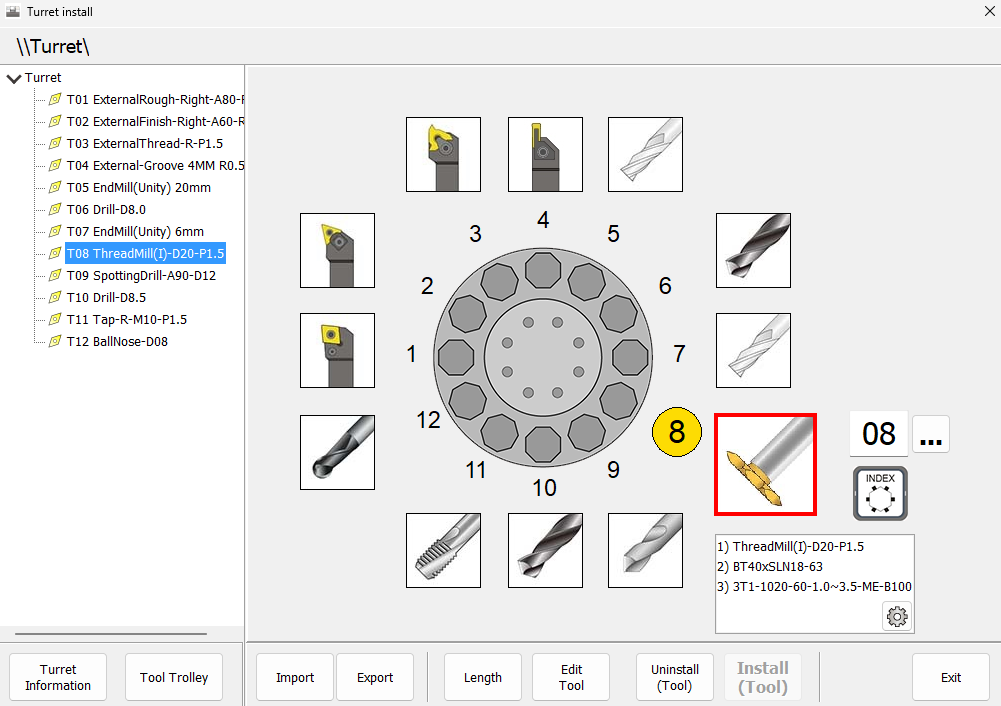

16. Added BallNose milling tool

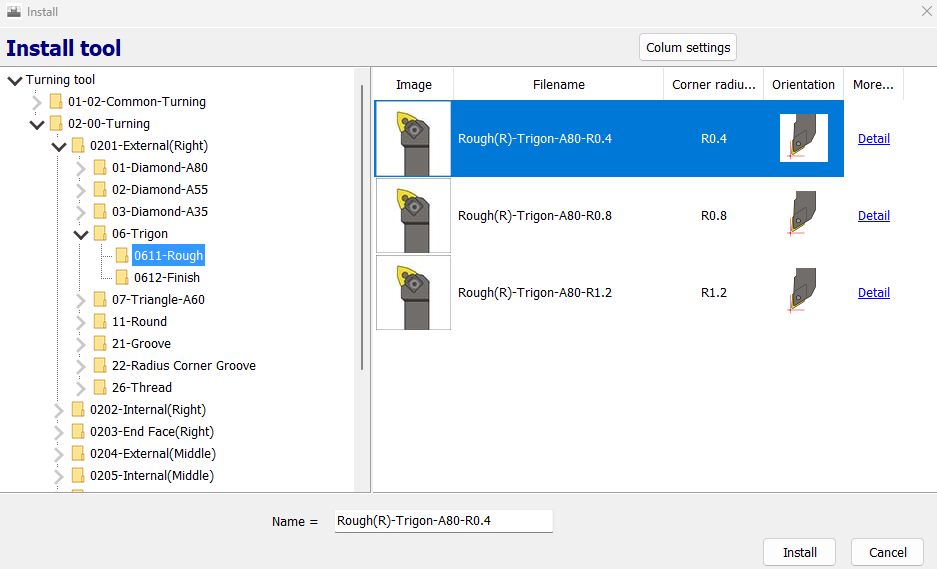

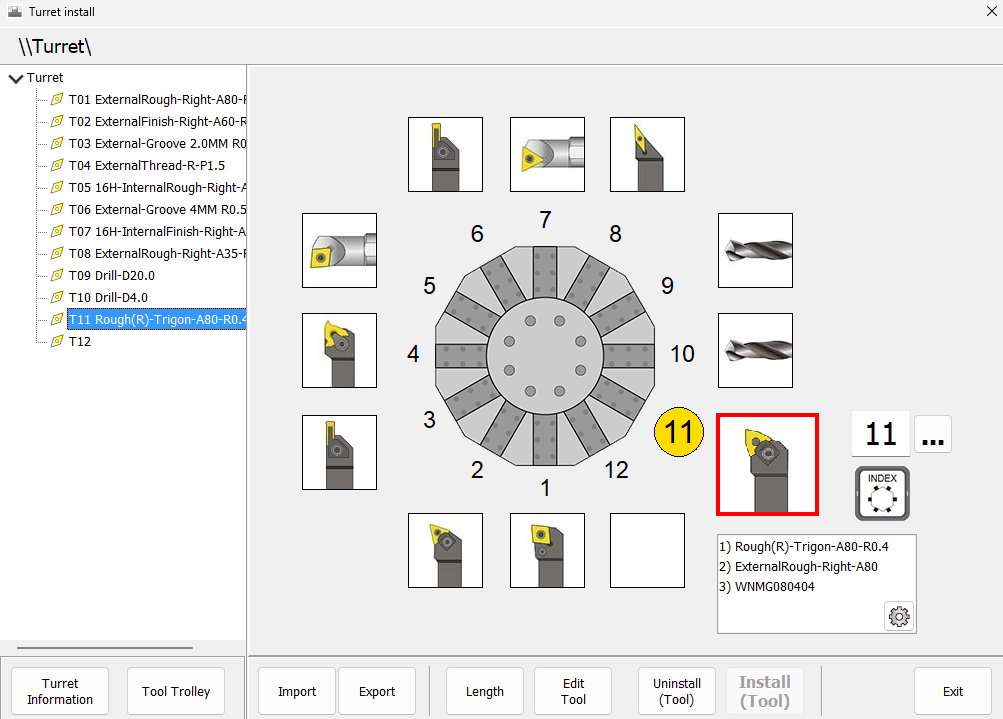

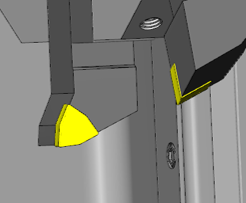

17. Added trigon tool

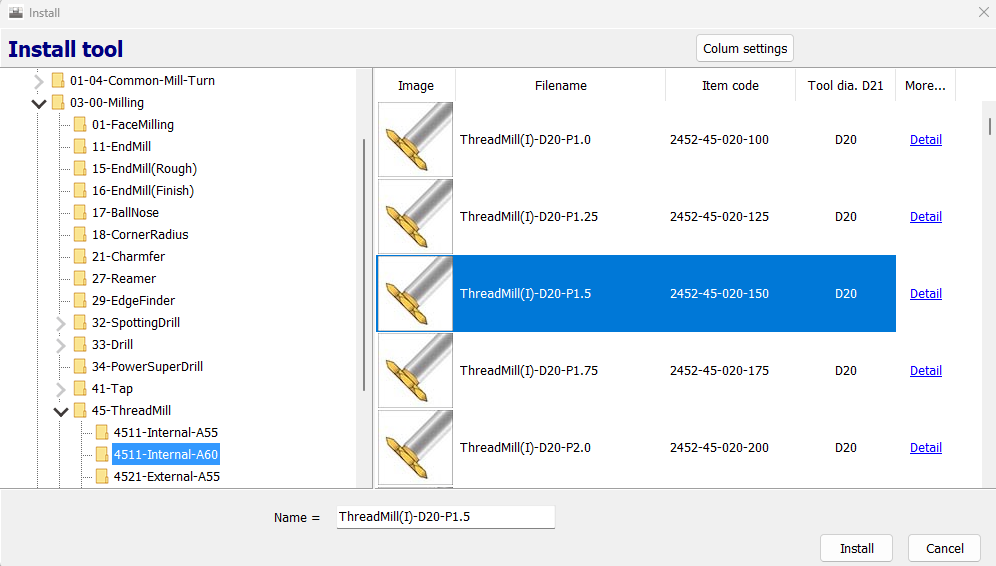

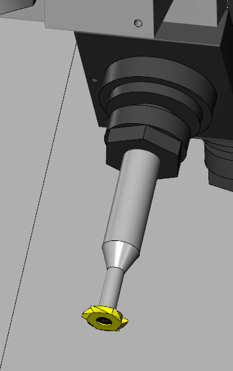

18. Added ThreadMill milling tool

19. Thread measurement, add pitch diameter parallel lines

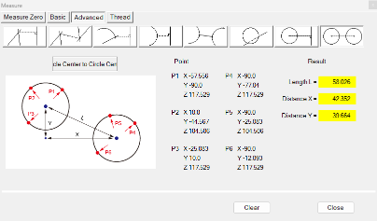

20. When measuring the two circle centers, add distance X and distance Y

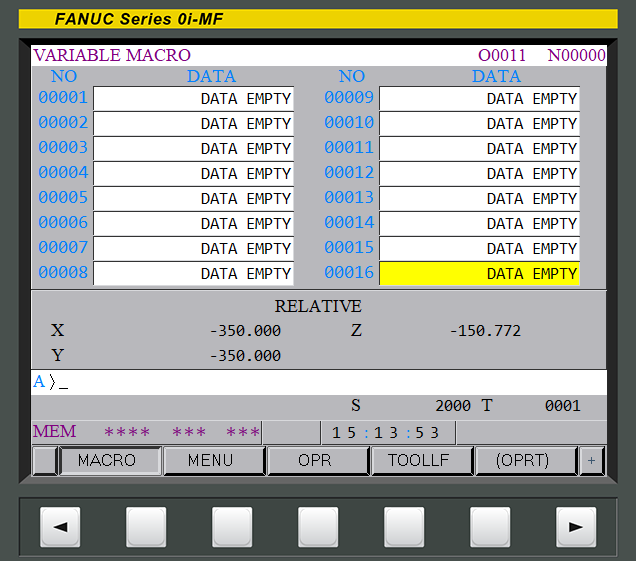

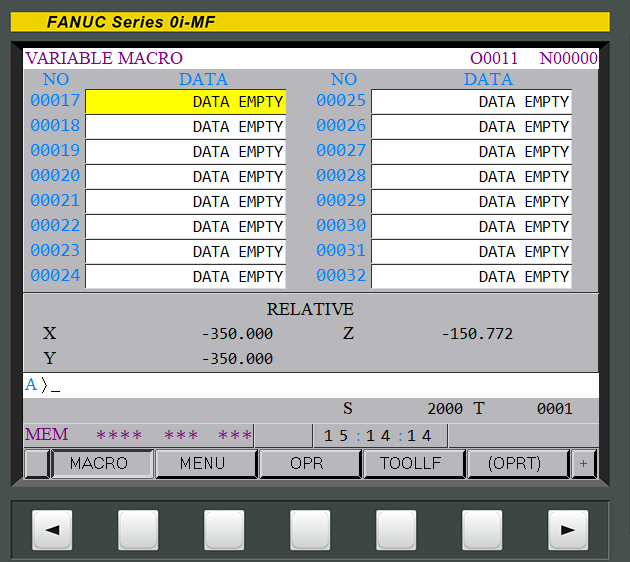

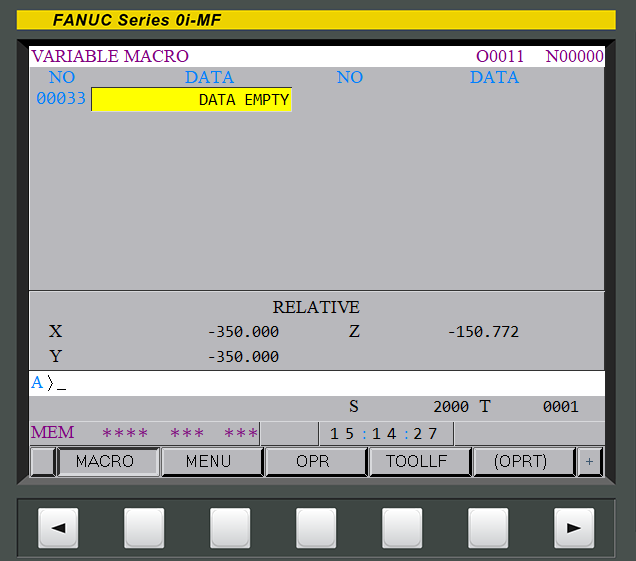

21. Enable Macro parameters #1 - #33 visible

[OFFSET] > next page > [MACRO] > page up & page down to see different parameters

22. Add tool arm parameters setting

23. Disable the tool arm in auto mode.

Disable the tool setting arm in auto mode.

Add warn message after enabling the tool setting arm

(1) Rapid movement mode is invalid

(2) Spindle rotation is invalid

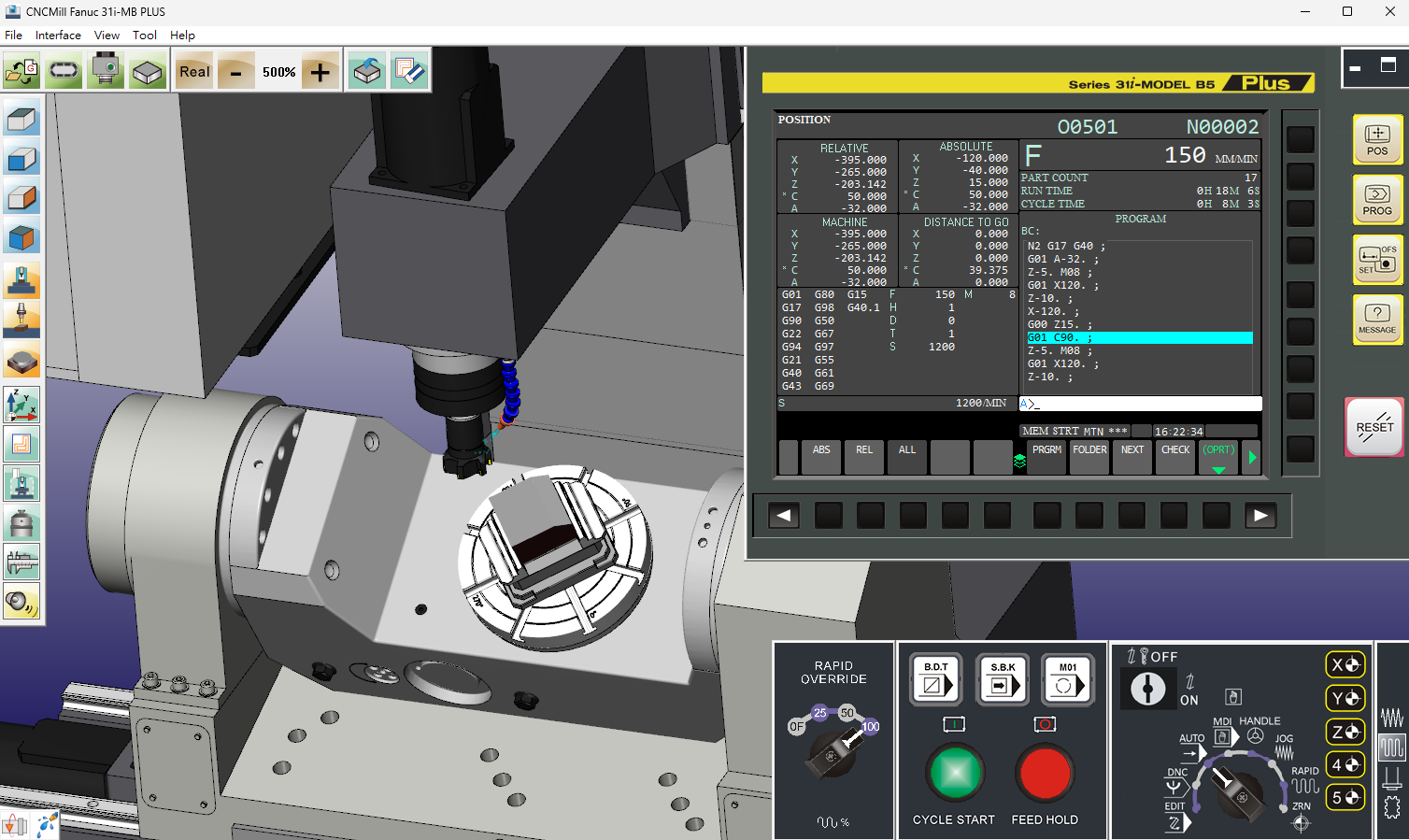

24. Added 31i-MB plus 5A series software

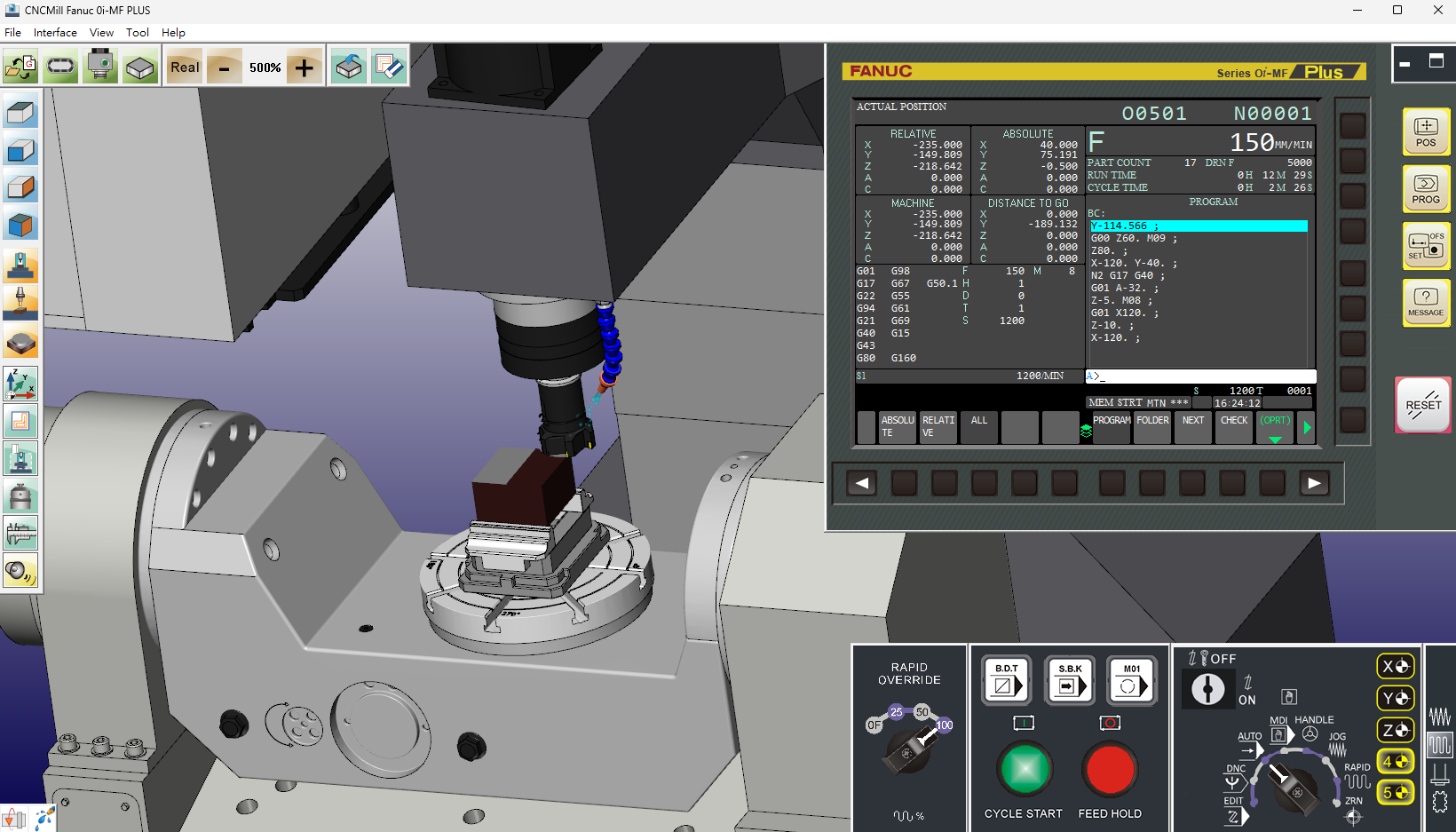

25. Added 0i-MF plus 5A series software

26. 31i-MB controller update interface