Breakthrough Low-Carbon CNC Training: Achieving Less Than 10% Carbon Emissions Through VM, DT, and TM Technologies

today

2024-10-17

local_offer

Case Study

visibility

1021

As global attention to environmental protection and sustainable development grows, the manufacturing industry faces unprecedented challenges and opportunities. While traditional production techniques have made significant progress in improving efficiency and output, they also come with high energy consumption and carbon emissions, severely impacting the environment. Balancing industrial production with environmental protection has become an urgent issue for the manufacturing sector. CNC (Computer Numerical Control) technology, as the core of manufacturing, is undergoing a revolutionary transformation toward low-carbon practices.

RenAn Information Technology Co., Ltd. plays a key role in this low-carbon revolution. Through extensive research and development, RenAn has introduced a low-carbon CNC training program based on Virtual Machine (VM), Digital Twin (DT), and Training Machine (TM) technologies. The primary goal of this program is to leverage virtual technologies to reduce carbon emissions during the production process while maintaining the quality and effectiveness of the training.

Study: Carbon Emission Comparison of VM, DT, and TM Technologies

RenAn's research team conducted extensive experiments and data analysis to test the carbon emissions of VM, DT, and TM technologies and compared them with the carbon emissions of real machines. The results show that CNC training using a Virtual Machine (VM) produces only 4% of the carbon emissions compared to real machines; Digital Twin (DT) technology results in 6%; and the Training Machine (TM) comes in at 8%. In contrast, training with real machines results in 100% of the carbon emissions.

These data indicate that by utilizing virtual technologies for CNC training, carbon emissions can be significantly reduced to less than 10%, greatly decreasing the environmental burden of the manufacturing process.

According to electrical specification label

| specification label (KW) | Virtual Machine (VM) | CNC Workstation (DT) | CNC SImulator (TM) | Real Milling Machine |

| KW | 0.100 KW | 0.405 KW | 0.390 KW | 15.000 KW |

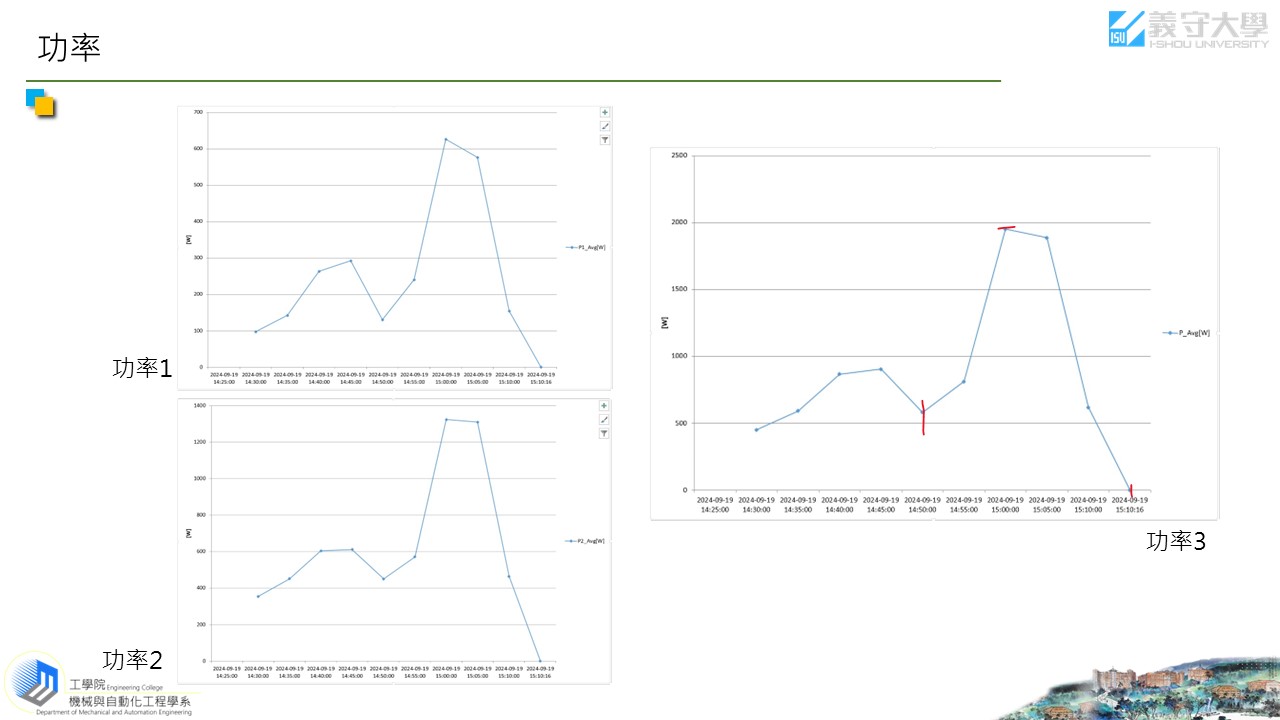

Actual measurement data using a power analyzer

| Actual power consumption (KW) | Virtual Machine (VM) | CNC Workstation (DT) | CNC SImulator (TM) | Real Milling Machine |

| KW | 0.080 KW | 0.120 KW | 0.160 KW | 2.000 KW |

| % | 4% | 6% | 8% | 100% |

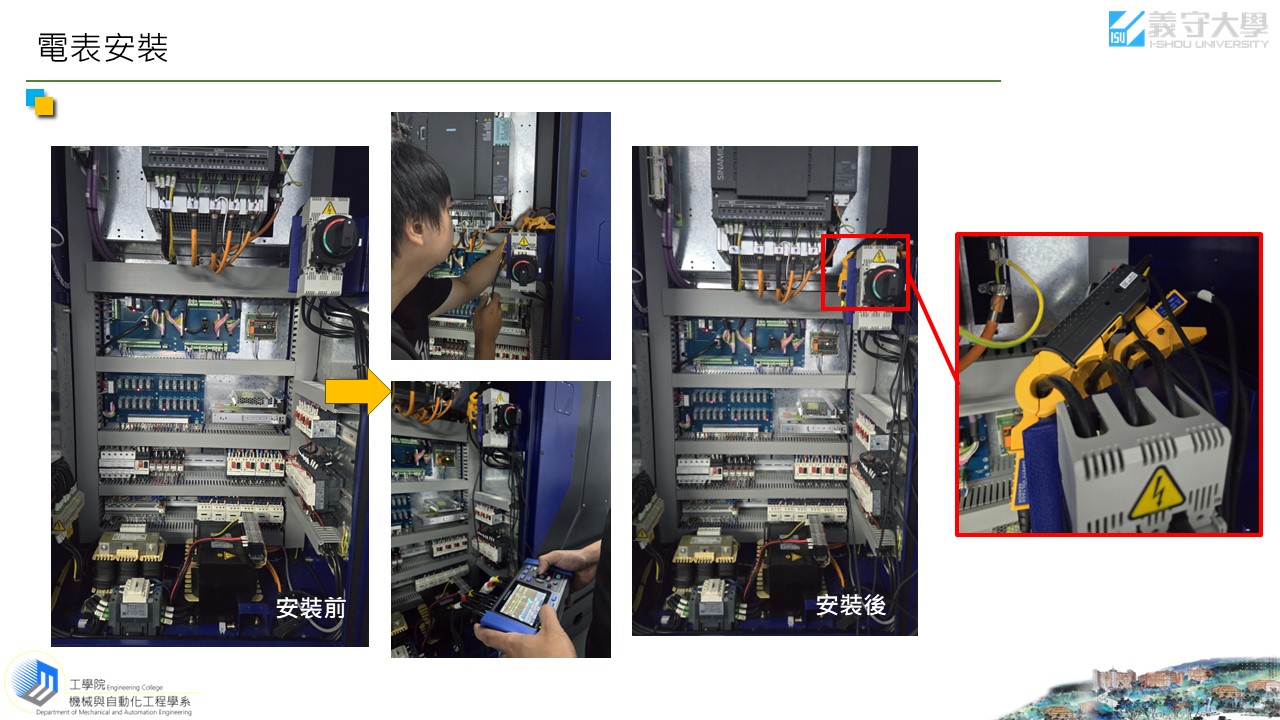

Department of Mechanical and Automation Engineering, I-Shou University

Intelligent Design and Manufacturing Center Yan Alden Assistant Professor Laboratory Assistance Measurement

Key Advantages of VM, DT, and TM

1. Virtual Machine (VM)

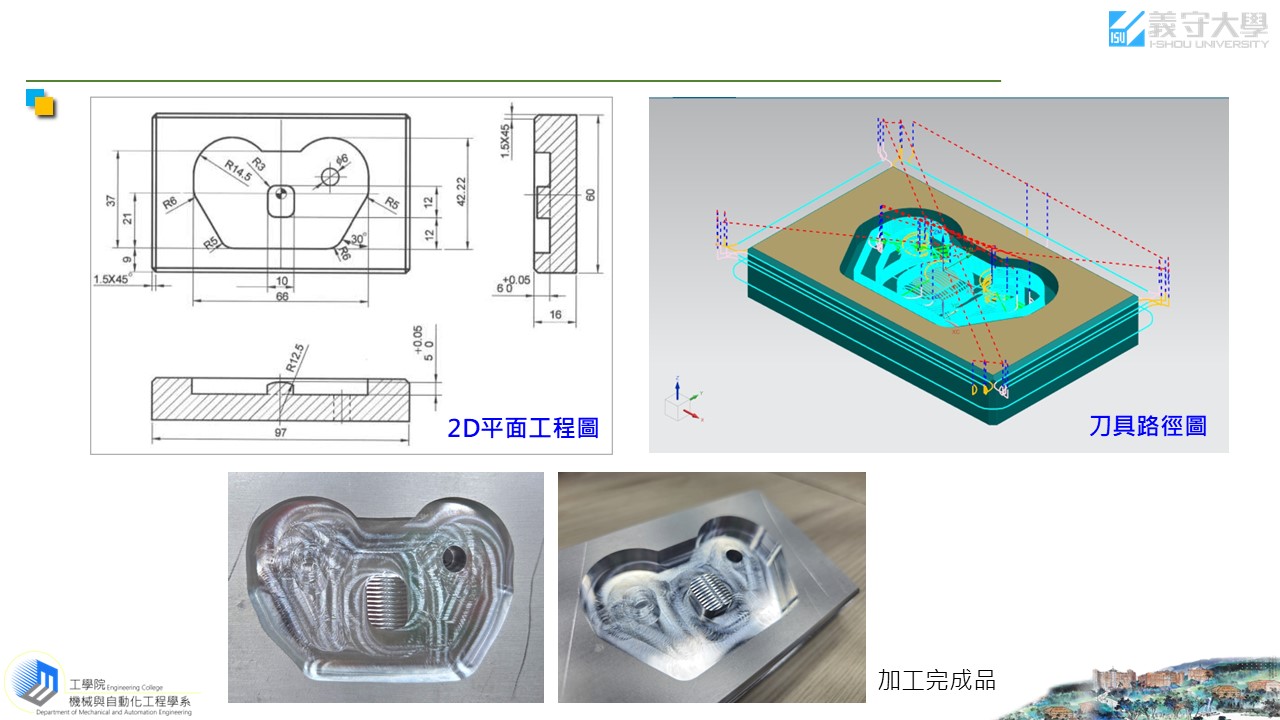

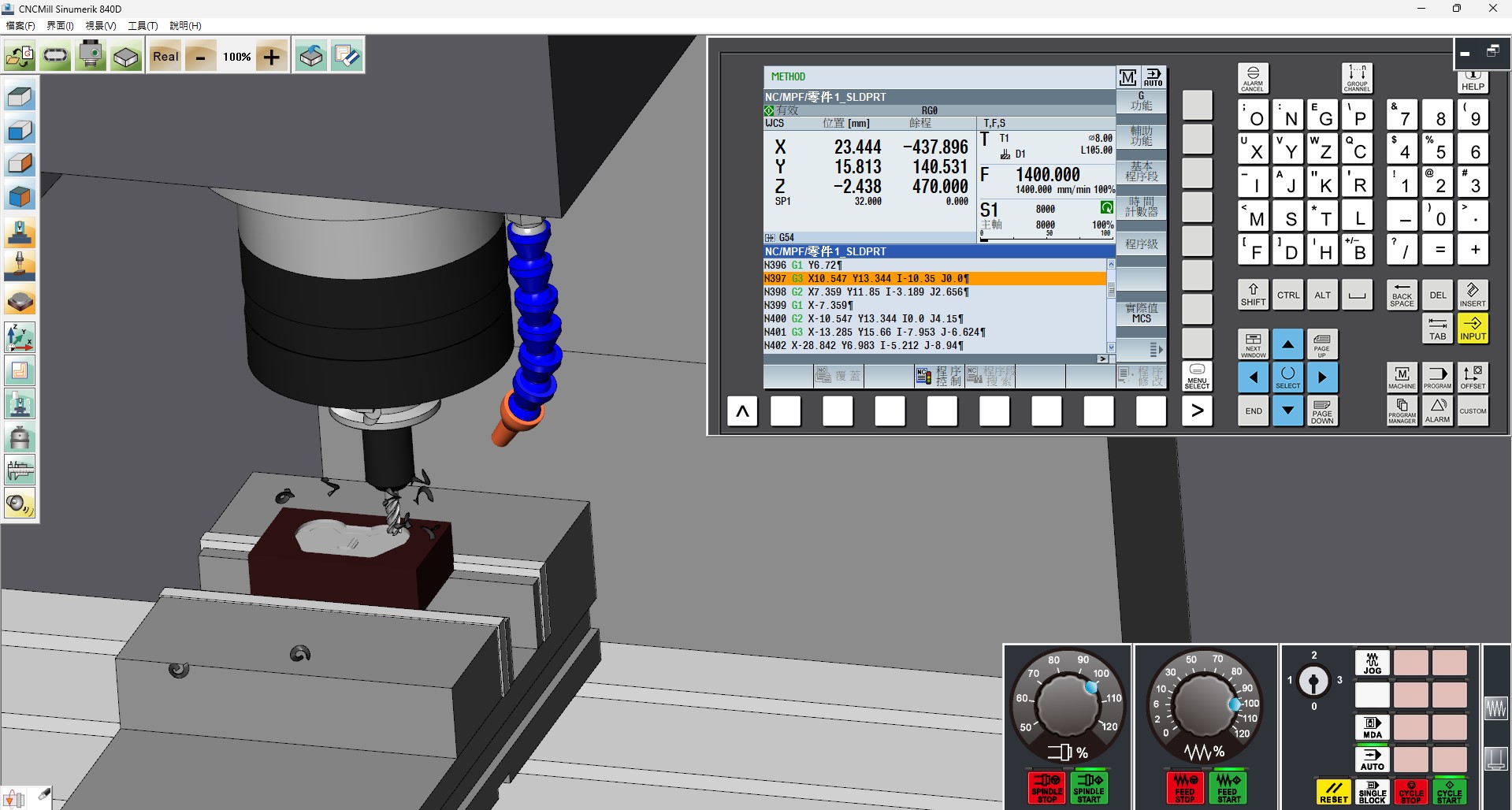

VM technology simulates the real CNC machine operating environment, allowing trainees to practice operations without the need for actual machines. This not only reduces energy consumption but also avoids potential equipment wear and tear during training, significantly lowering carbon emissions in the process.

2. CNC Operation Simulation Workstation (DT)

DT technology uses digital replicas of CNC machines to simulate real equipment operations and behaviors in real-time. Trainees can learn and operate these digital twins in a virtual environment, experiencing operations similar to real equipment while reducing reliance on physical machines, thereby cutting down energy consumption and emissions.

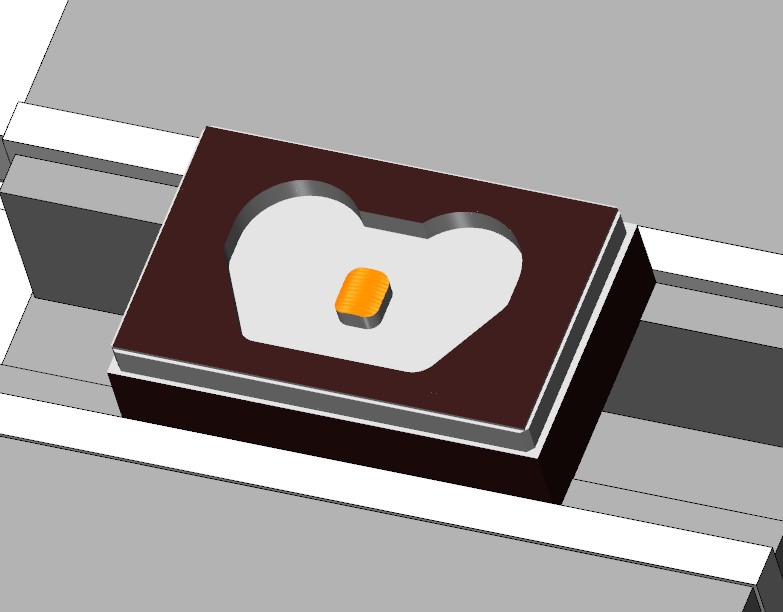

3. CNC Simulator (TM)

TM technology focuses on process simulation and data prediction, helping trainees understand each step of the CNC manufacturing process and its impact on energy consumption. This simulation not only raises awareness of energy conservation but also aids in further optimizing CNC machining programs, ultimately reducing energy usage.

Implementation and Future Outlook of Low-Carbon CNC Training

RenAn’s technical team has not only achieved technological breakthroughs but is also committed to applying these advancements in practical CNC training courses. The low-carbon CNC training program aligns with the modern manufacturing industry's environmental demands and provides a viable path for global manufacturers to save energy and reduce carbon emissions.

As CNC technology continues to evolve, Virtual Machines, CNC workstation, and CNC simulator will play an increasingly important role in both training and production. With the continuous optimization of these technologies, we have every reason to believe that future CNC training will further lower carbon emissions and achieve true green manufacturing.

文章區塊