How CNC Simulators Help Schools Modernize Training Without Breaking the Budget

today

2025-08-19

local_offer

CNC Machining Knowledge

visibility

664

Introduction:

In today's fast-changing manufacturing world, educators face mounting pressure to update CNC training programs—often with shrinking budgets. As industries embrace automation and precision engineering, the demand for skilled CNC professionals is higher than ever.

But many schools hit a wall: how do you offer hands-on, cutting-edge CNC training without spending on expensive machines, expanding lab space, or hiring more staff?

CNC simulation technology is the answer. Simulators like RenAn's are helping vocational centers and technical institutes deliver immersive, industry-relevant training—without the high costs or physical constraints of traditional labs. Even better, they’re improving student outcomes while keeping budgets intact.

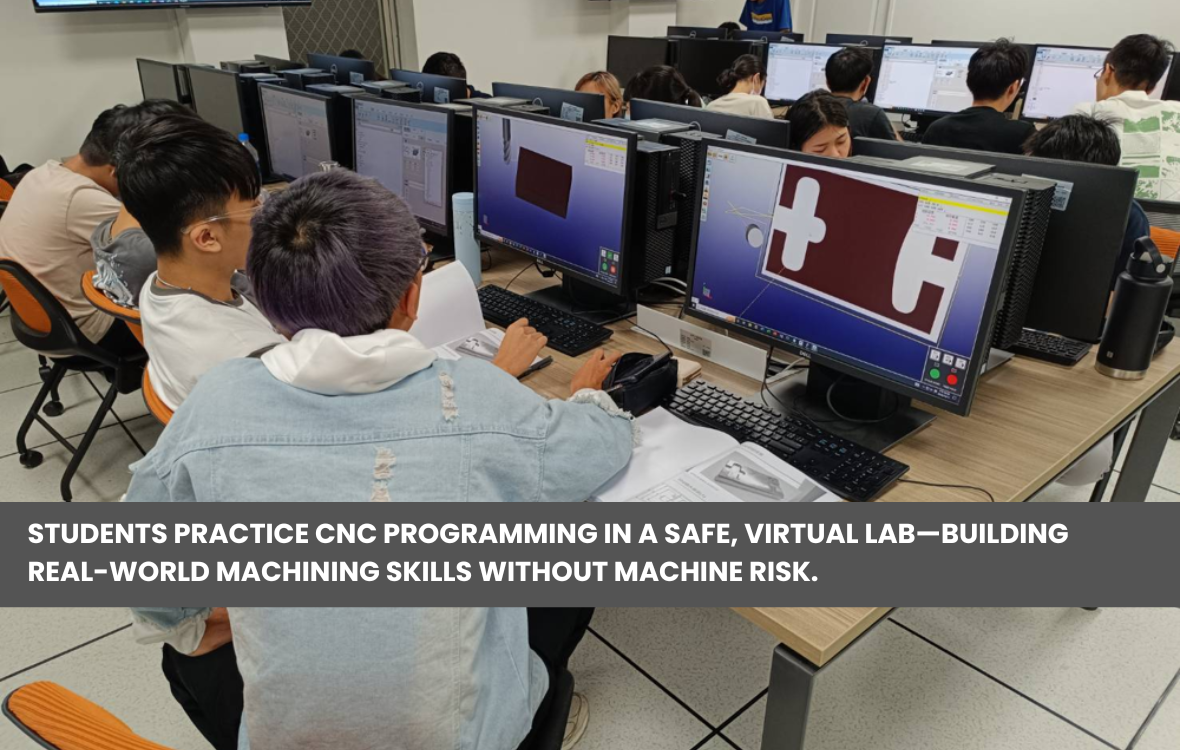

1.Virtual Labs, Real-World Skills

RenAn's CNC simulators replicate real-world machining—milling, turning, G-code programming, toolpath verification, and more. Students gain practical experience in a safe, repeatable environment, building confidence before they ever touch a machine.

Simulation removes the bottlenecks of limited lab access and tool damage risk. Students can train independently, anytime, enabling blended learning models that combine classroom theory with virtual hands-on practice—maximizing retention and skill development.

2.Expand Training, Not Costs

Traditional CNC labs come with recurring costs: machine maintenance, tool wear, safety protocols, and instructor time. For many schools, scaling up is financially out of reach.

With RenAn's simulators, one software license can support multiple classes, campuses, or training tracks—without new equipment or space. Institutions cut costs on consumables and reduce downtime, all while serving more students with fewer resources.

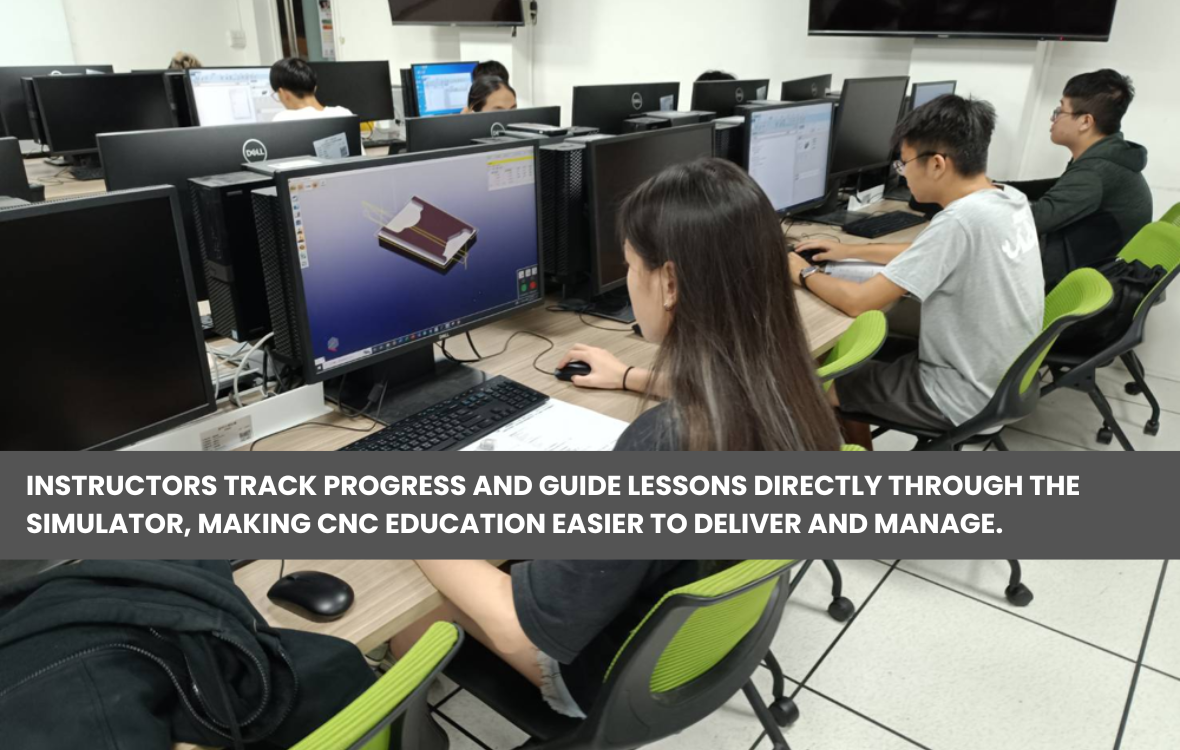

3.Simplified Curriculum Delivery

CNC simulation isn’t just a student tool—it's a teaching asset. Instructors can assign real-world machining projects, track progress, and provide feedback directly through the software.

RenAn supports training paths from beginner to advanced, including multi-axis operations. This customization keeps programs aligned with both educational goals and evolving industry needs.

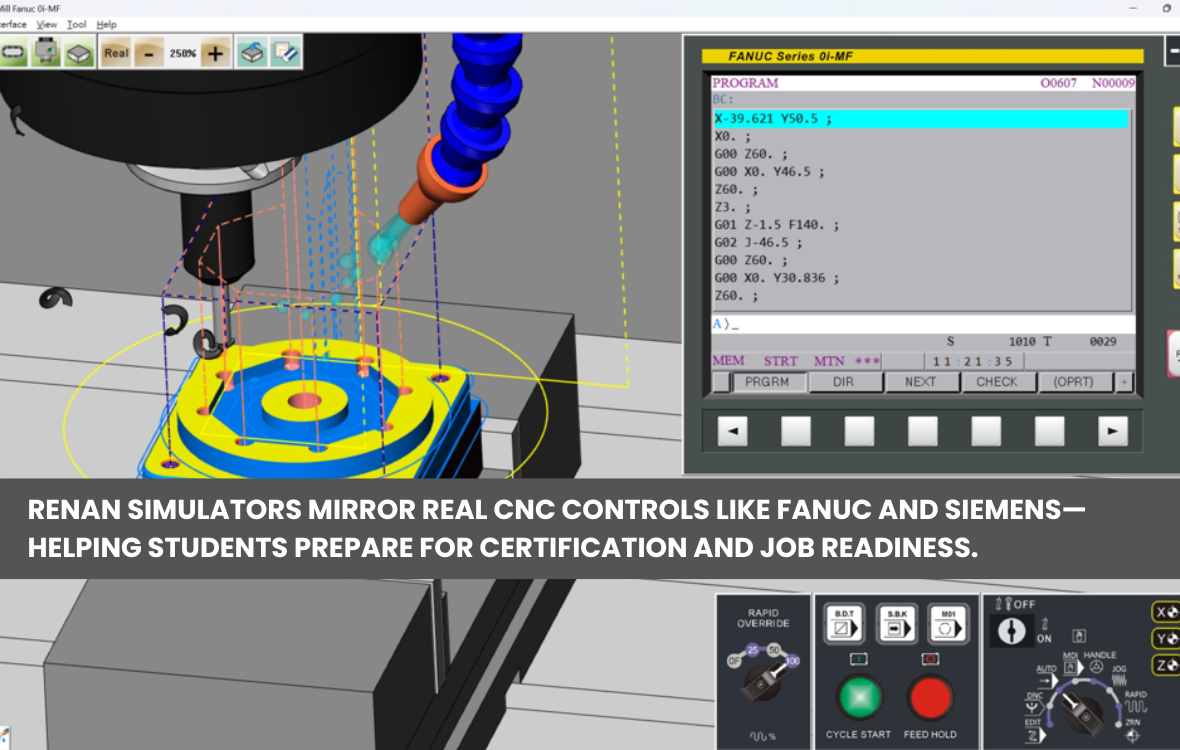

4.Industry-Aligned, Certification-Ready

RenAn simulators mirror the logic and interfaces of real CNC controls—FANUC, Siemens, Mitsubishi, and others—giving students familiarity with tools used in actual shops.

This real-world exposure boosts readiness for certification exams and job placements. Many graduates report smoother transitions into apprenticeships thanks to their hands-on simulator experience.

5.Scale Across Campuses and Classrooms

For institutions with multiple locations, simulators offer a standardized, scalable solution. Instead of duplicating expensive hardware, schools can deliver consistent training quality across all sites—ideal for meeting accreditation standards and improving teaching efficiency.

6.Built for Hybrid and Distance Learning

Today's education isn't bound to four walls. Simulation-based training allows students to access CNC practice from school labs or home, supporting hybrid models, evening classes, or remote learners in underserved regions.

With flexible access, programs can reach more students—including adult learners and working professionals—without investing in additional facilities.

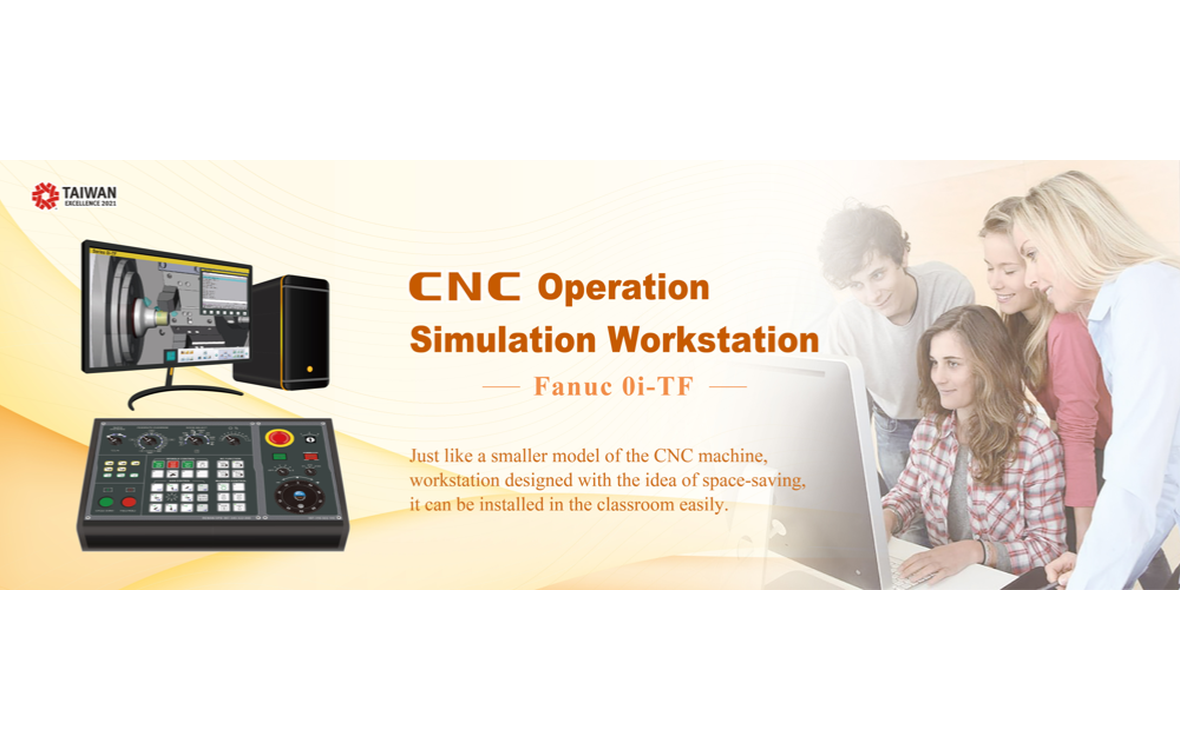

7.Easy Setup, Ongoing Support

RenAn's platform installs on standard Windows systems, supports multiple languages, and offers regular updates to enhance usability and expand machine compatibility.

Schools also receive reliable technical support and instructional guidance, ensuring smooth adoption and long-term value.

Conclusion:

Expanding your CNC training program doesn't require expanding your infrastructure. RenAn's simulators give schools the ability to train more students, deliver higher-quality instruction, and align with industry standards—without the heavy financial burden of traditional labs.

Whether you're launching a new course or growing an existing one, simulation offers a smart, scalable, and sustainable path forward.

Call to Action:

Want to transform your CNC training—without overspending?

👉 Contact RenAn today to book a free demo or claim your 15-day trial license.

Let's bring hands-on, future-ready CNC education to every classroom.

文章區塊