All

CNC Training and Skill Development

Five Ladder CNC Training Courses

Ladder 1 CNC Basic Knowledge and Manual Programming

Ladder 2 CNC Controller Operation

Ladder 3 CADCAM Software

Ladder 4 CNC Ability Checking

CNC machining software

replyBack

FrankCAM Turning

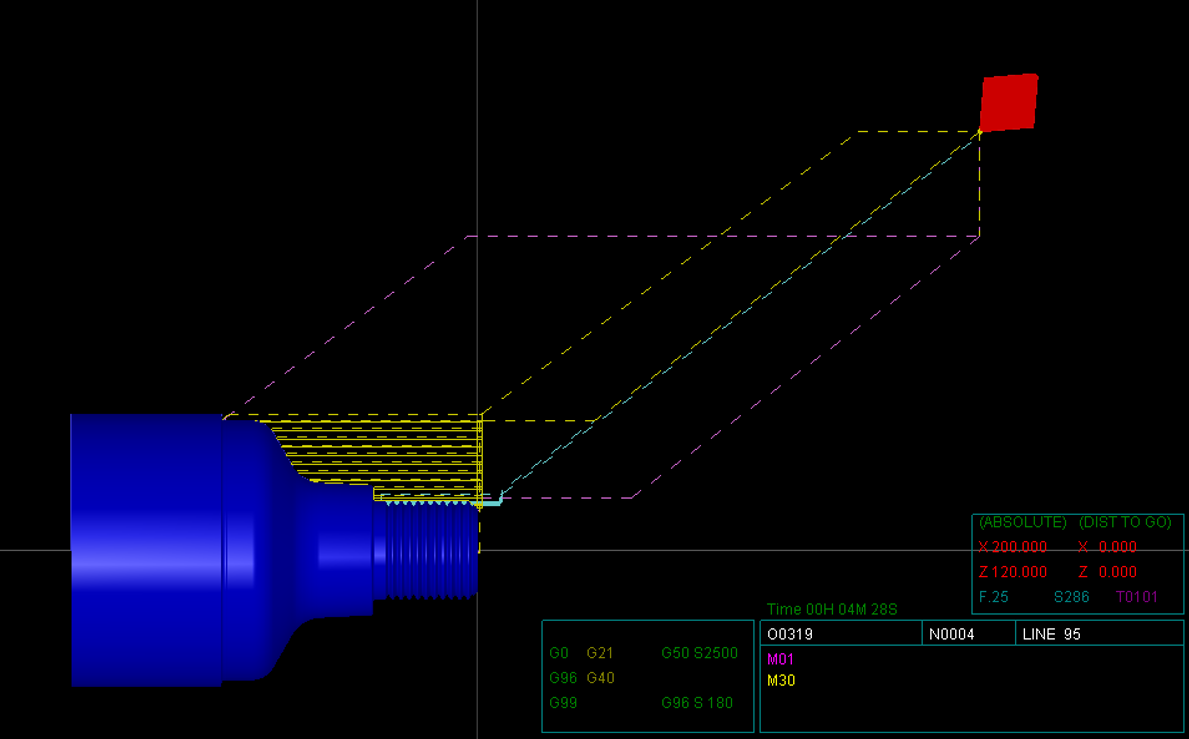

+Simulation

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time.

Excellent tool for learning CAD/CAM and verifying with simulation.

Excellent tool for learning CAD/CAM and verifying with simulation.

FrankCAM Turning

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time. Excellent tool for learning CAD/CAM and verifying with simulation.

Feature 1

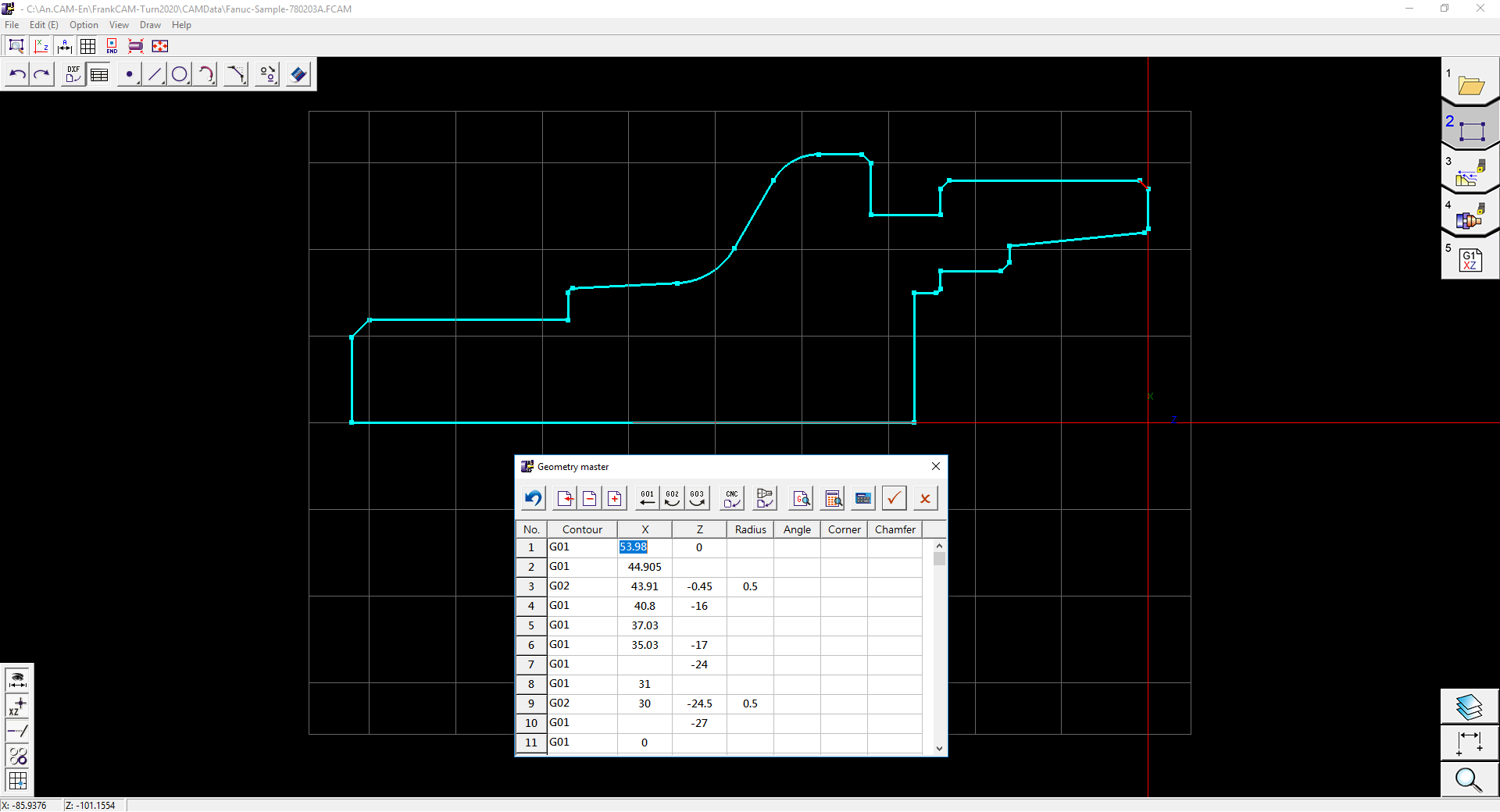

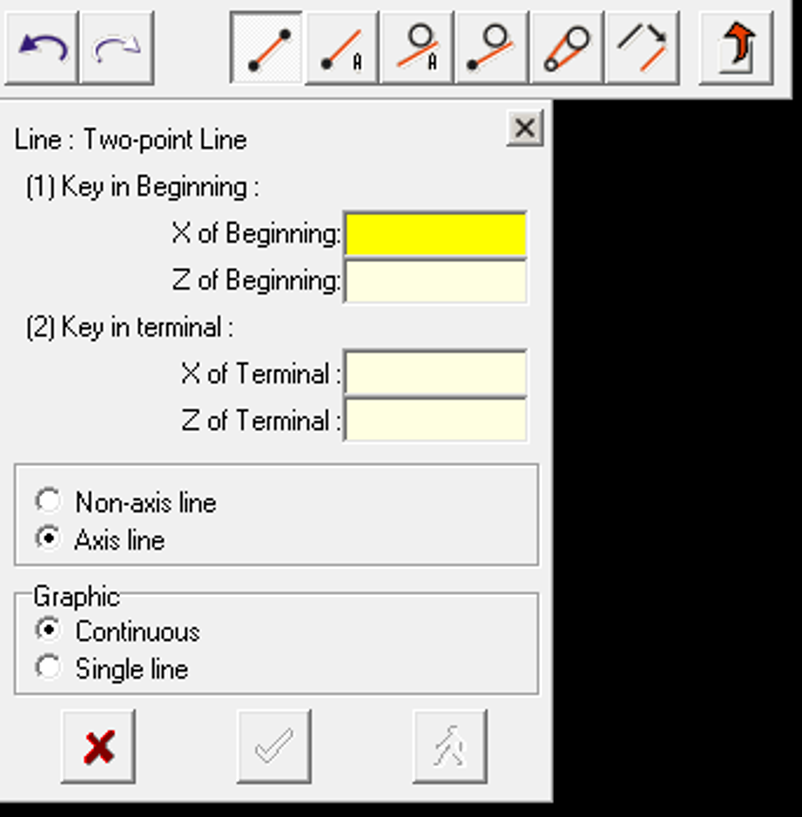

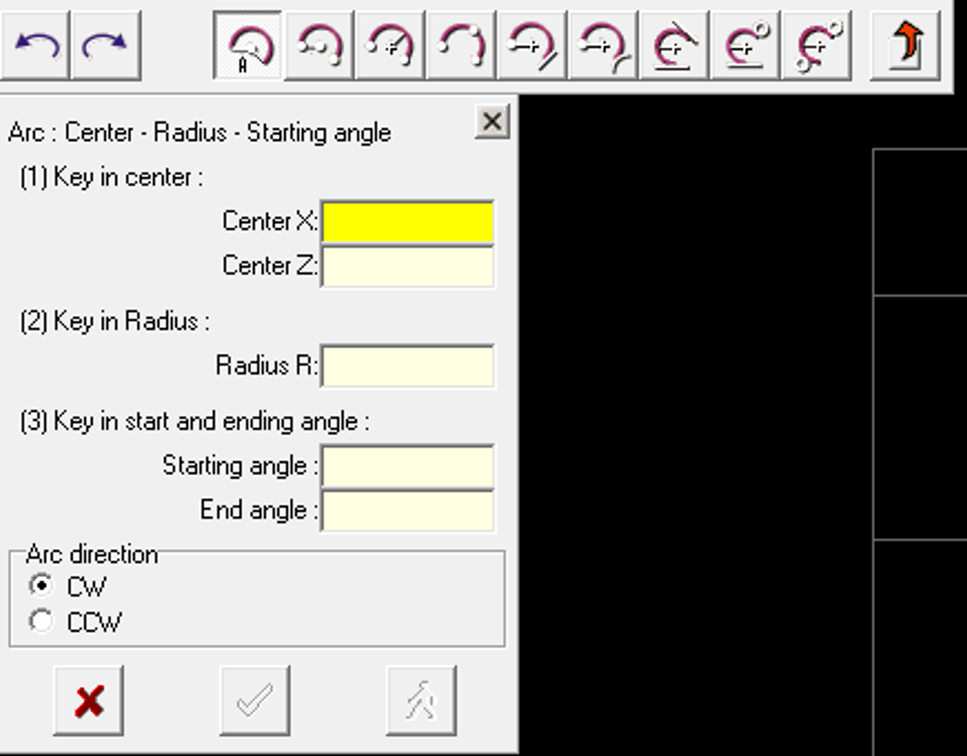

Solve the problem while you couldn't get the drawing.

You only need to key in coordinate and the contour is finished with Geometry Master

Feature 2

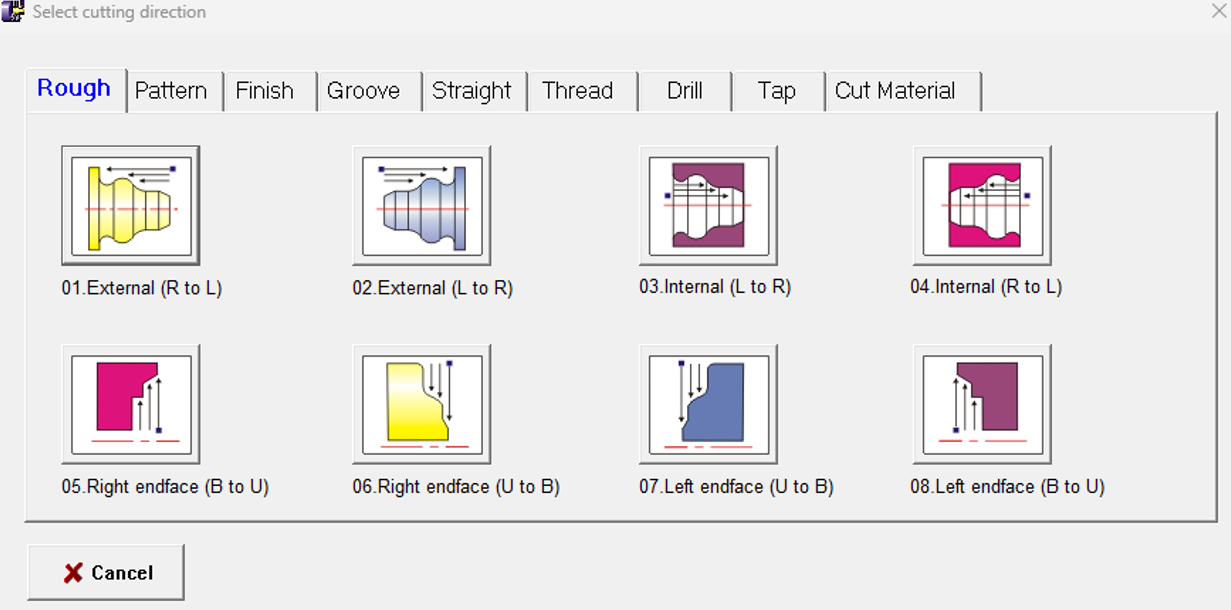

Select processing method with visual representation, make the setting straightforward and efficient.

Feature 3

It's easy to adjust the processing priority by select and drag the setting.

Feature 4

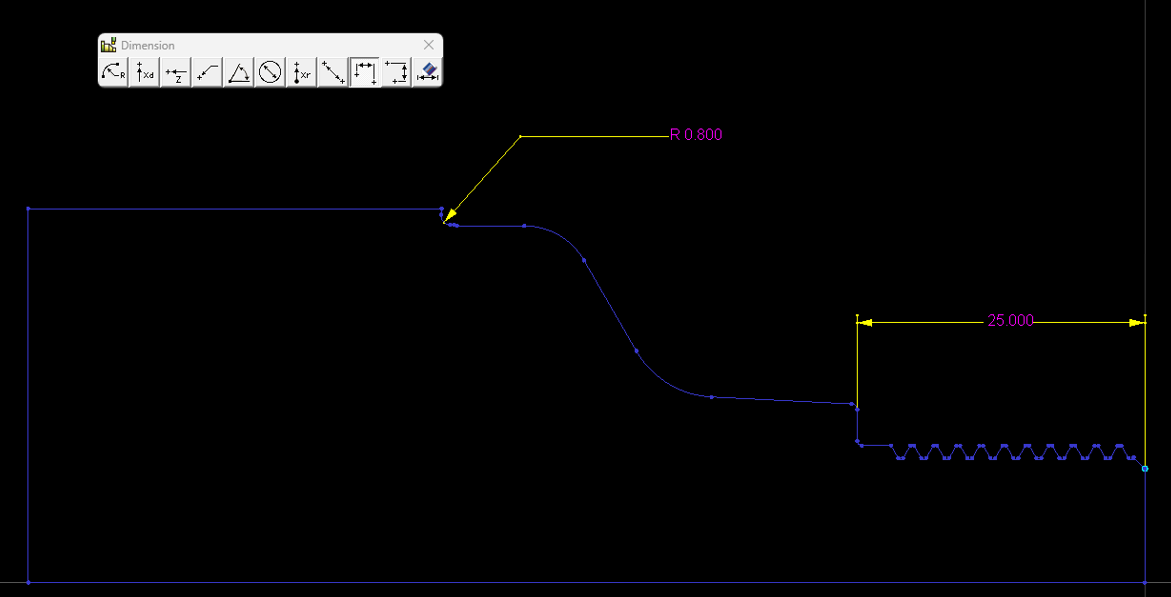

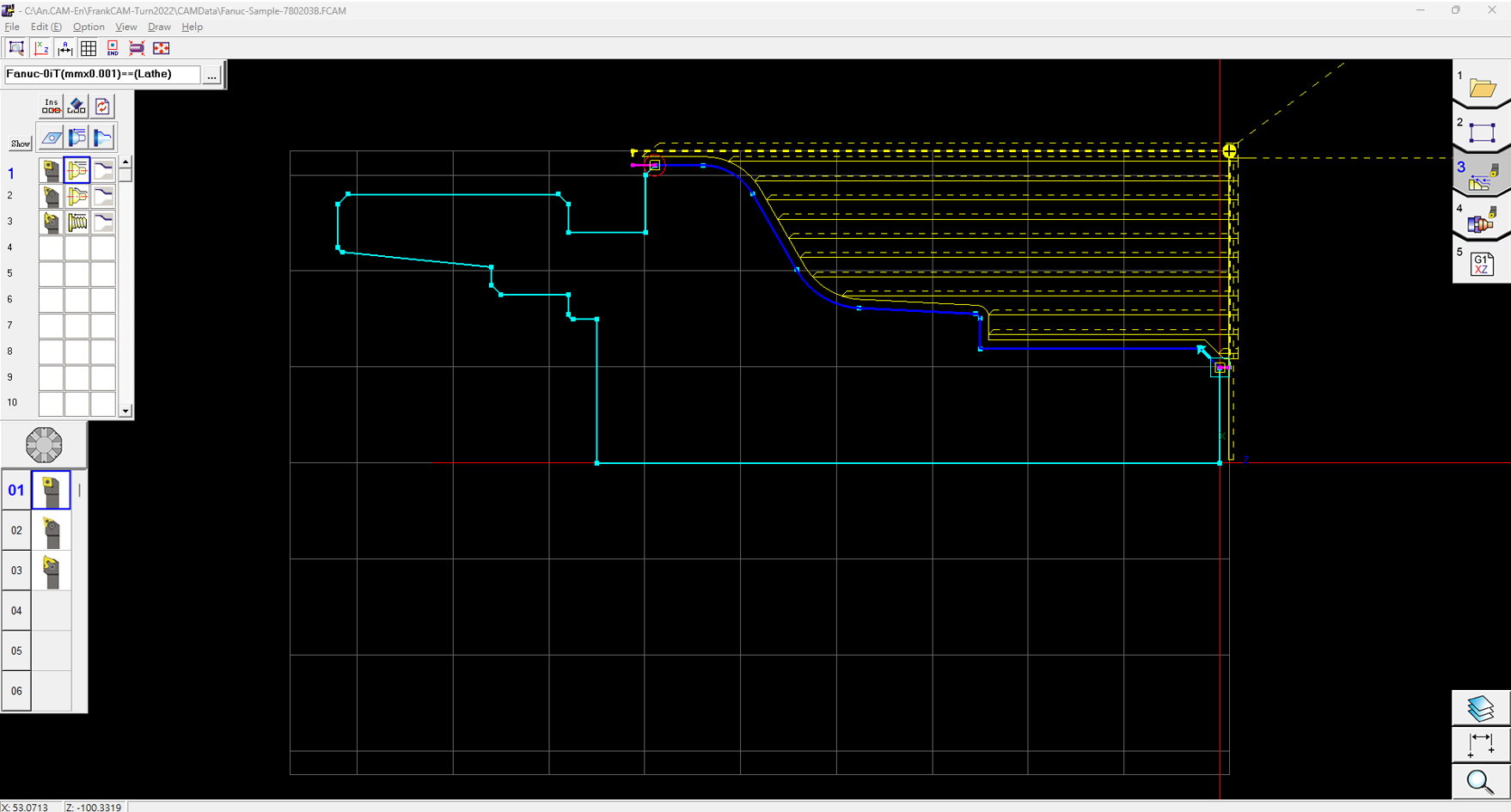

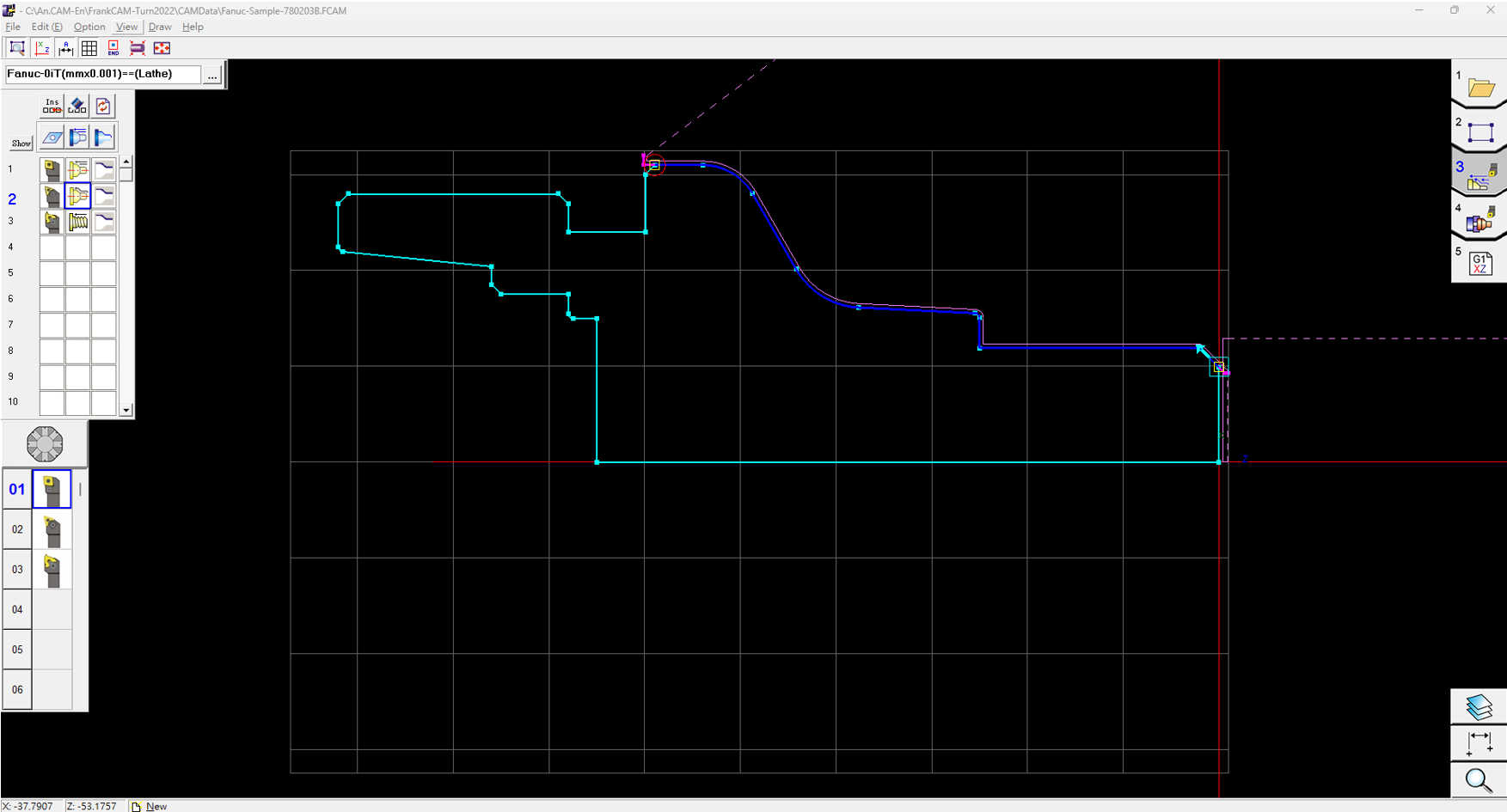

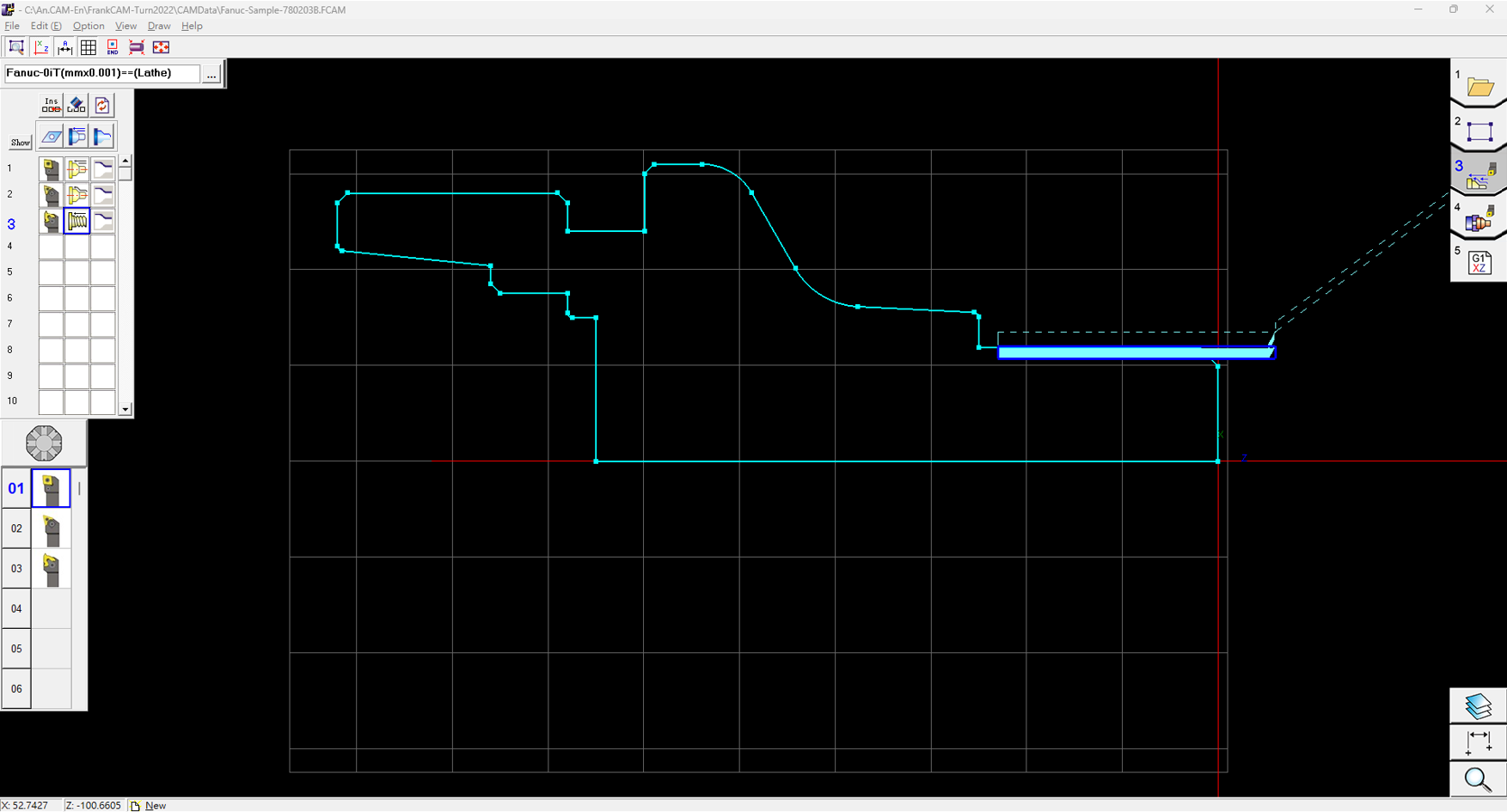

The toolpath is very clear with each tool in different color.

Feature 5

Dimension checking function make the accuracy improvement easier.

Feature 6

The drawing button is assisted by icons, which can help users have a clearer concept of drawing when inputting parameters and is more intuitive to use.

Drawing function:

Point, line, circle, arc, chamfering, mirror, rotate etc and import DXF file.

Feature 7

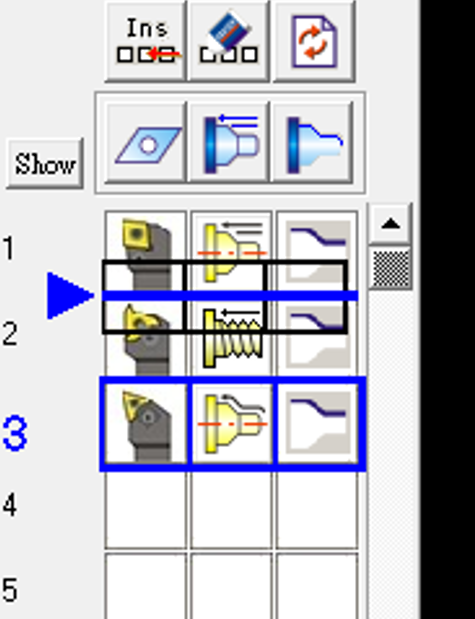

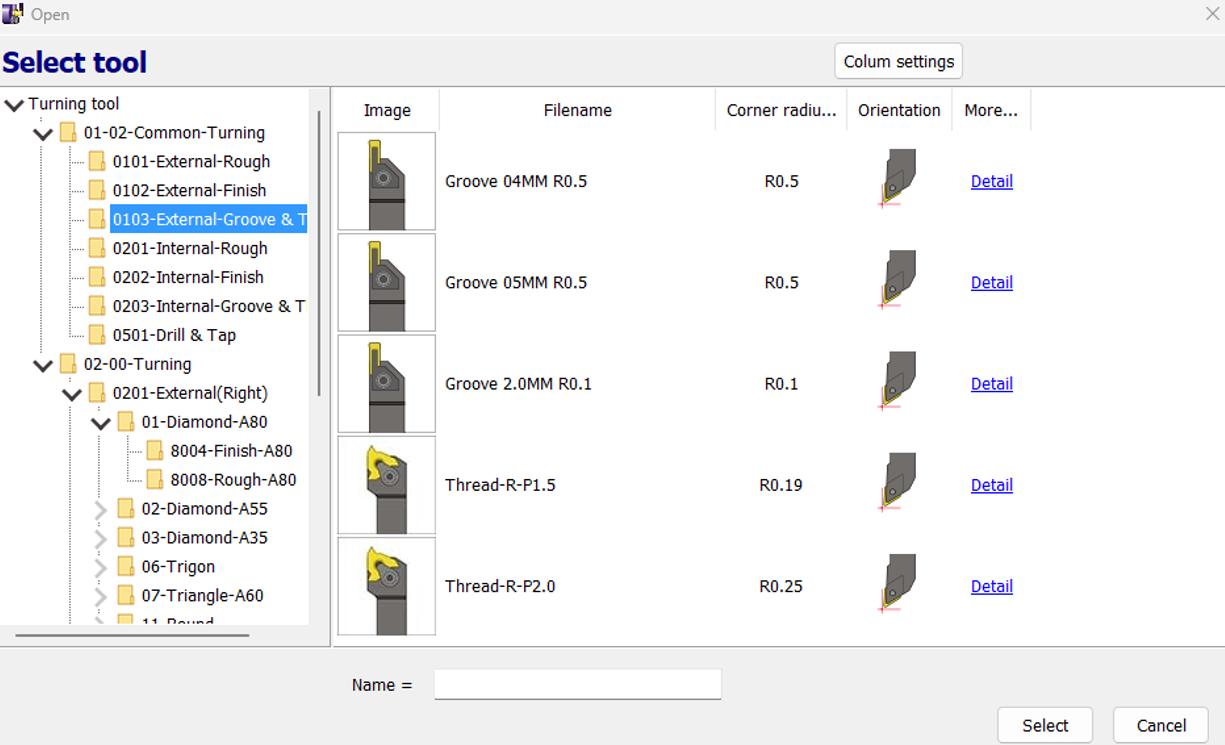

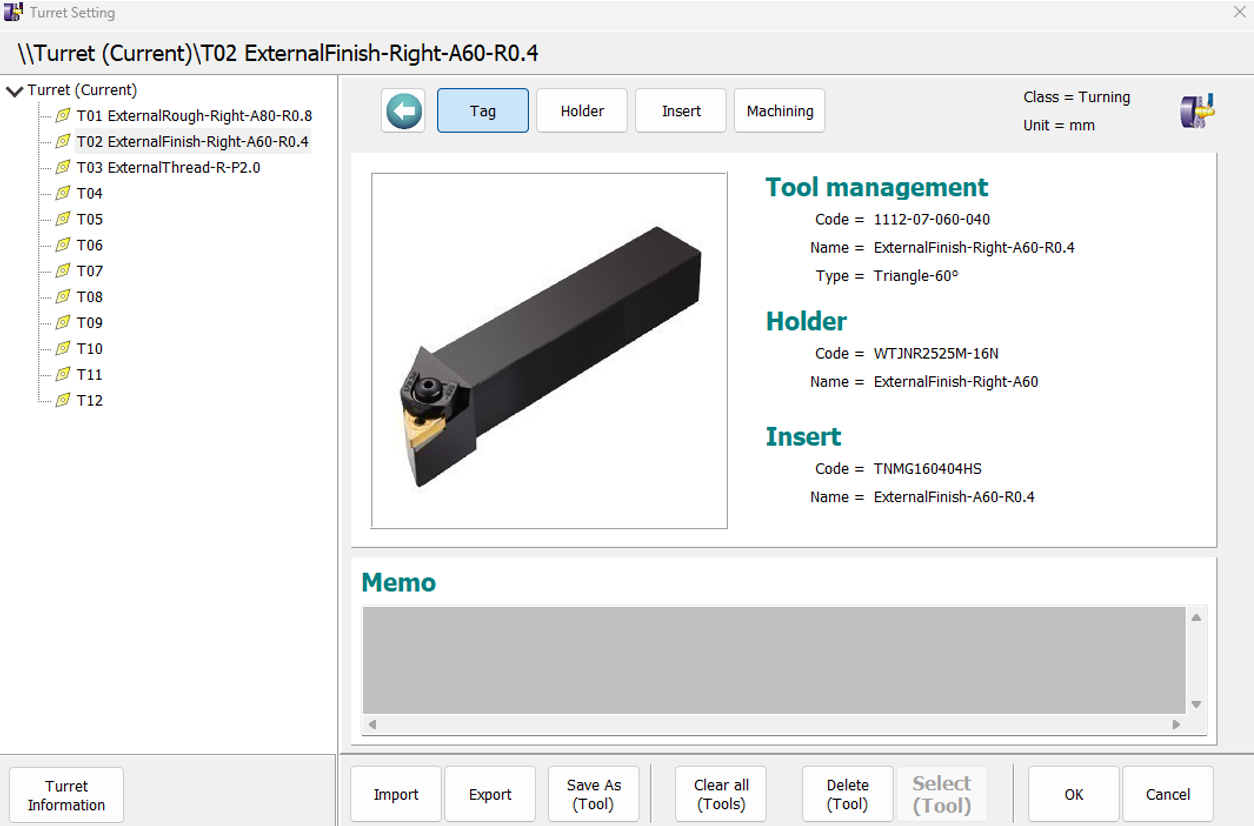

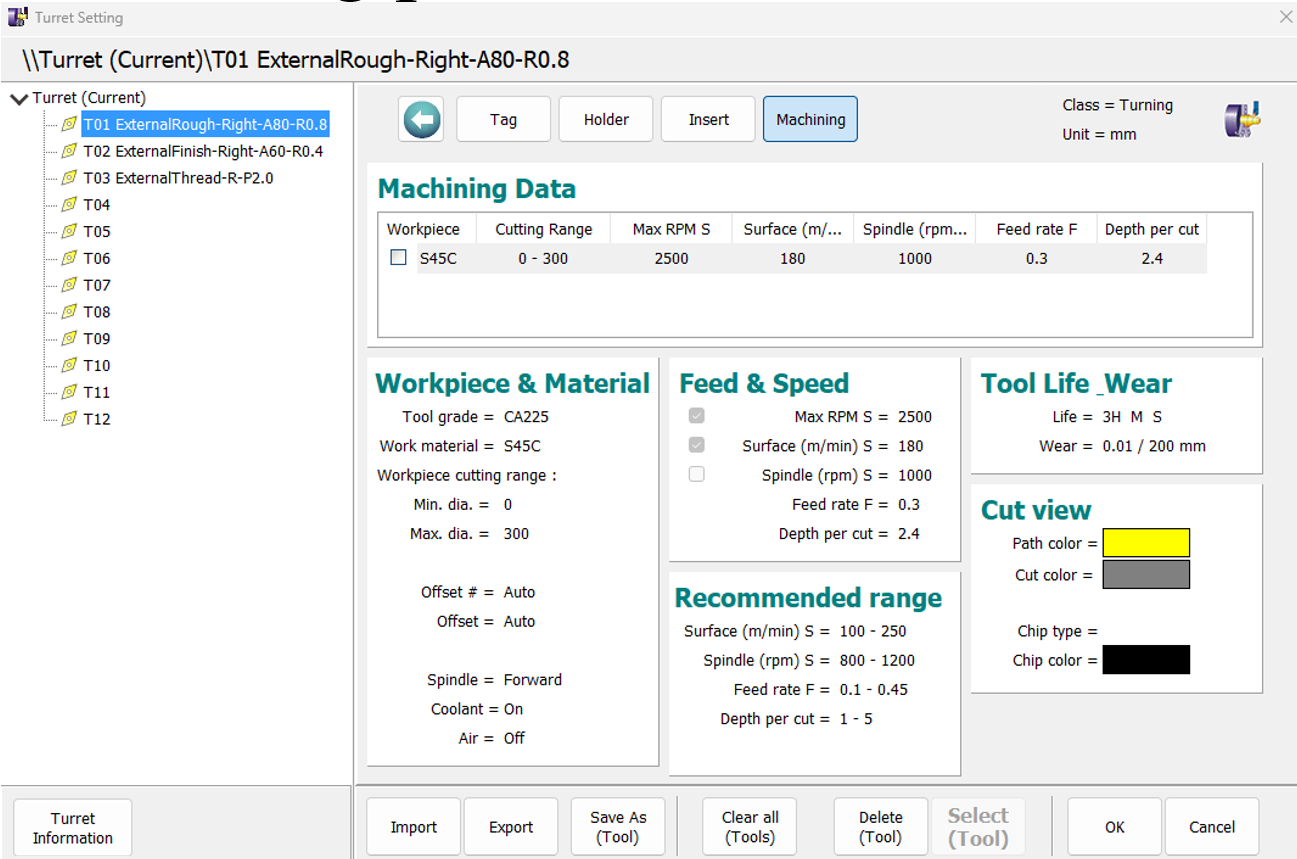

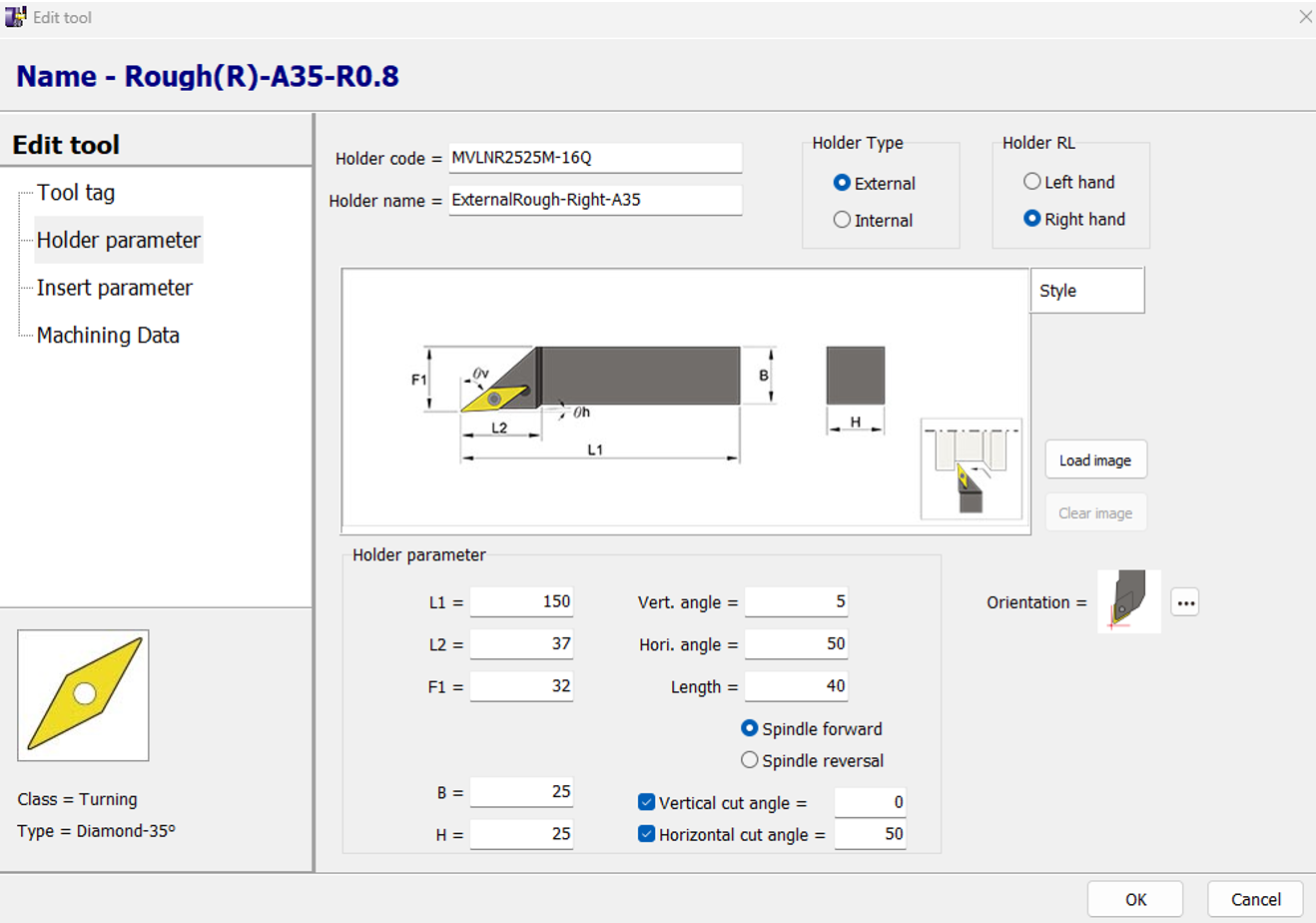

Tool library with 1300 + commonly used tools in industry.

Users don't need to spend time creating tools from the basic.

Tag

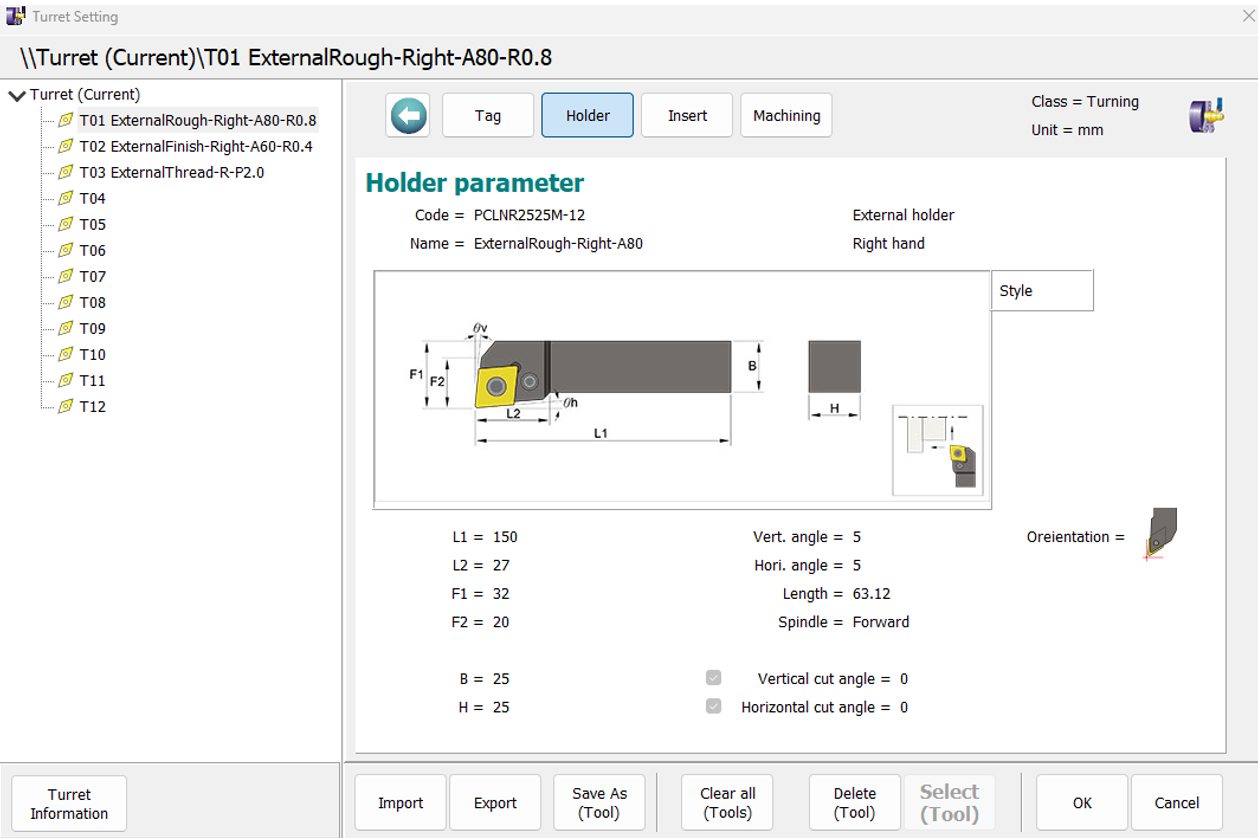

Holder parameter

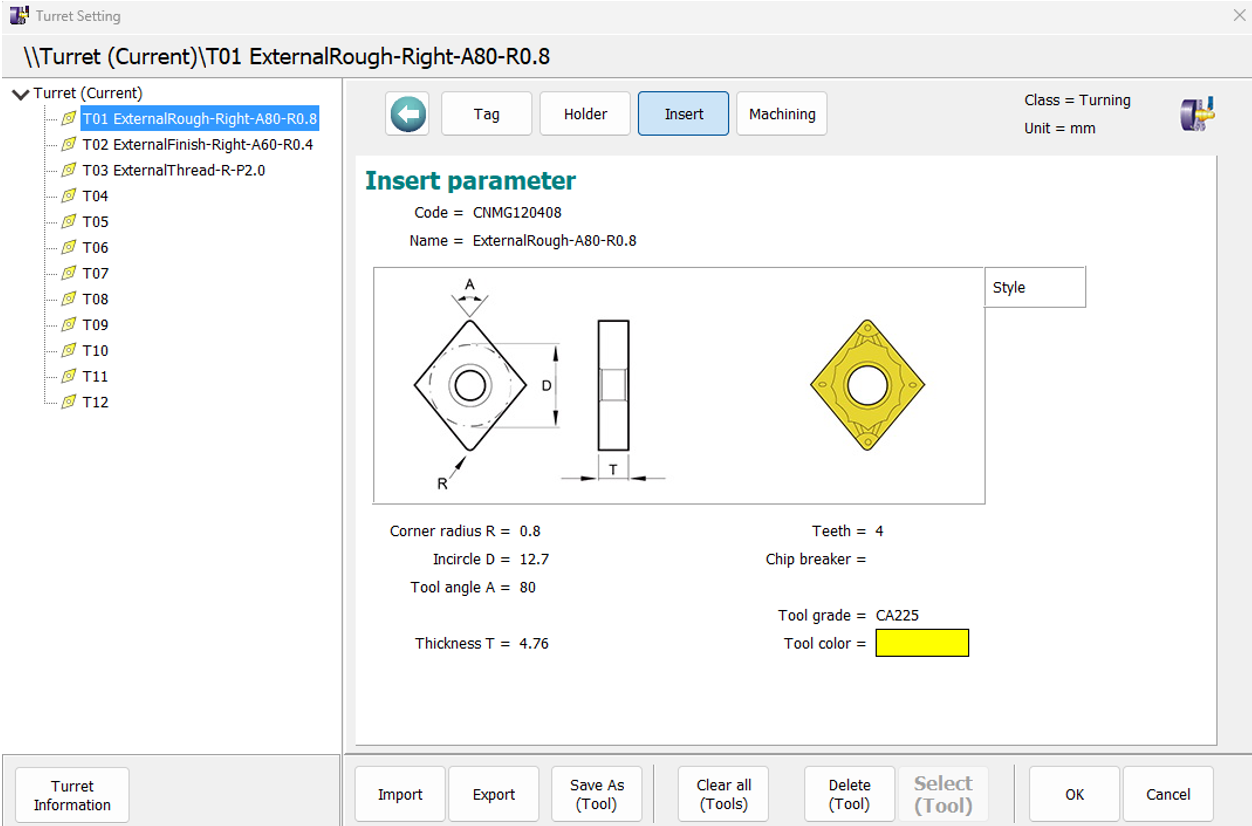

Insert parameter

machining parameter

Editing tool parameter: add, modify, delete.

Feature 8

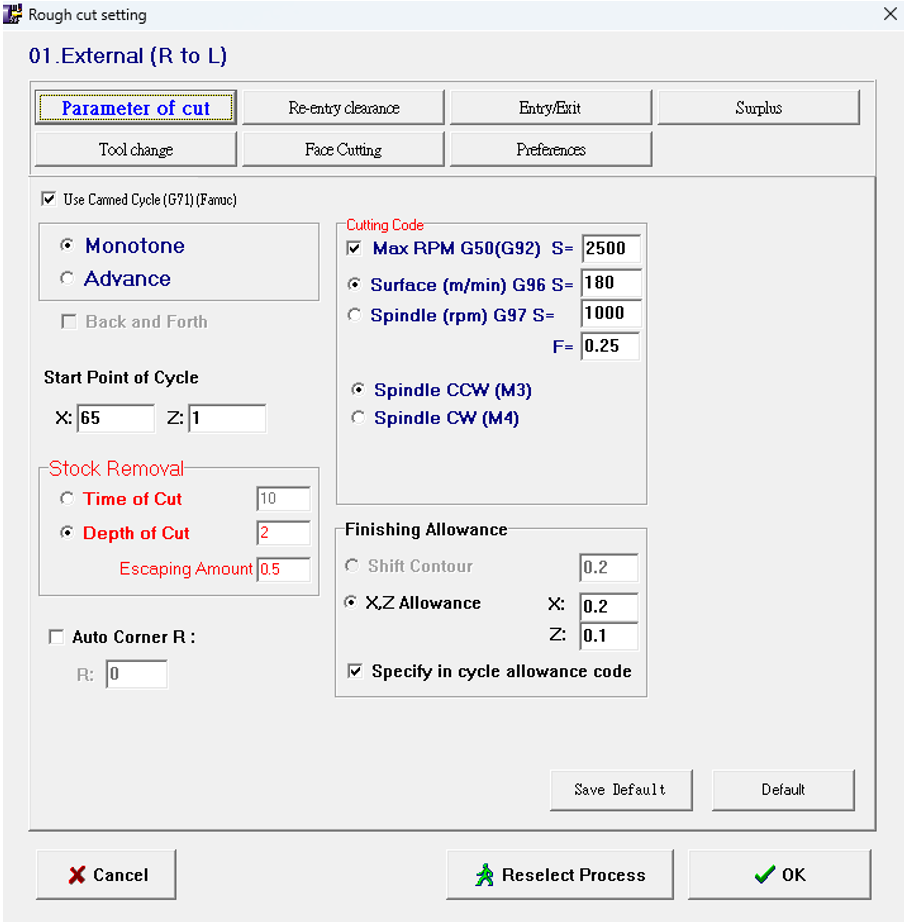

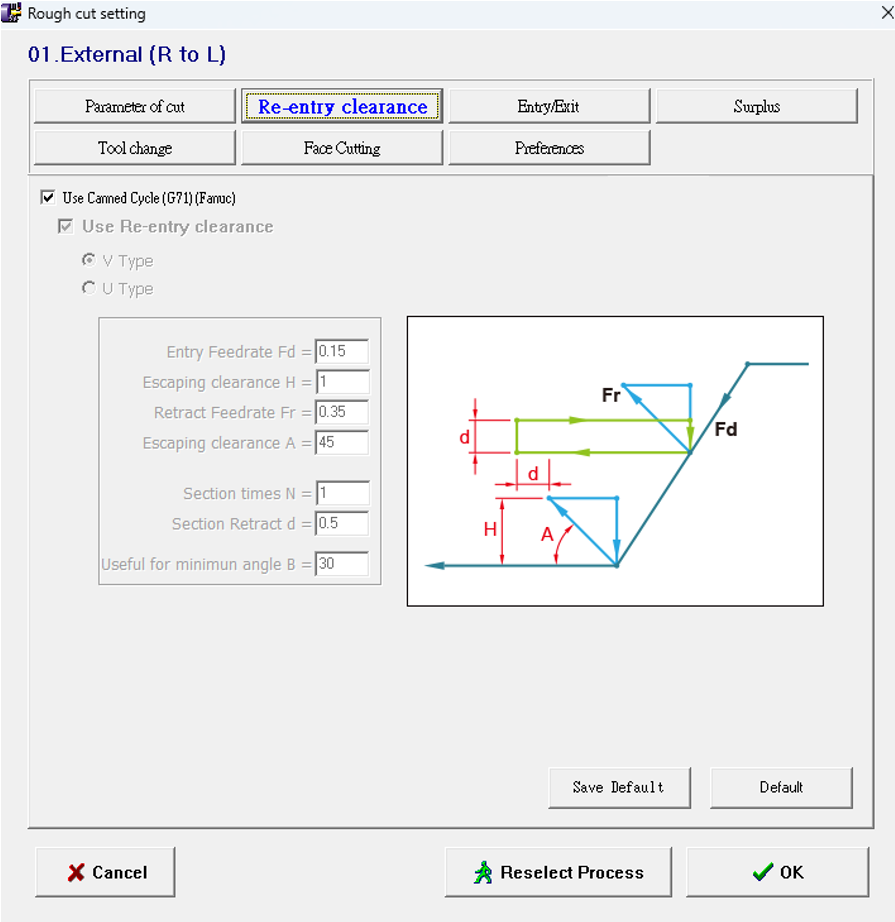

Processing parameter settings and cutting cycle are optional for users. Meet the requirement of different customers.

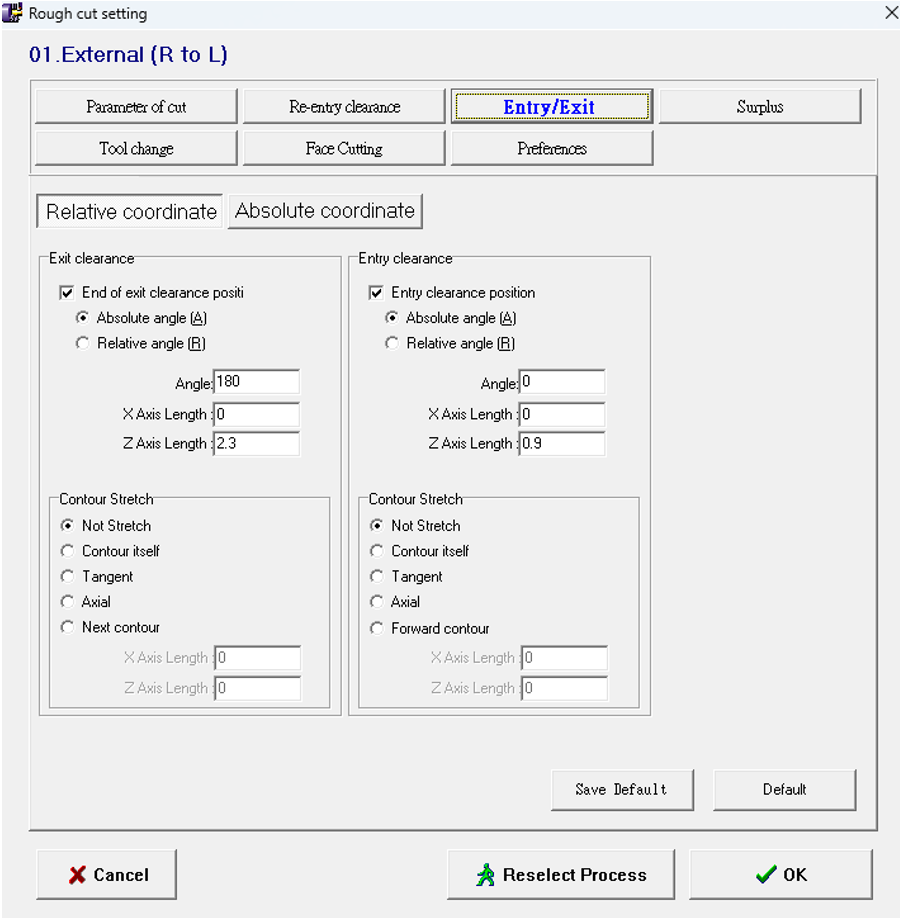

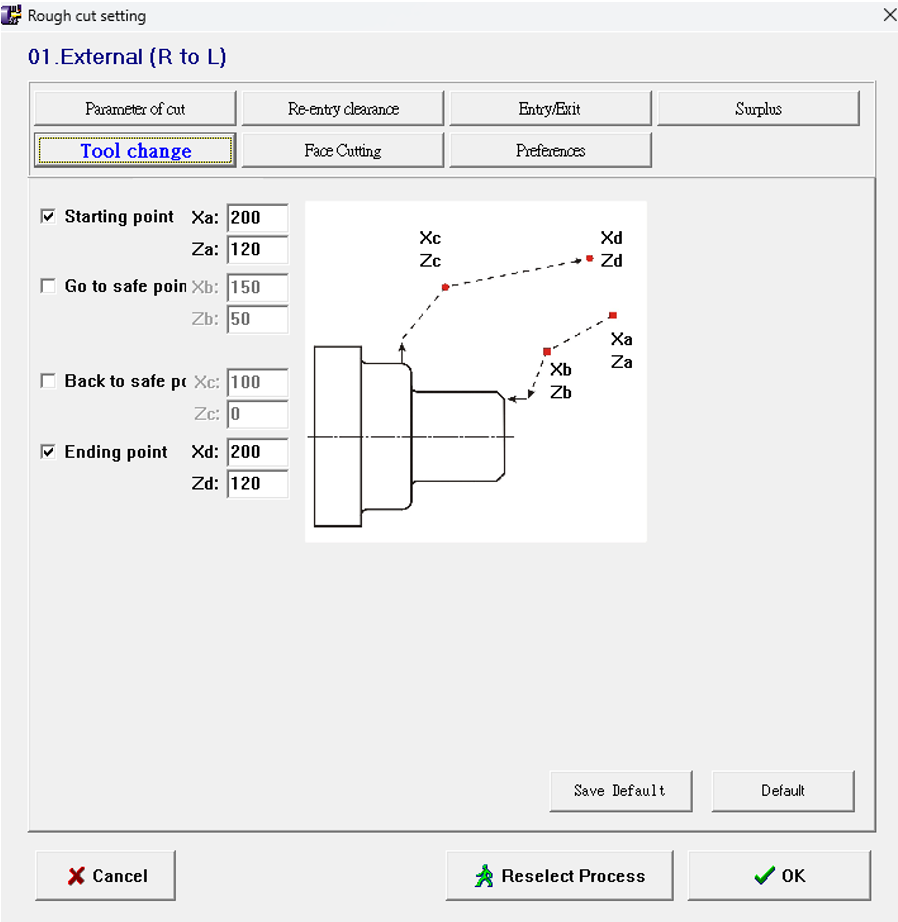

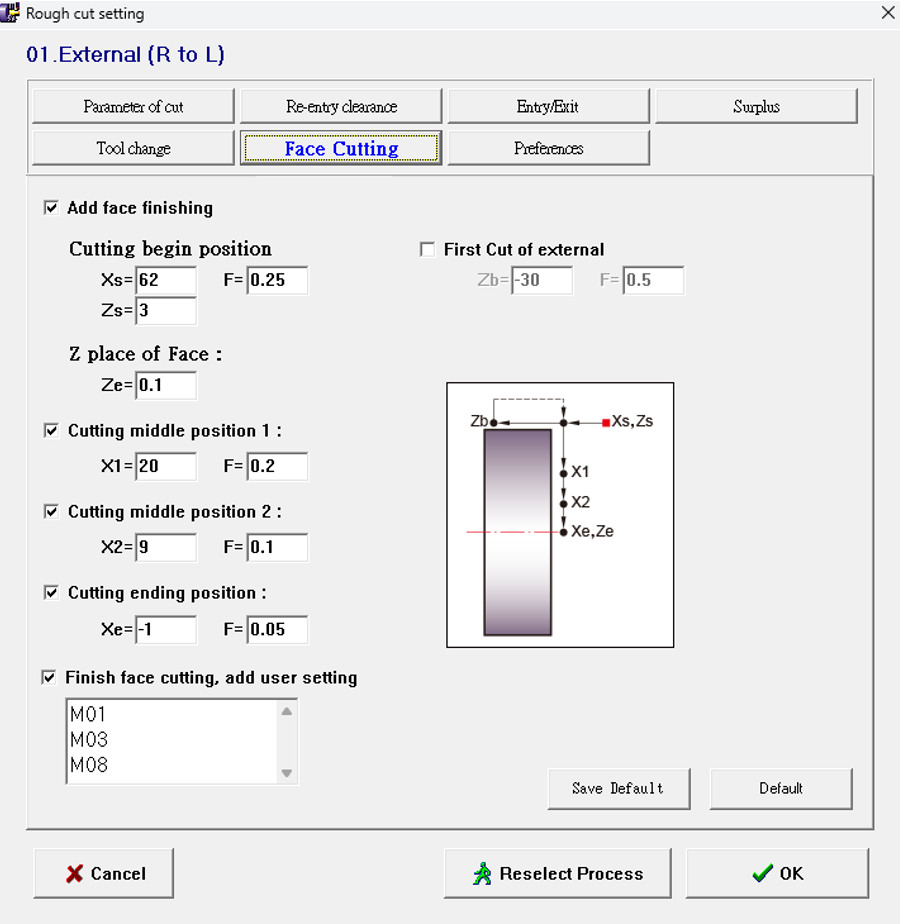

Ex: External Rough cutting

Parameter of cut: using cutting cycle or not, automatic corner R

Re-entry clearance, Entry / Exit, Surplus: adjustment of removing the chips

tool change, face cutting, preference: adjustment of tool change and face cutting

Parameter of cut

Re-entry clearance

Entry/Exit

Tool change

Face cutting

Feature 9

In the setting step, it shows the toolpath of the process.

N1 rough cutting toolpath

N2 finish cutting toolpath

N3 threading toolpath

FrankCAM Turning | User-friendly CADCAM Software | Post NC codes easily |

文章區塊