All

CNC Training and Skill Development

Five Ladder CNC Training Courses

Ladder 1 CNC Basic Knowledge and Manual Programming

Ladder 2 CNC Controller Operation

Ladder 3 CADCAM Software

Ladder 4 CNC Ability Checking

CNC machining software

replyBack

RenAn Information Heidenhain Controller Simulation Software

VM Heidenhain TNC640 5 Axis

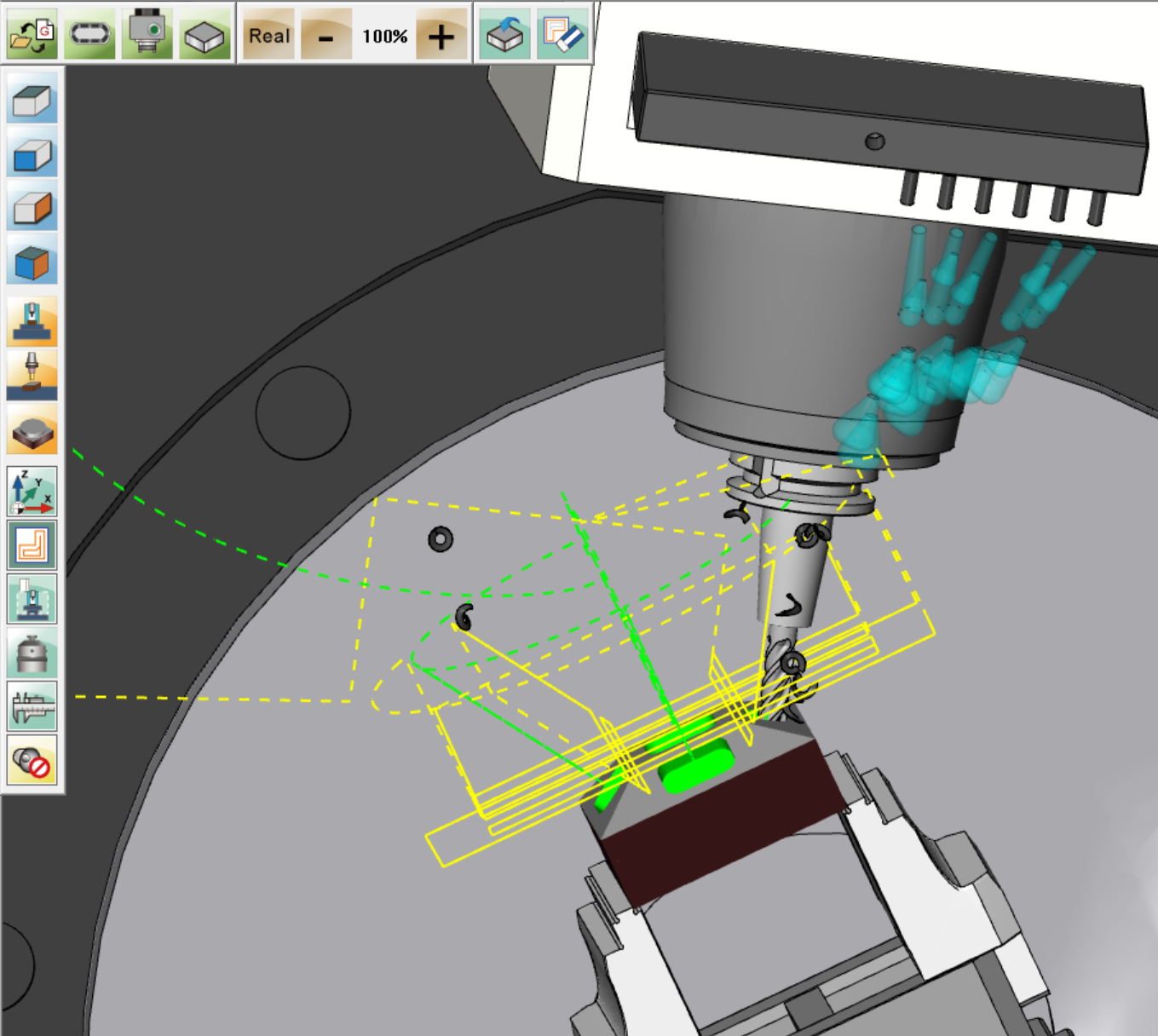

Realistic CNC Controller Function Panel, Modularized Machine Operation Panel, and CNC Machine Simulation. Excellent simulation software for CNC controller recognition and practicing tool offset.

RenAn Information Heidenhain Controller Simulation Software – The Ideal Partner for Advanced CNC Operations

As the core system in high-end CNC milling machines, the Heidenhain controller is widely used in precision manufacturing industries globally, especially in aerospace, medical equipment, and mold-making sectors where high precision is critical. To help companies improve production efficiency and enhance operator training, RenAn Information has developed a professional Heidenhain Controller Simulation Software, allowing users to safely and efficiently practice real-world operations in a simulated environment.

Key Features of the Heidenhain Controller

1. Precision Motion Control:

The Heidenhain controller offers industry-leading precision motion control, capable of executing highly accurate trajectory planning in complex 5-axis machining, making it ideal for producing intricate and high-precision components.

2. 5-Axis Simultaneous Machining:

With multi-axis simultaneous control, the system significantly reduces the need for workpiece repositioning and adjustments, thus improving machining efficiency and product quality.

3. Dynamic Compensation Technology:

The built-in dynamic compensation feature automatically corrects for machine thermal expansion and environmental changes, ensuring consistent high-precision performance throughout the machining process.

4. Intuitive User Interface:

The controller provides a powerful graphical interface, allowing operators to easily edit programs and manage machining operations quickly, making it suitable for users of all skill levels.

Core Benefits of RenAn's Heidenhain Simulation Software

RenAn Information's Heidenhain Controller Simulation Software is designed to help companies and learners fully unlock the potential of Heidenhain controllers. Whether practicing machine operations or previewing cutting paths, this software significantly enhances production accuracy and operational safety.

1. Highly Realistic Simulated Environment:

The simulation software replicates the actual operating environment, allowing users to simulate the entire process from tool setup to machining. This helps operators become familiar with complex procedures in a risk-free virtual setting.

2. Preview Cutting Paths to Reduce Risks:

Operators can preview cutting paths before starting the machining process, preventing potential errors and improving the pass rate of workpieces, thereby reducing scrap production.

3. Hands-on Practice and Skill Training:

The software serves as an ideal training tool for both beginners and experienced operators. It allows new users to safely learn machine operations and helps skilled technicians further refine their techniques without worrying about equipment wear or production downtime.

4. Cost Savings and Equipment Longevity:

By practicing in a simulated environment, companies can significantly reduce the frequency of actual machine use, lowering equipment wear and extending the lifespan of costly machinery, resulting in substantial cost savings.

An Ideal Solution for Senior Management and Professional Operators

For senior executives looking to enhance CNC machining efficiency and operators or trainees aiming to master advanced CNC technologies, RenAn Information's Heidenhain Controller Simulation Software is an indispensable tool. This software not only strengthens technical training but also ensures stability in production processes, helping businesses stand out in a competitive market.

Power On and do the machining

Switching to different view angle

Empower your operators and technical team with RenAn Information's Heidenhain Simulation Software to boost productivity and achieve exceptional machining quality and efficiency.

文章區塊