All

CNC Training and Skill Development

Five Ladder CNC Training Courses

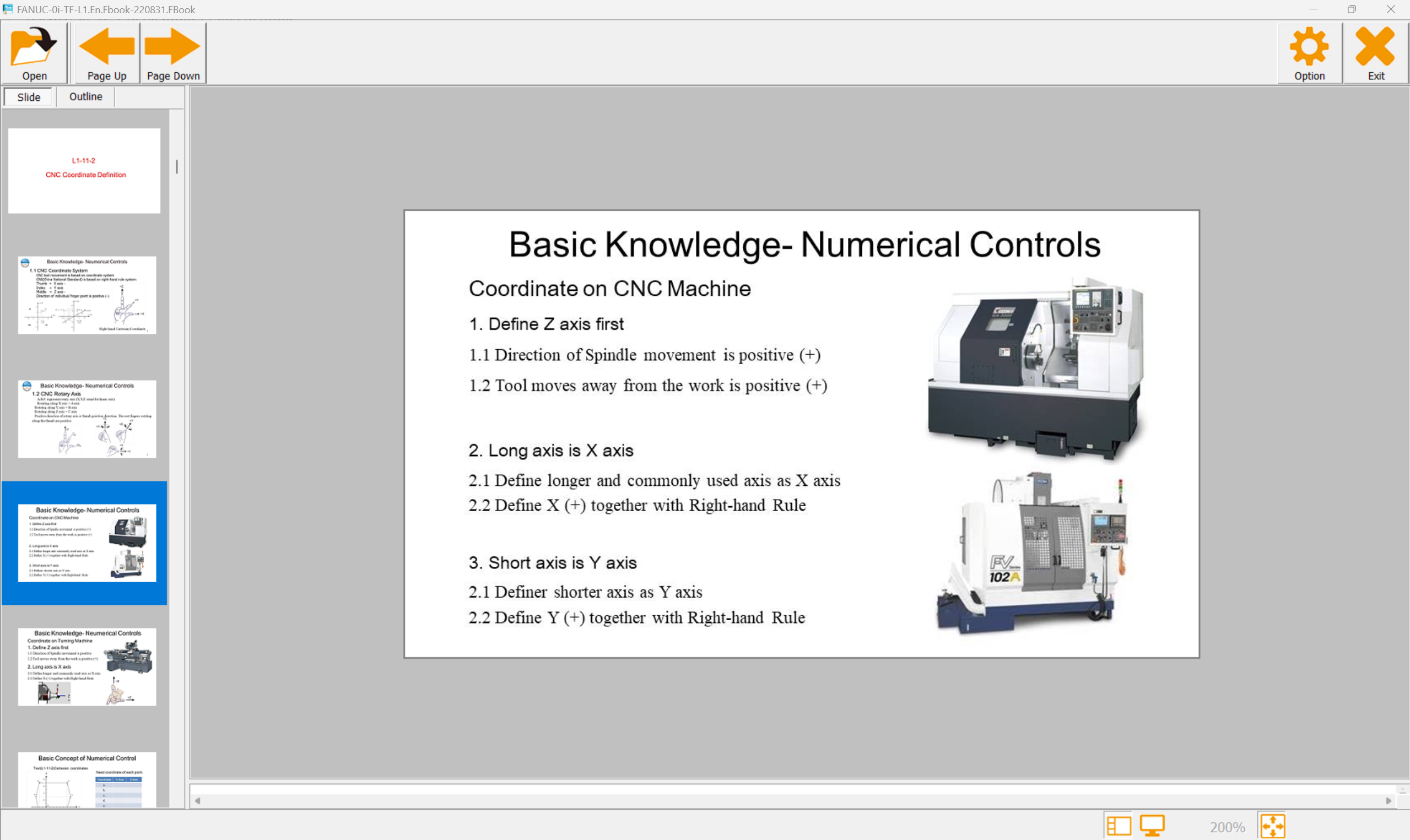

Ladder 1 CNC Basic Knowledge and Manual Programming

Ladder 2 CNC Controller Operation

Ladder 3 CADCAM Software

Ladder 4 CNC Ability Checking

CNC machining software

replyBack

CNC Testing & Assessment

Digital teaching and assessment systems can solve the problem of a small number of machines and practice hours, and improve learning efficiency for teachers and students.

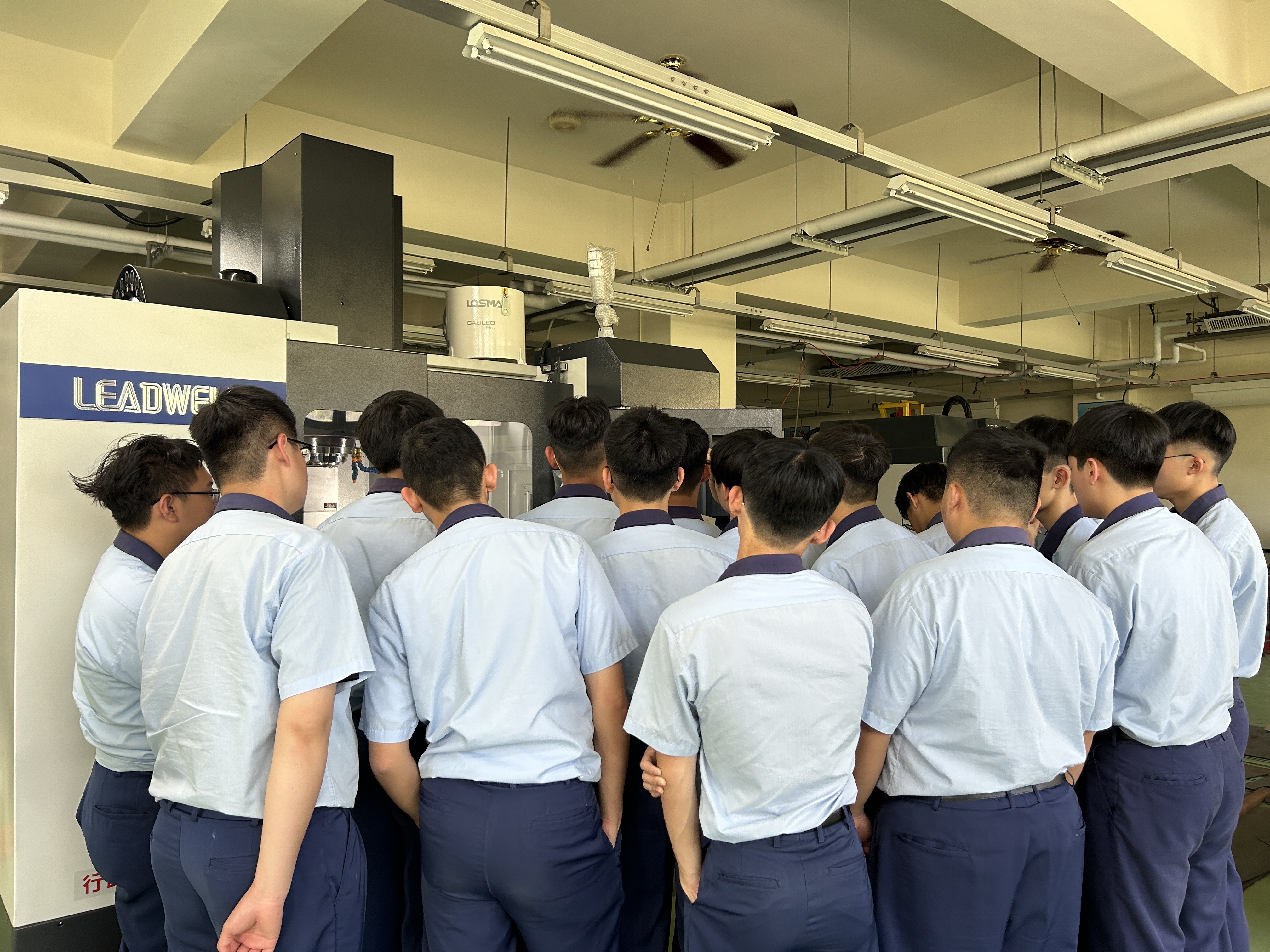

In today's mechanical education environment, machine resources often cannot meet student needs, which is a challenge faced by many schools. For example, a school's mechanical department has 30 students, but only 2 machines provide operating practice. This imbalance between teachers, students and equipment is extremely common. Since each student has limited opportunities to operate the machine, it is difficult for them to actually meet the requirements for proficiency in machine operation. In addition, in traditional teaching, in order to ensure the safety of students' operations, teachers need to accompany and grade the whole process, which consumes a lot of time and has certain risks.

In order to solve these problems, RenAn Information has launched innovative CNC teaching resources and smart assessment systems. This system not only provides a safe and realistic CNC operating environment, but also allows for diverse operating exercises and instant evaluation. By simulating the real environment of the machine, students can practice operations independently without occupying the actual machine, which reduces the school's burden on equipment resources.

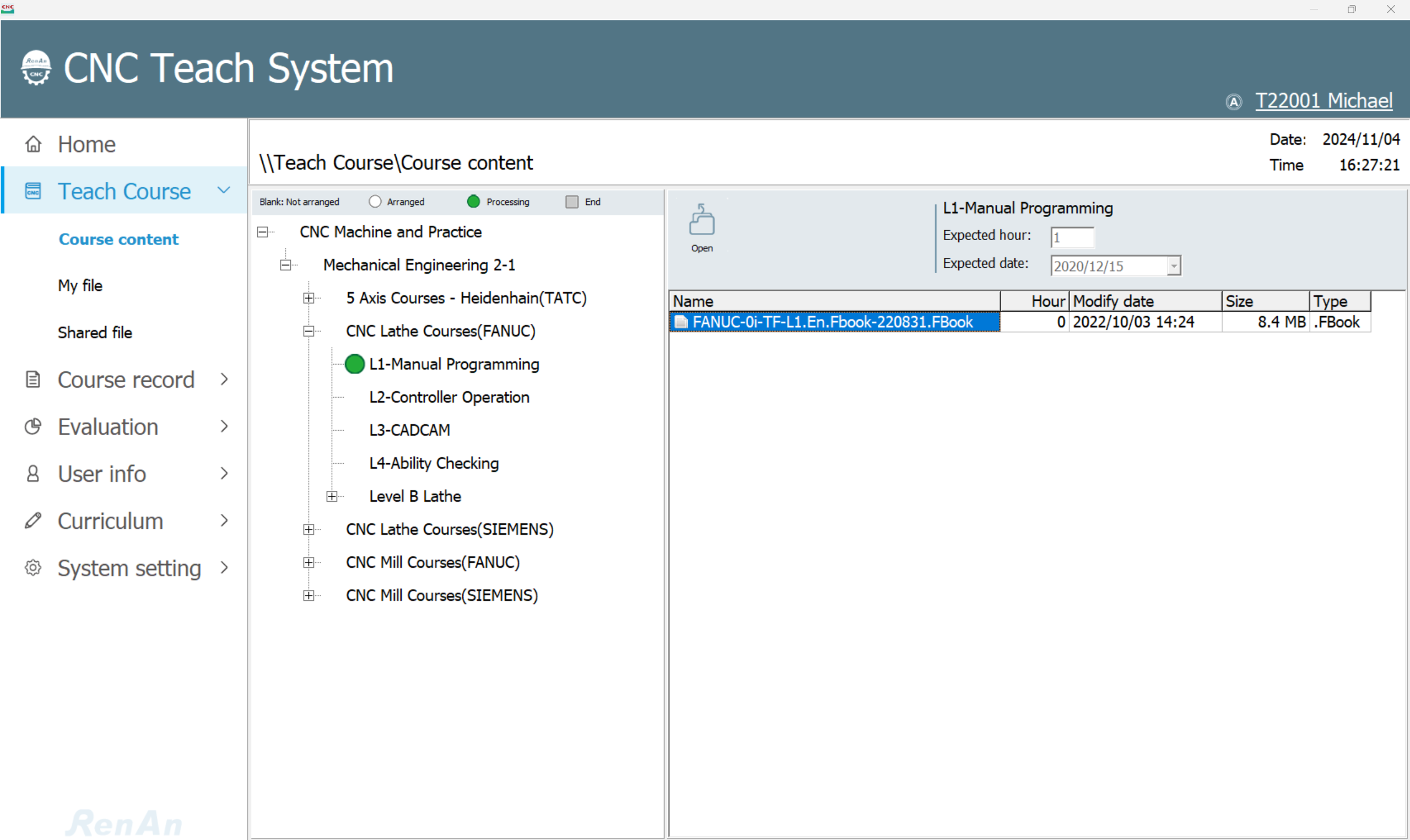

CNC teaching resources and smart assessment system

Fbook teaching materials and courseware

Teaching courses > Course content > CNC lathe courseware (Fanuc) > L1

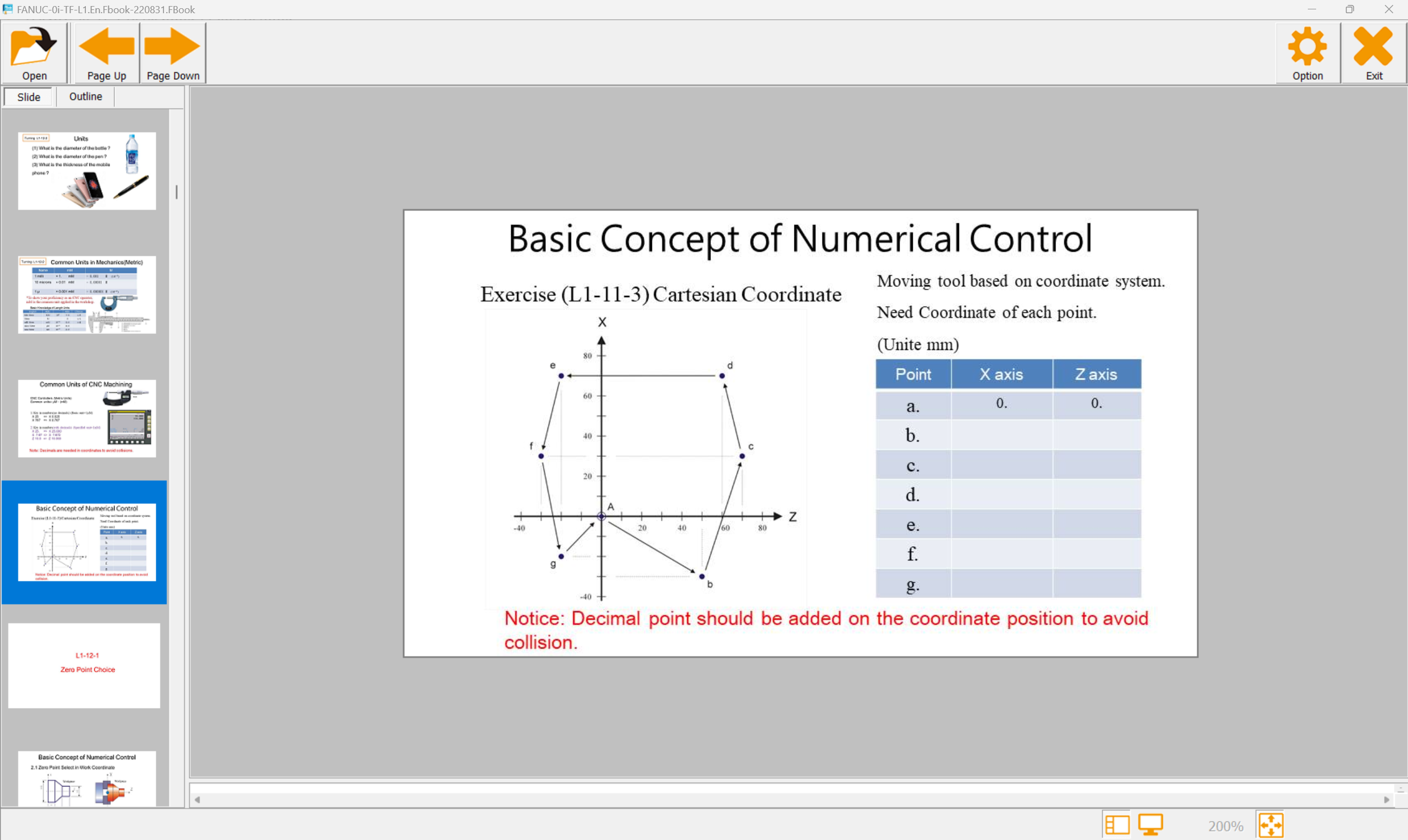

Basic concepts of numerical control

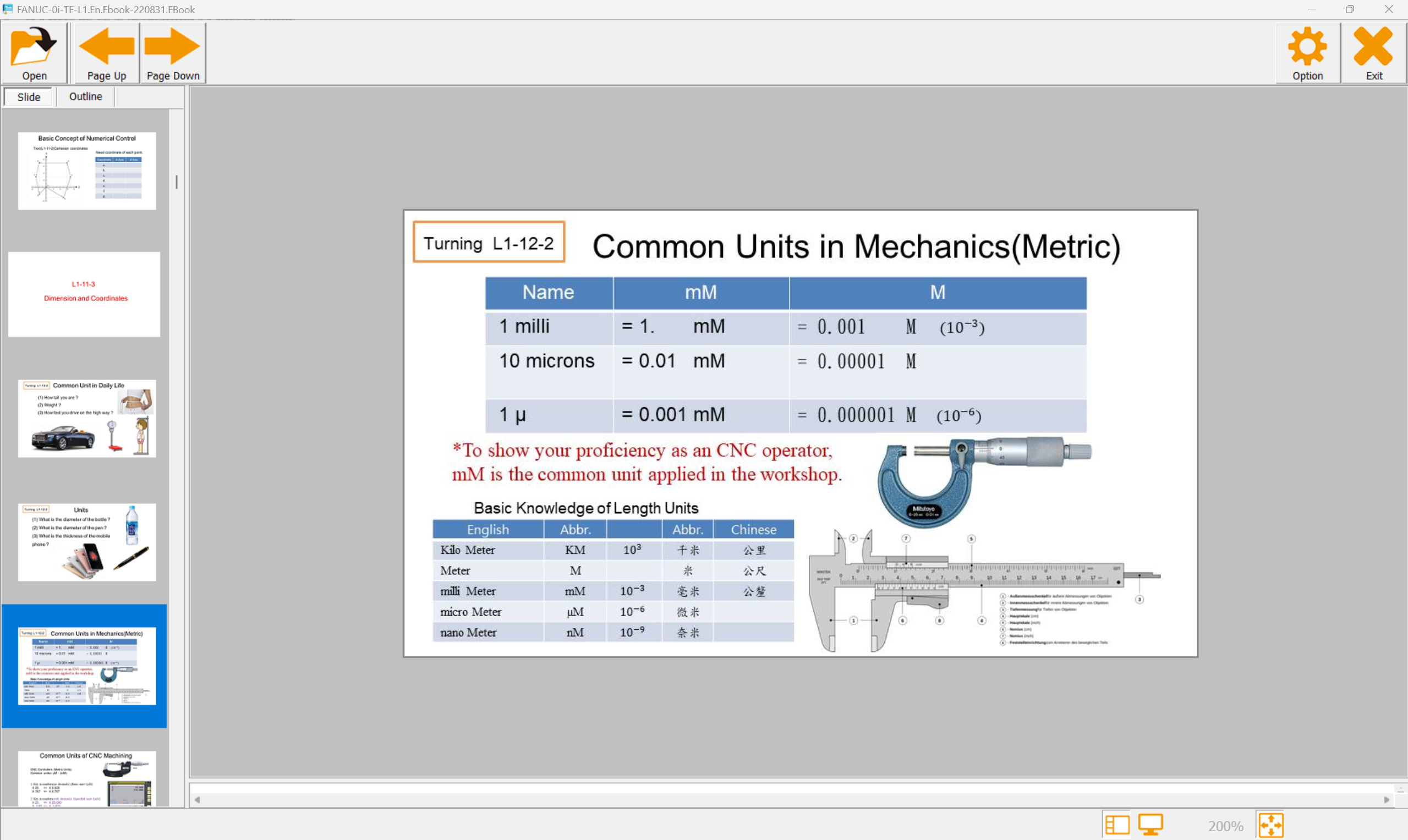

Commonly used units for machinery

unit exercises

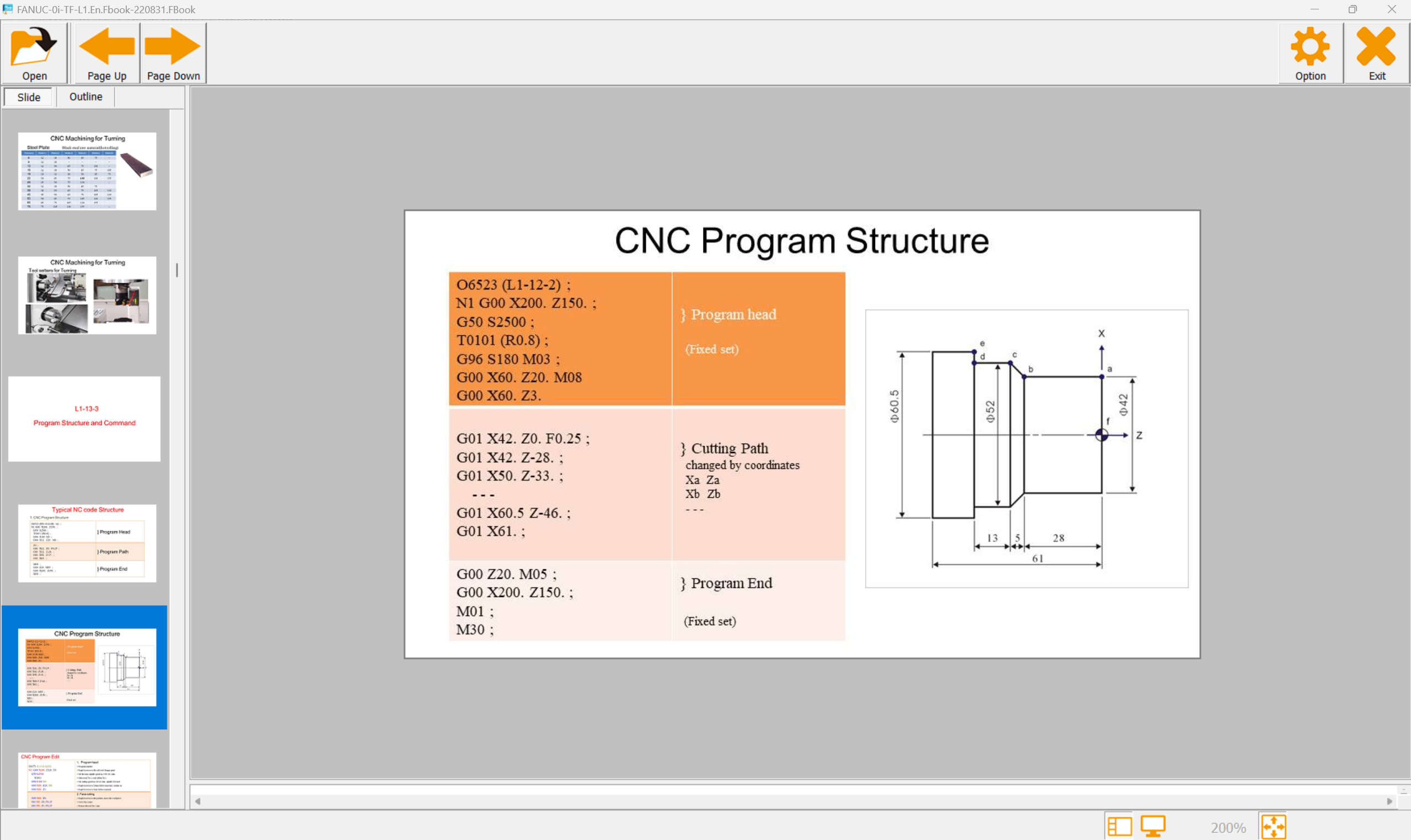

CNC program structure

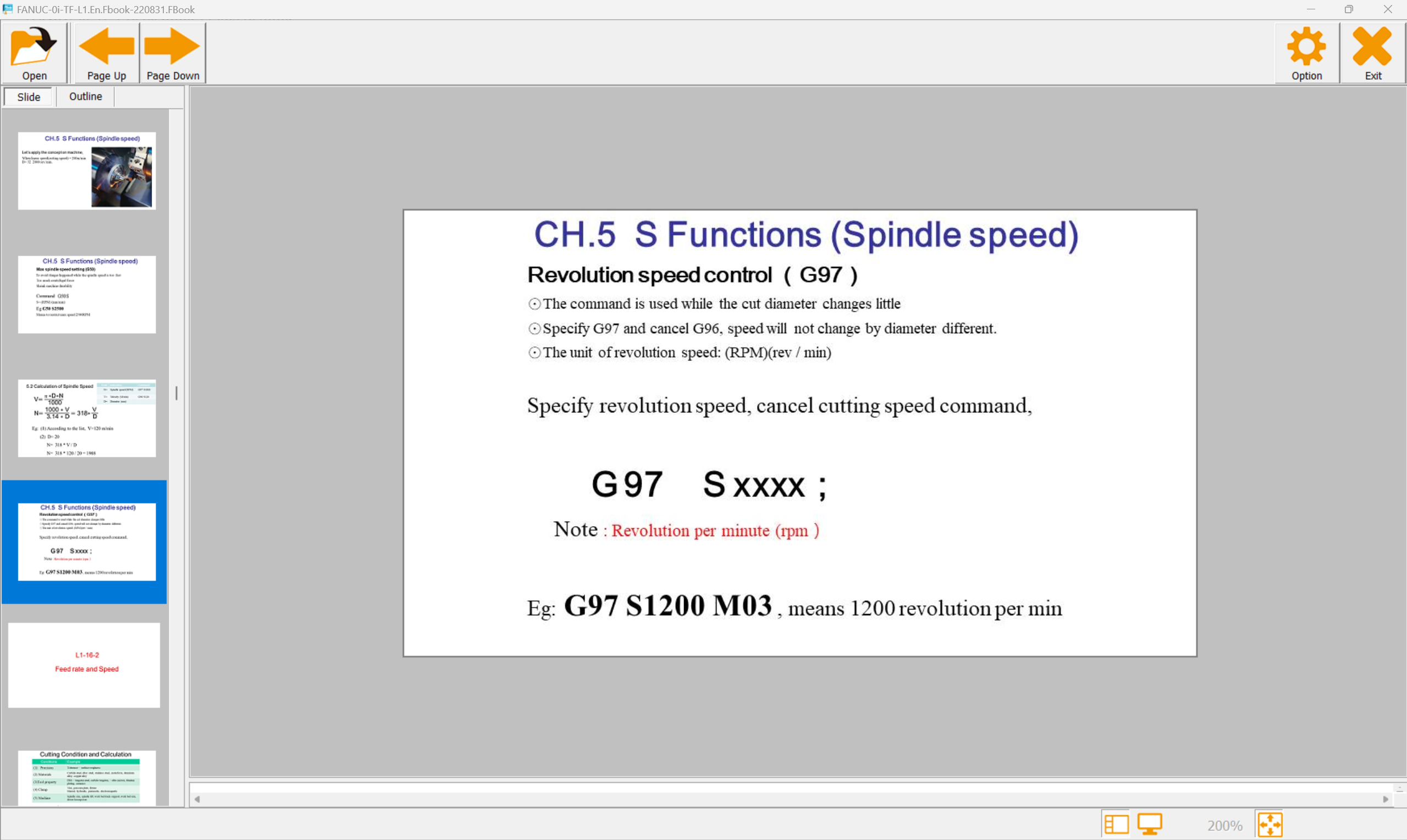

S function (spindle speed function)

CNC teaching resources and smart assessment system

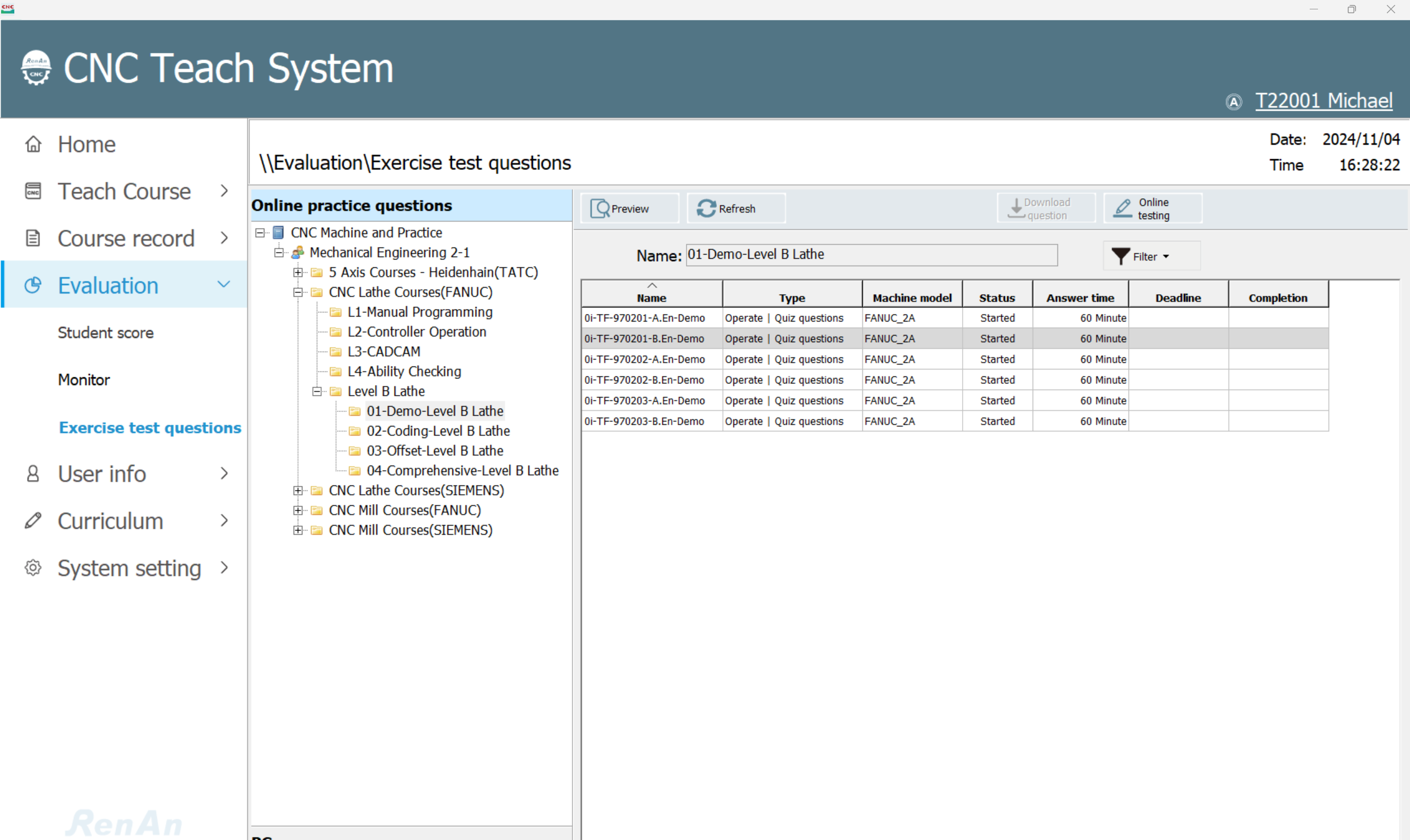

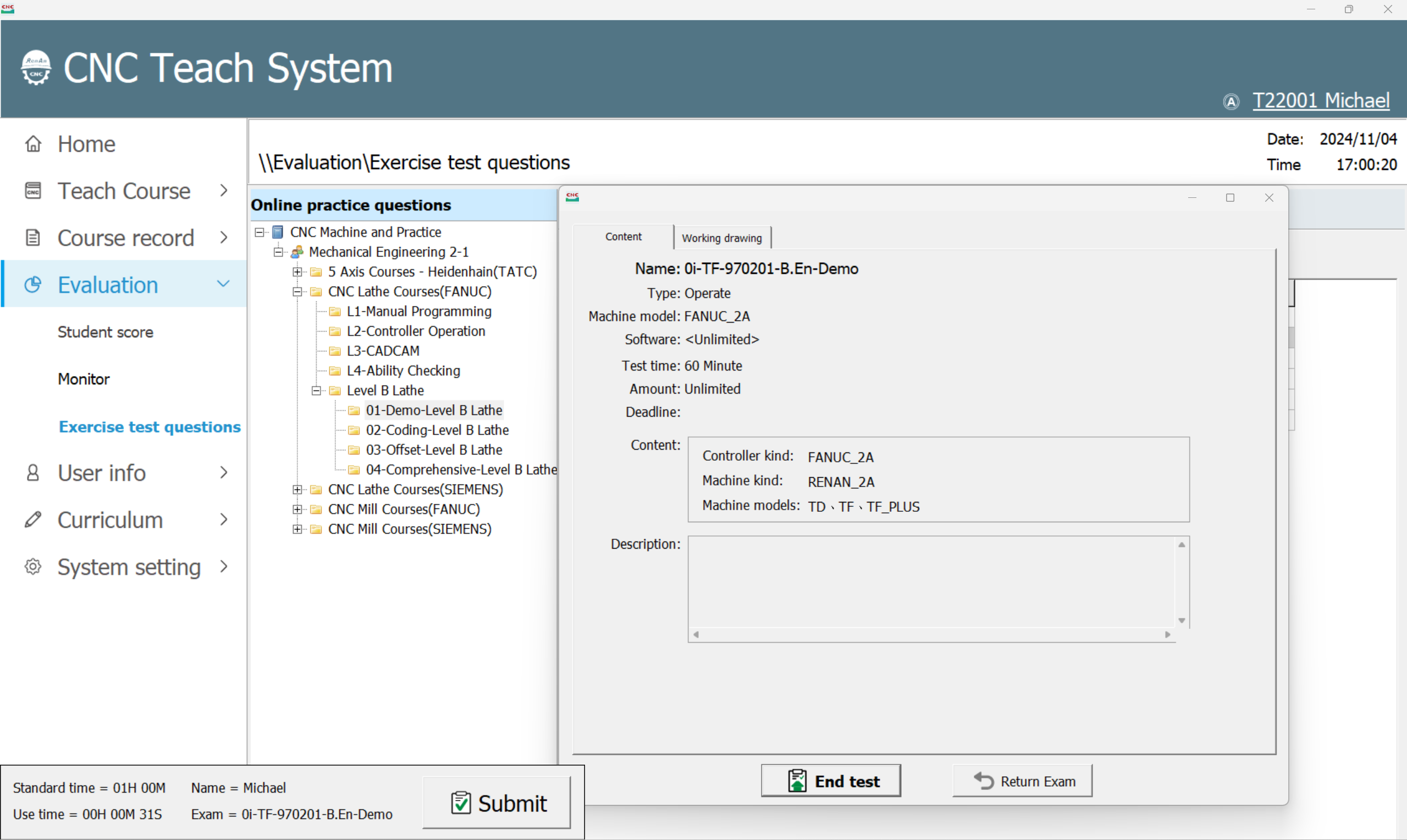

Smart assessment system

Assessment > Test Questions > Level B Lathe

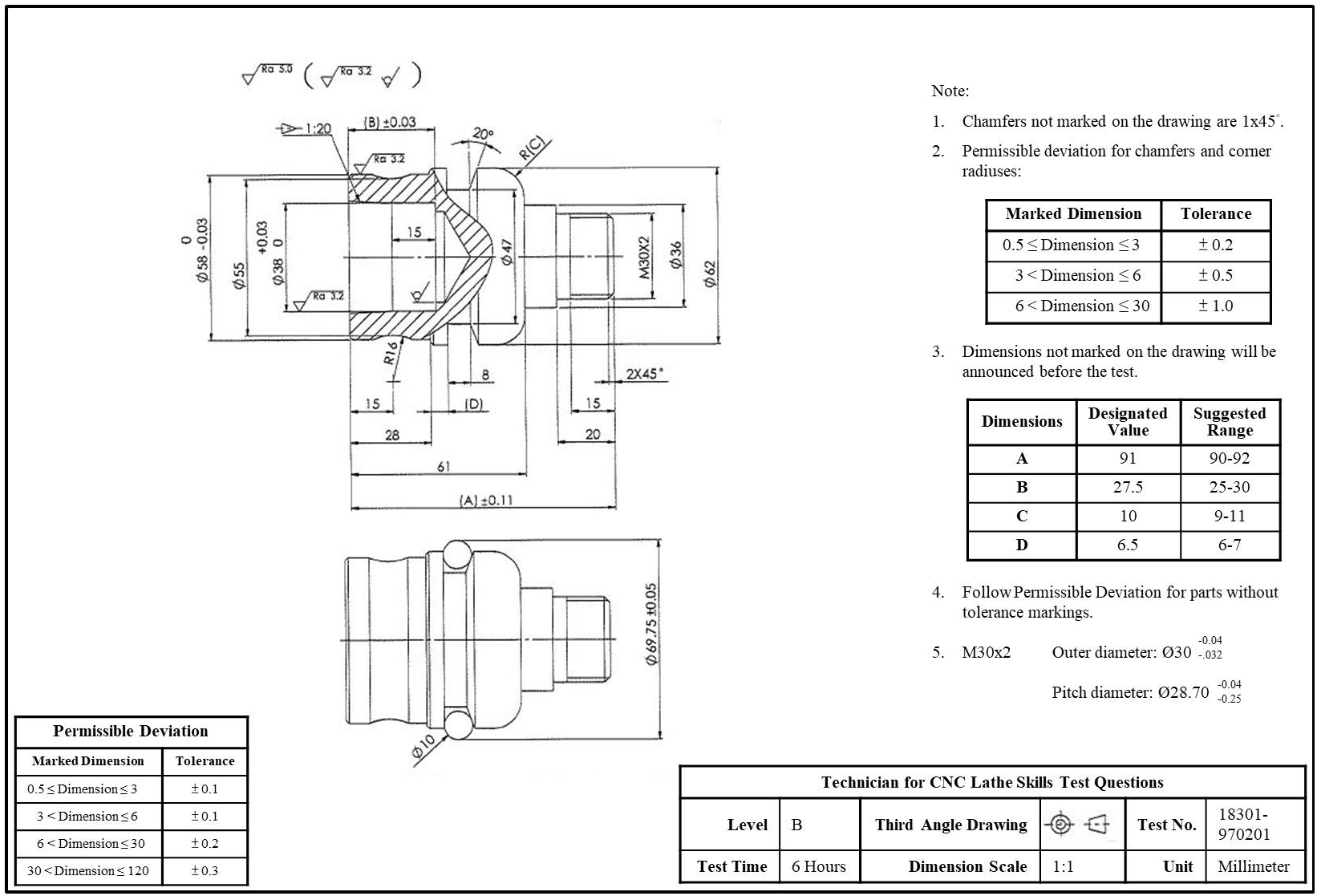

Lathe-CNC Lathe Item Technician Skills Certification Technique Test Questions

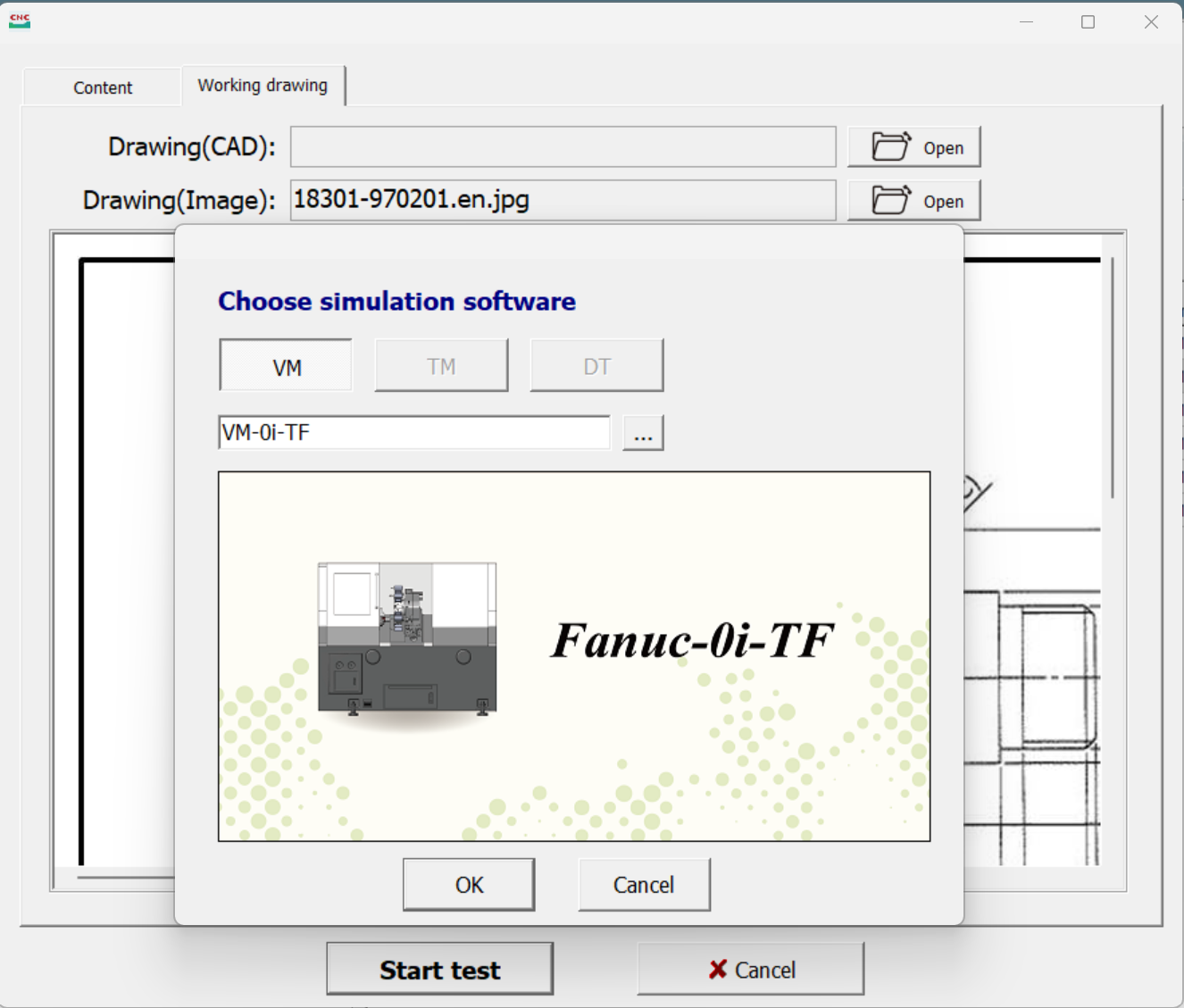

Select simulation software

Start the assessment

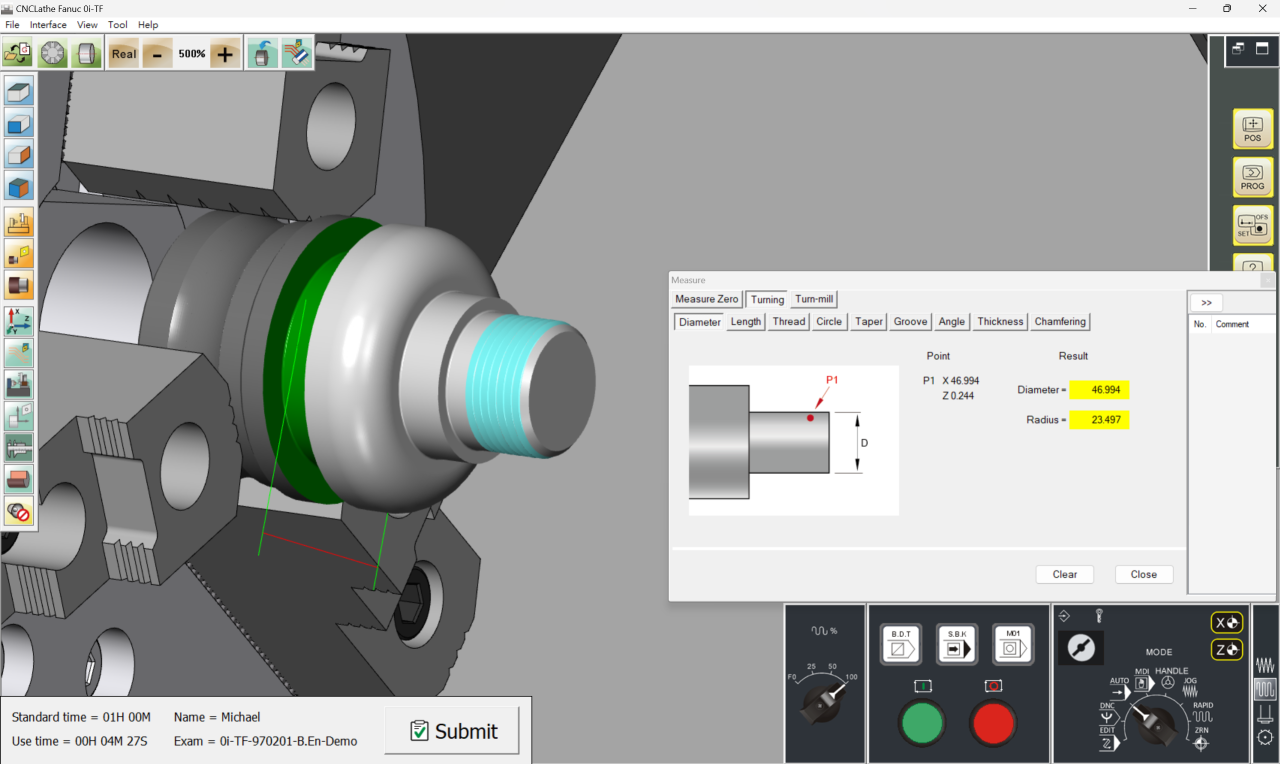

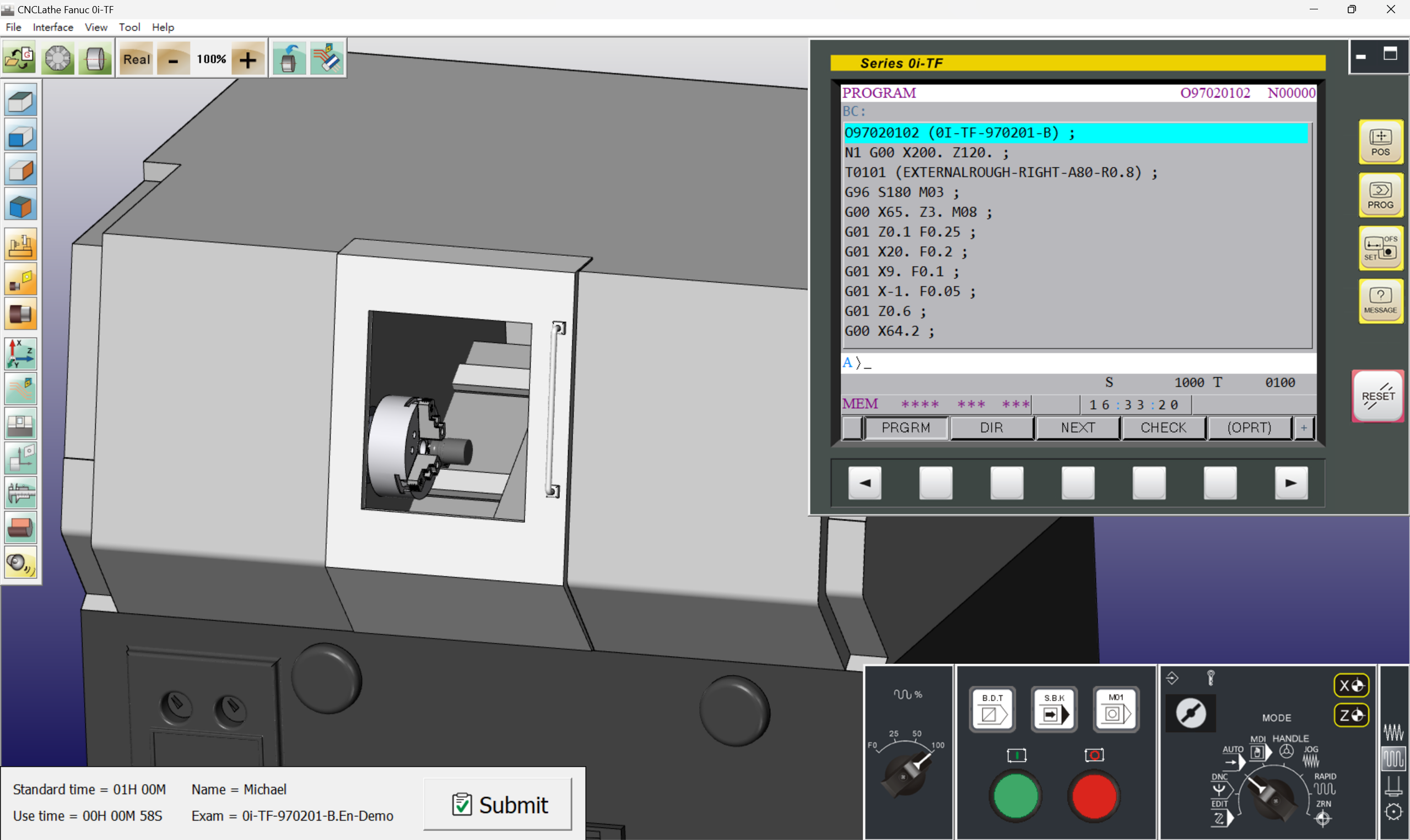

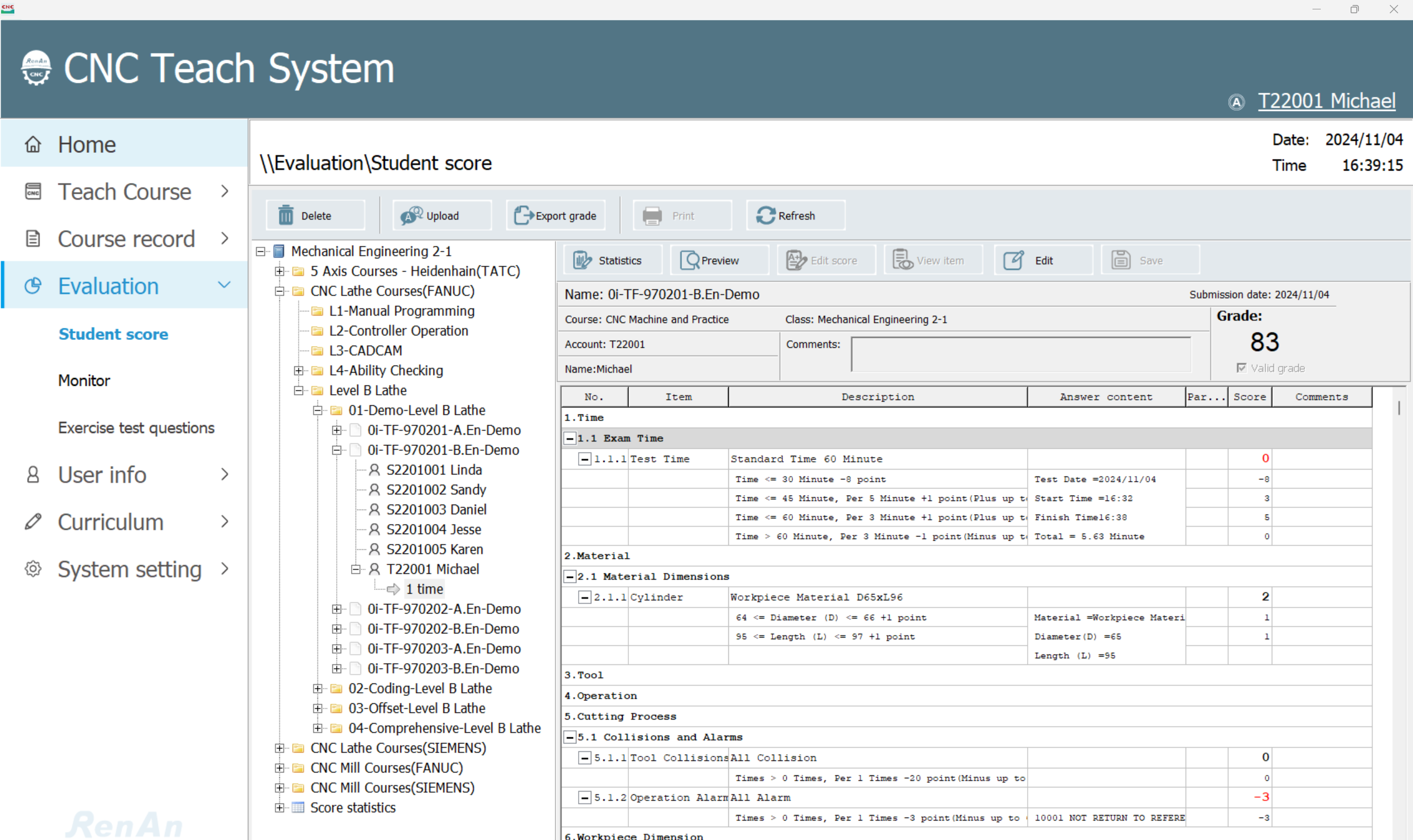

In the lower left corner, you can see the assessment standard time, accumulated time, candidate name, and test paper name.

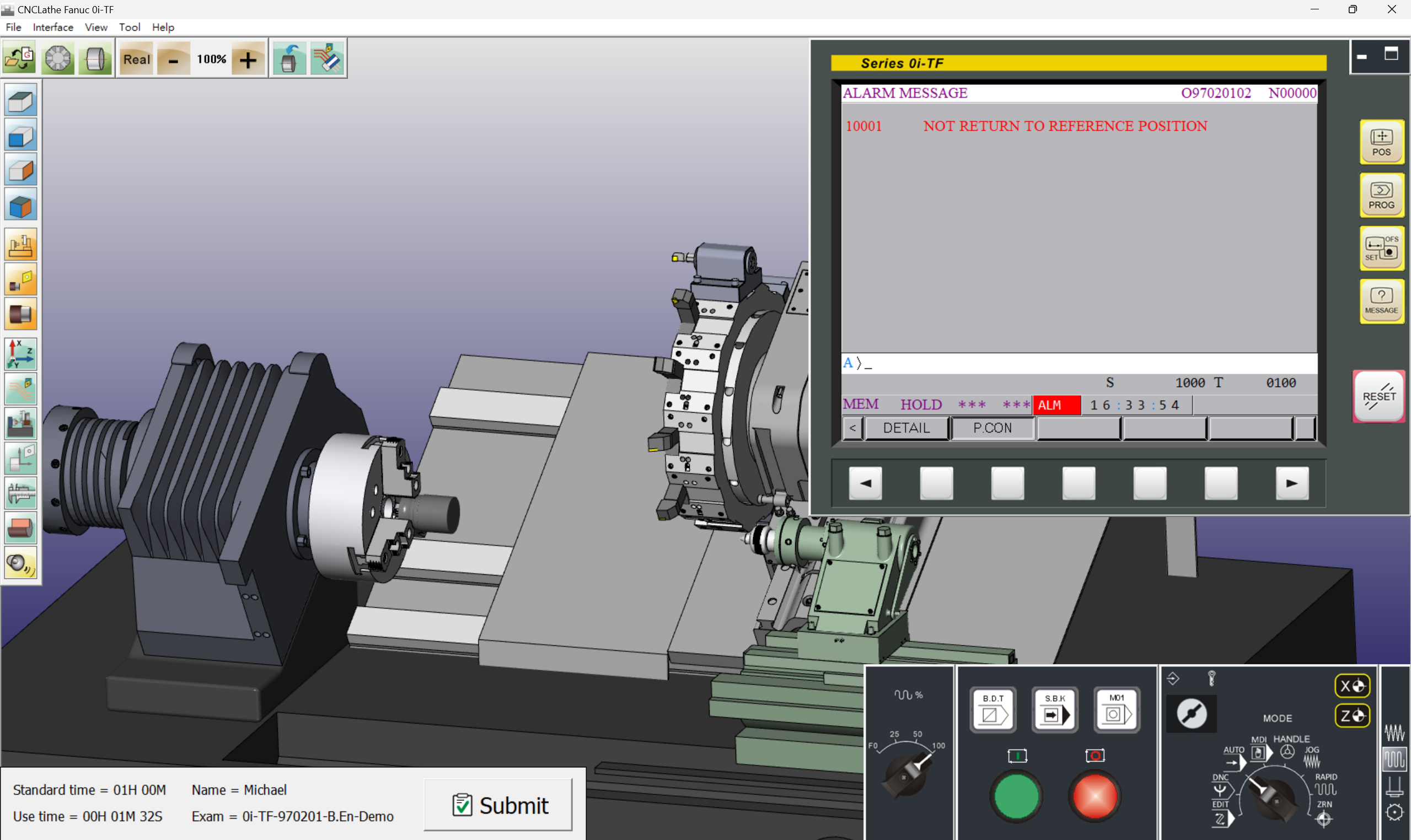

During the operation, if there is an alarm (for example: not return to the origin), the system will record it.

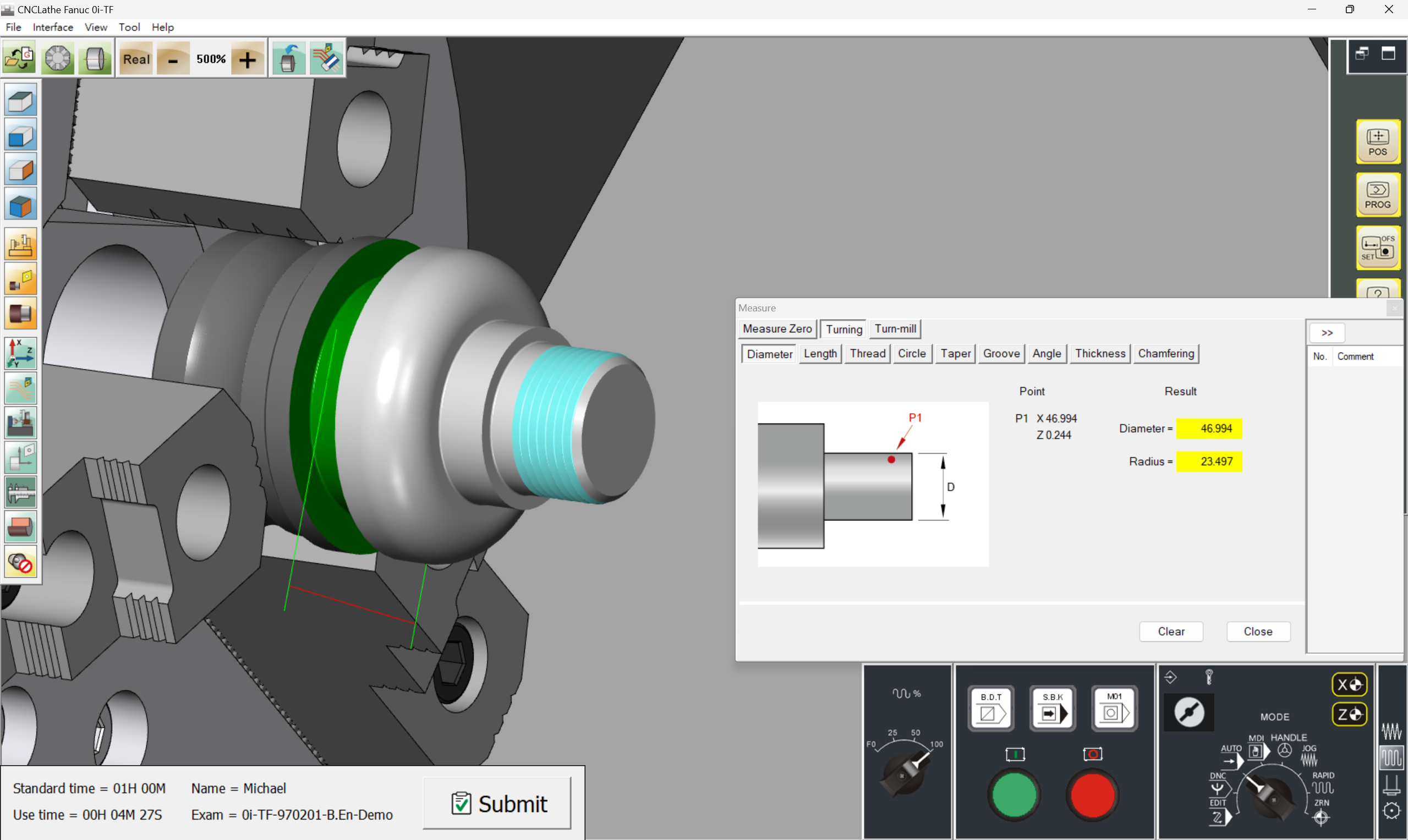

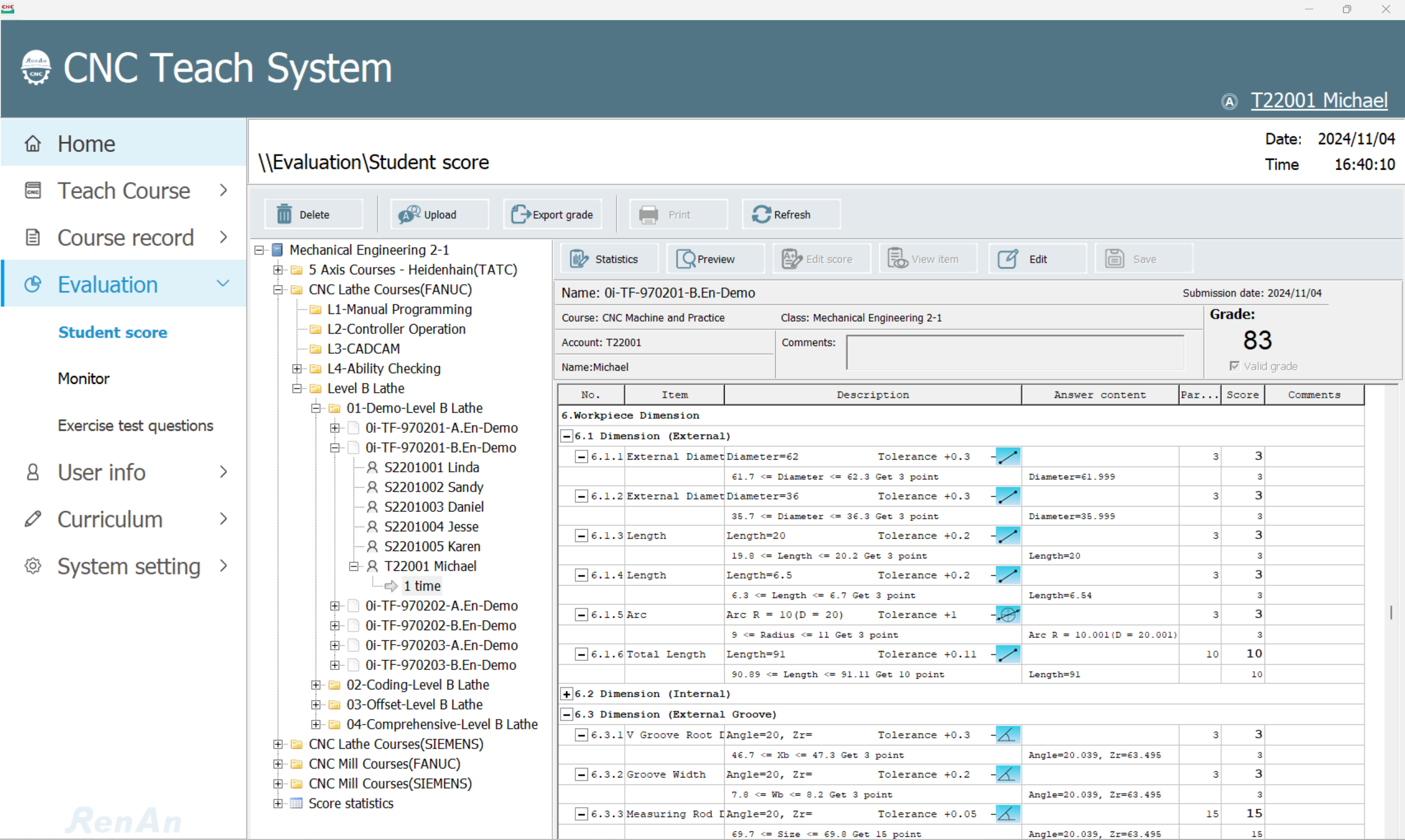

Dimensional Measurements > Diameter

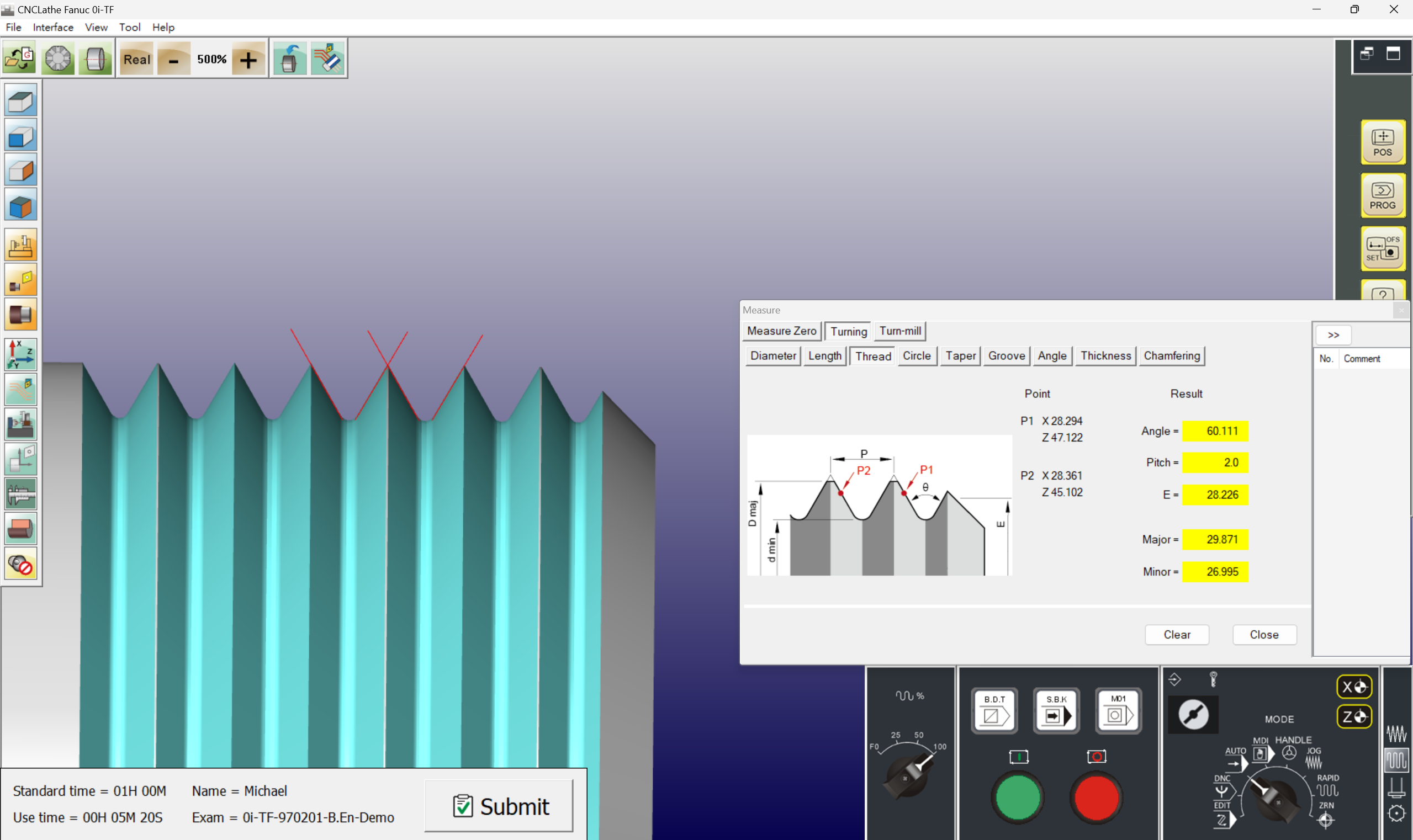

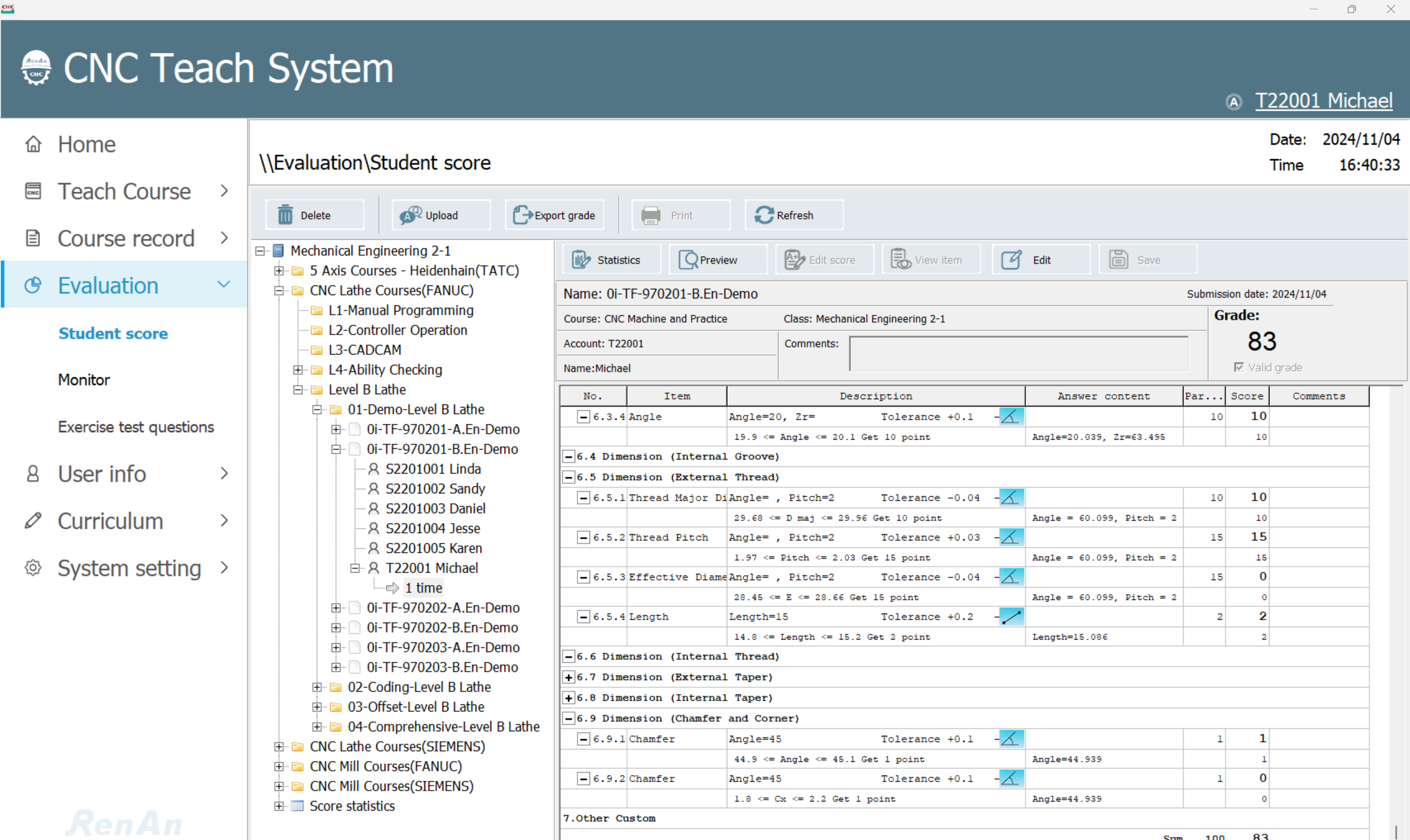

Dimensional Measurements > Threads

Submit > End test

Get the score immediately

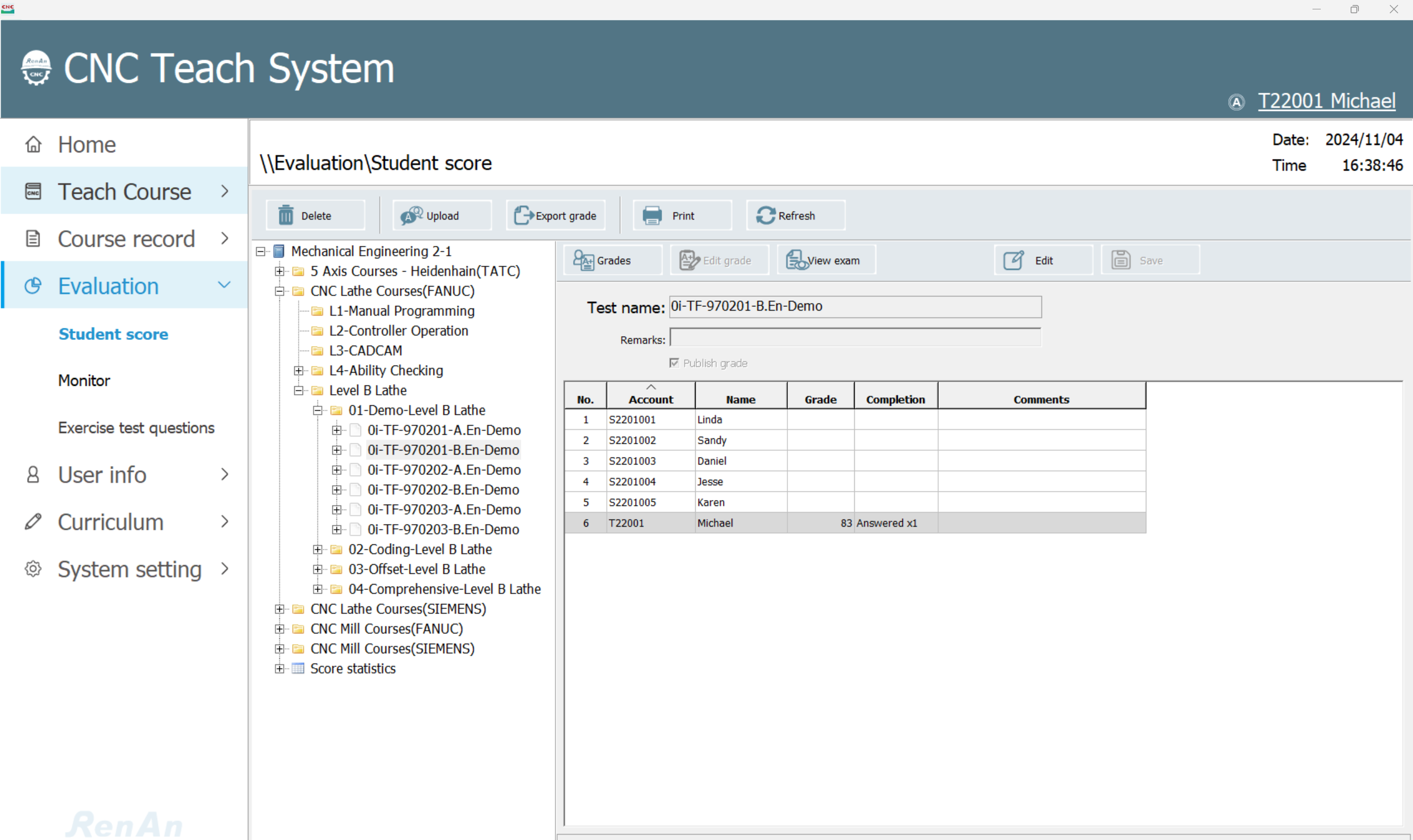

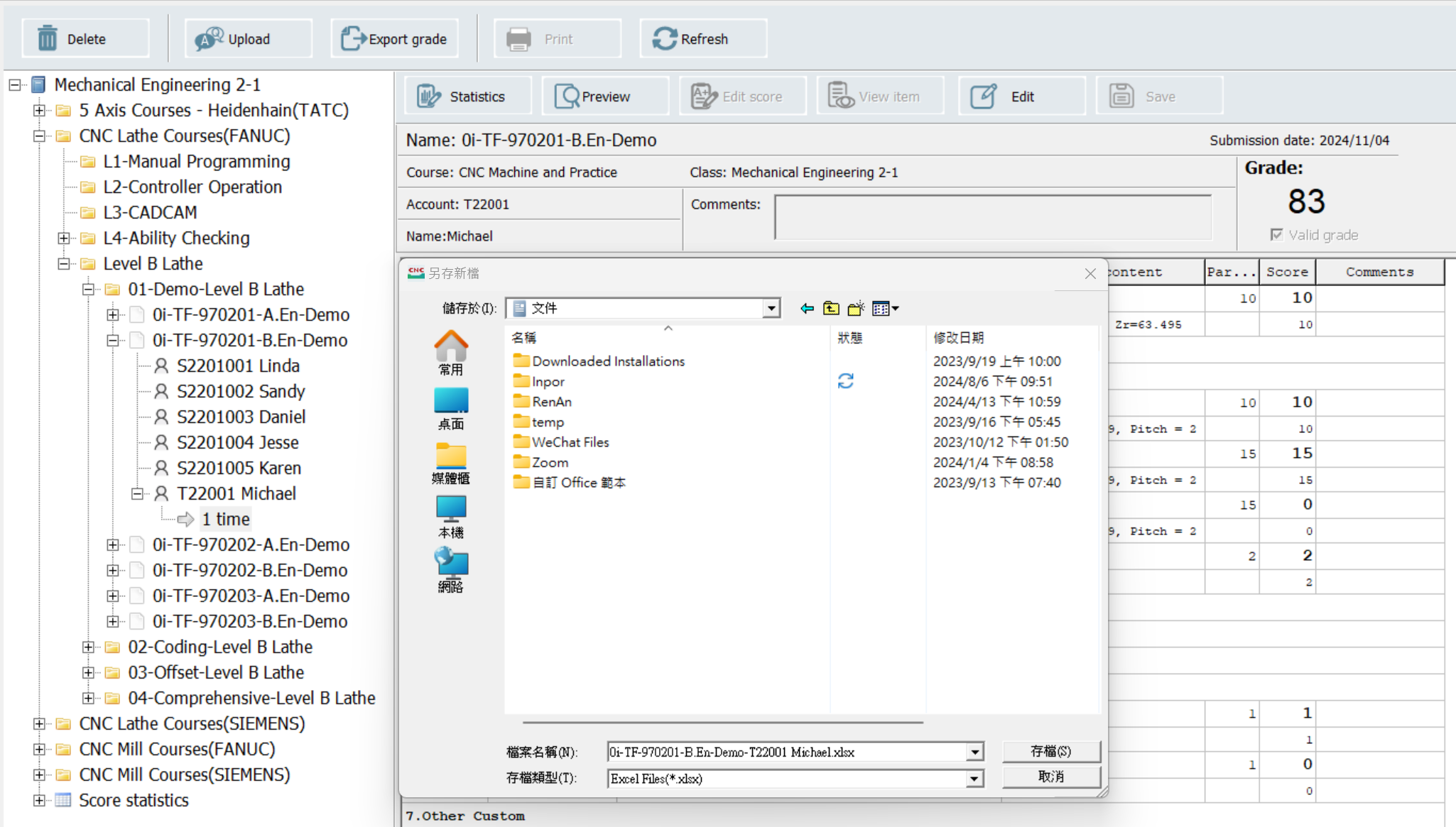

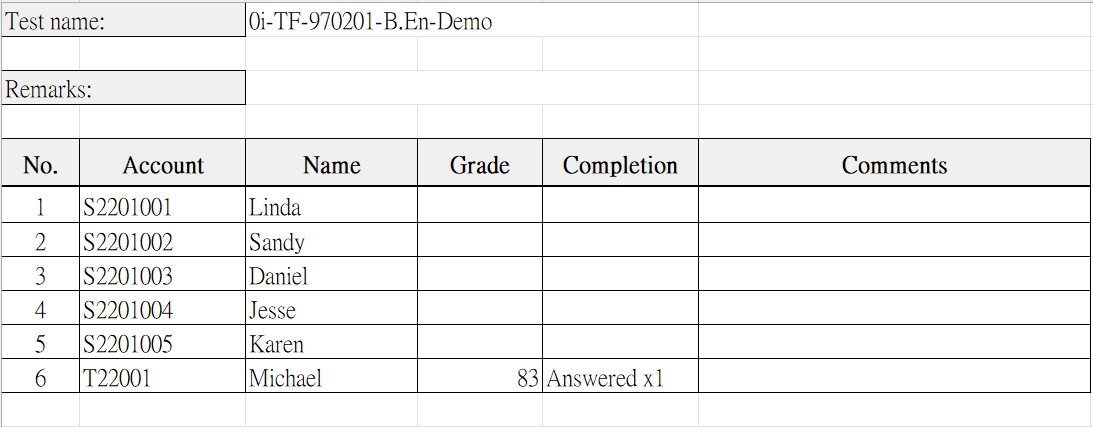

Evaluation > Student score

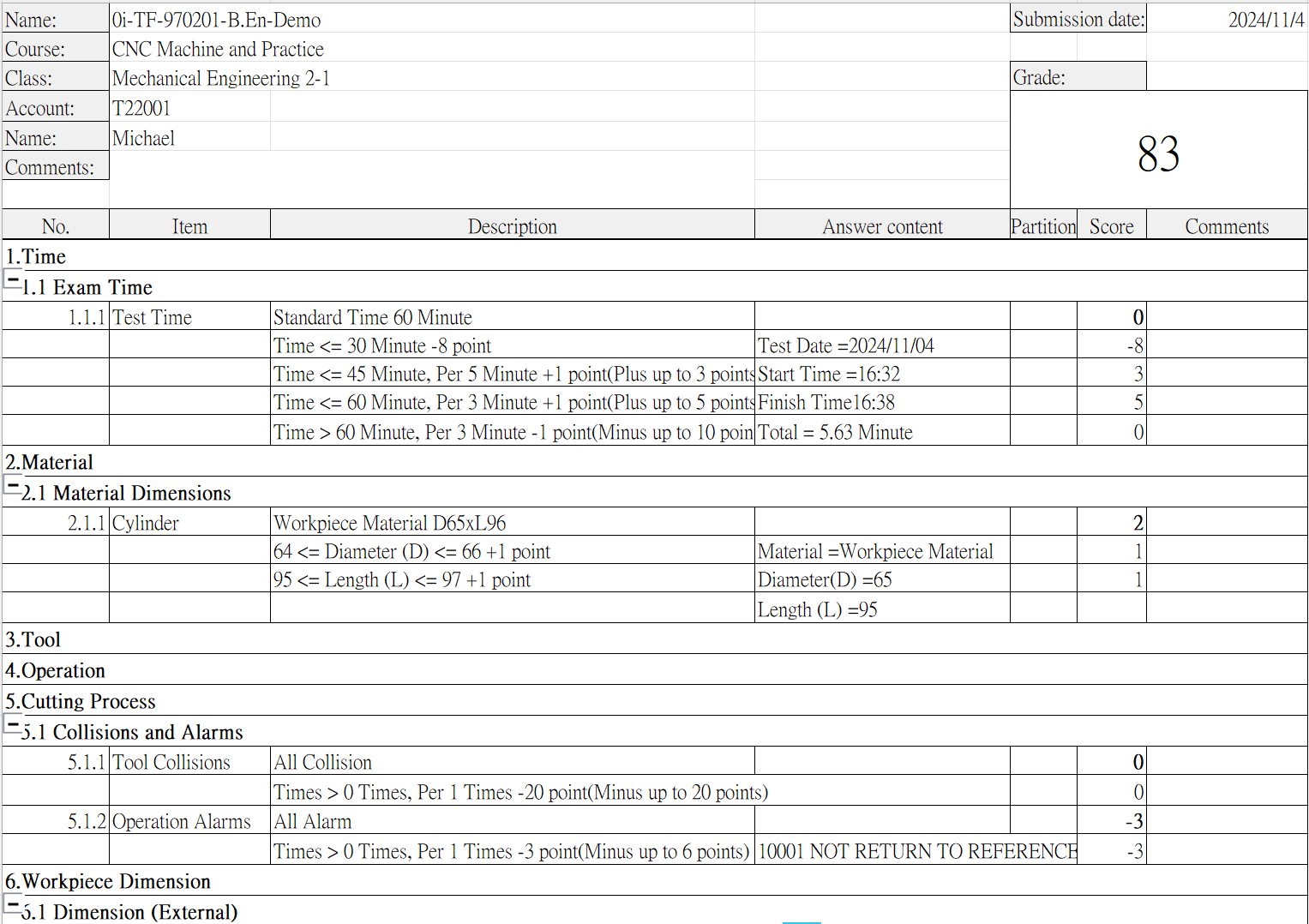

Evaluation sheet including standard items and score

- Time 2. Materials

- Cutting processing 6. Workpiece size

Export score sheet

Score table Excel format

Export the entire class score sheet

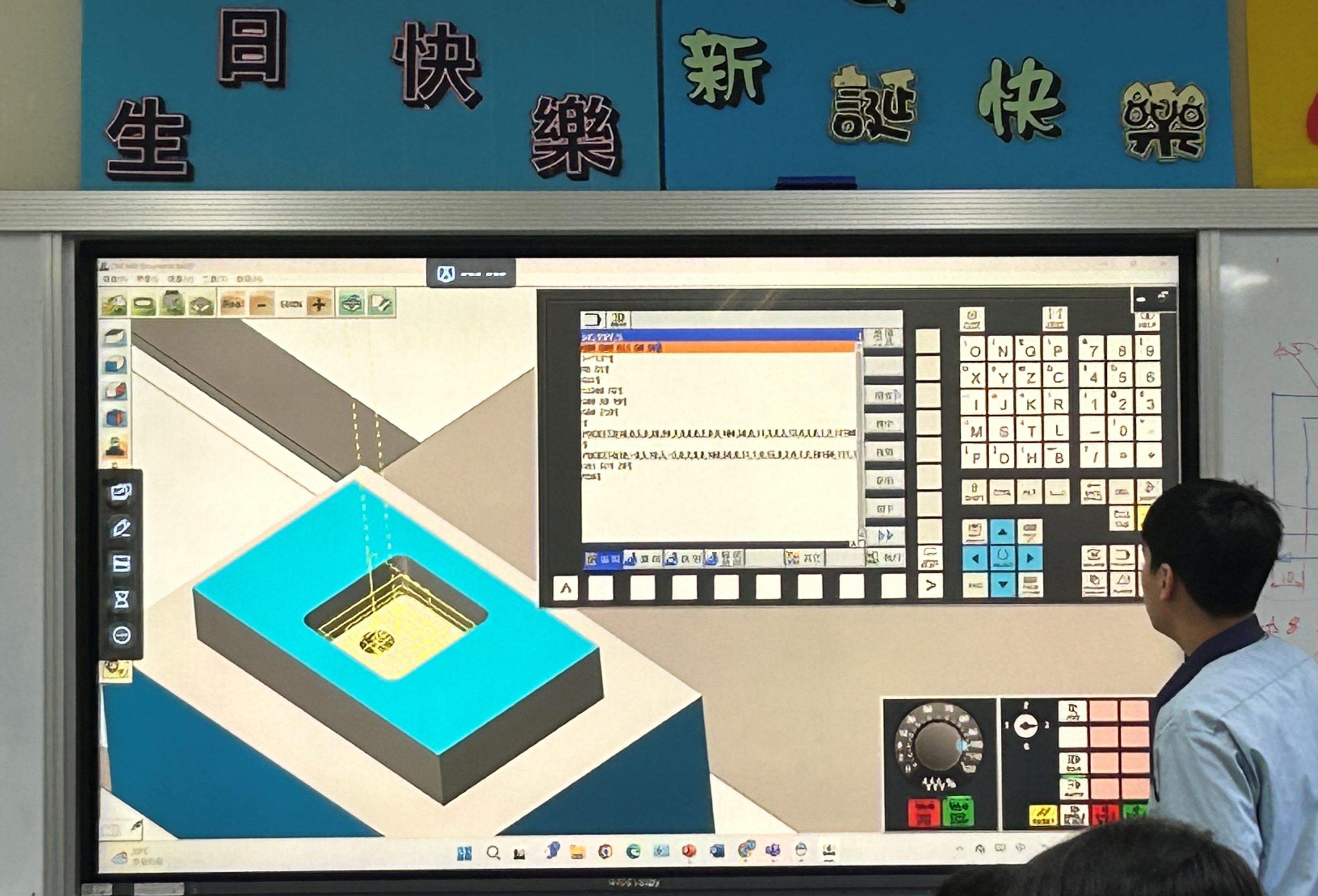

Use software teaching first to familiarize students with controller functions and machine operations

(The appropriate software system can be selected according to the controller model of the actual machine)

Students will be able to become more proficient when they actually use the computer, and develop a confident but cautious attitude in students.

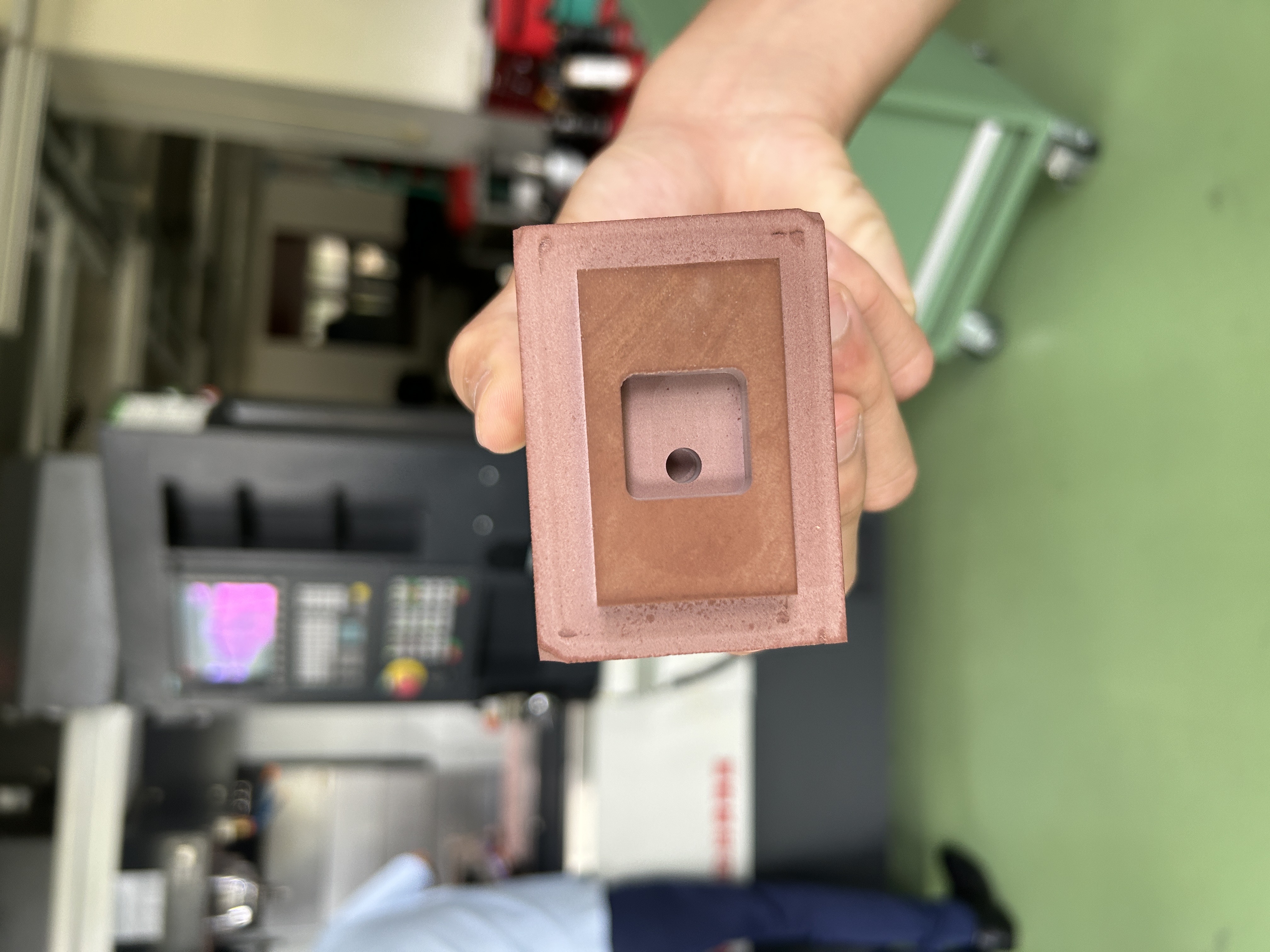

Actually processing the exact same workpiece is a great sense of achievement in learning!

文章區塊

產品區塊