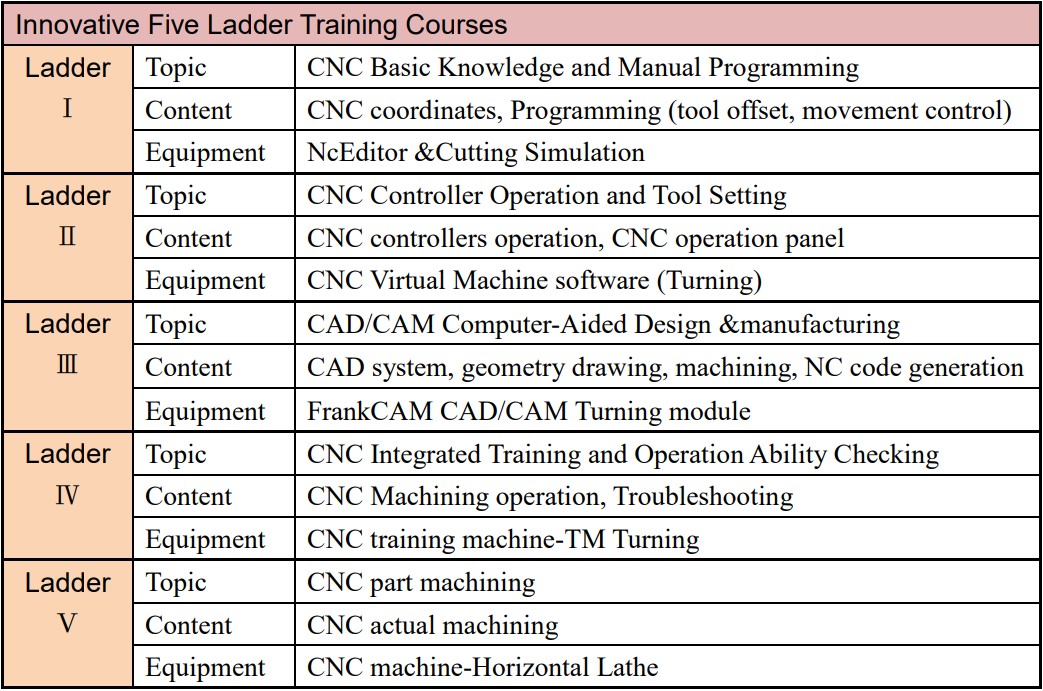

All

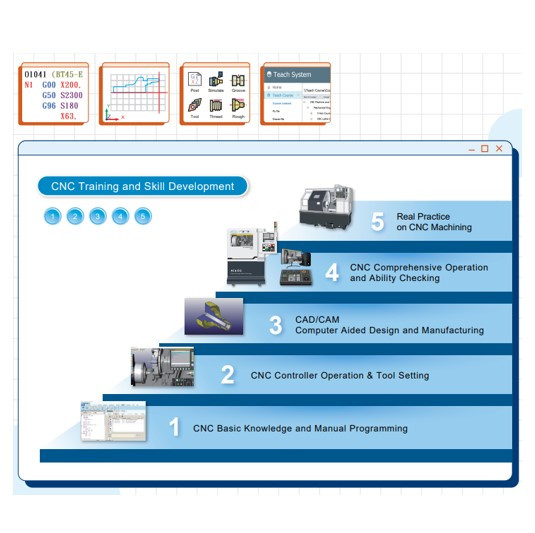

CNC Training and Skill Development

Five Ladder CNC Training Courses

Ladder 1 CNC Basic Knowledge and Manual Programming

Ladder 2 CNC Controller Operation

Ladder 3 CADCAM Software

Ladder 4 CNC Ability Checking

CNC machining software

replyBack

CNC Learning and Training Software L1-L3

Learning CNC step by step is like climbing a ladder

Including NcEditor, VM, FrankCAM

5 Ladder CNC Training Courses

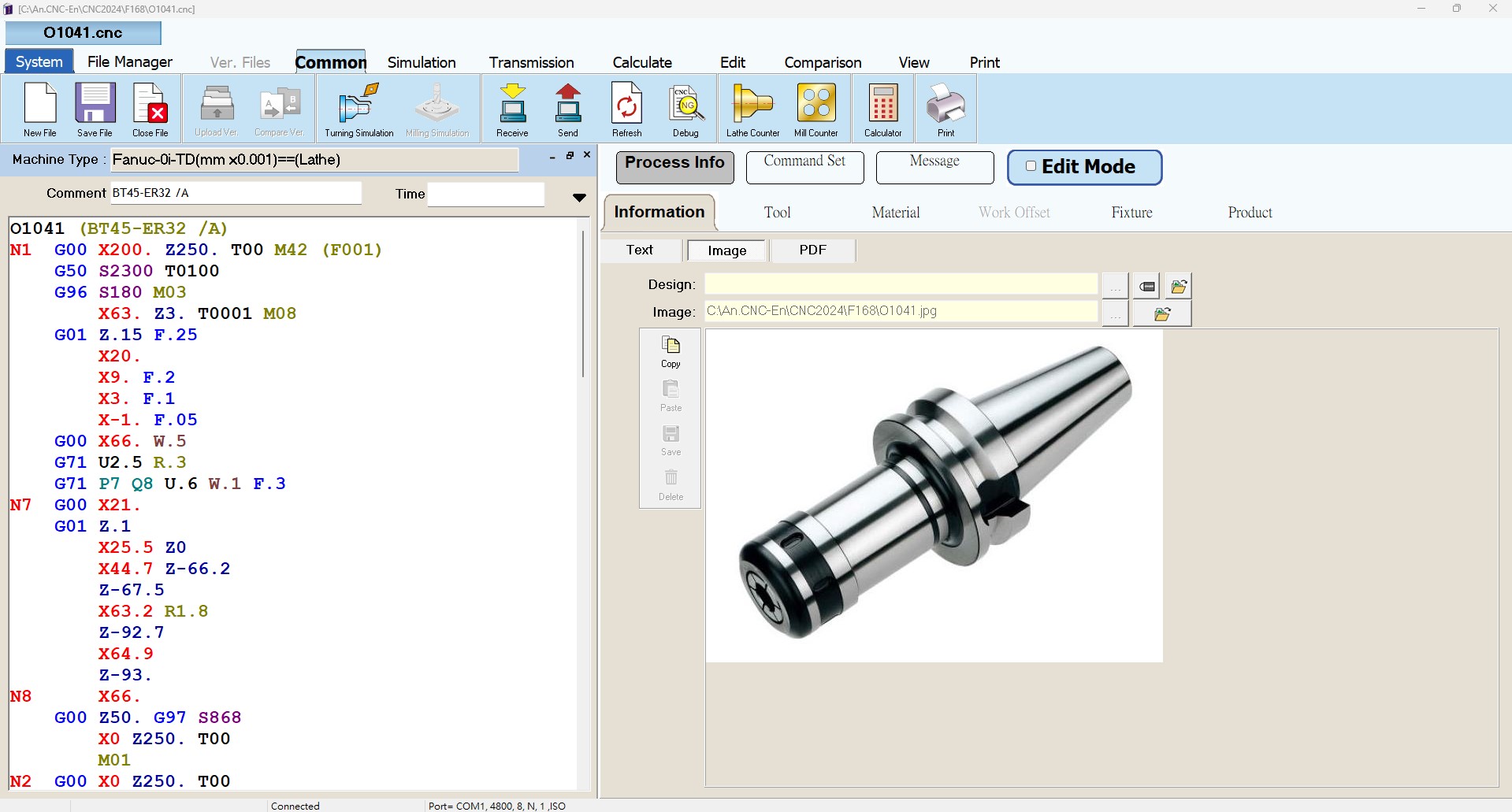

Ladder 1 : CNC Basic Knowledge and Manual Programming

By using NcEditor which equipped with clear colors setting and intelligent debug, students can easily find out the errors when they key in wrong commands and teachers save time to prepare for the next class. In addition, by using geometry expert to help students edit programs and to solve some problems on the calculations of tool nose radius compensation.

Furthermore, students simulate the cutting path to figure out the thorough process. Students cultivate their CNC solid knowledge by the basic programming to the concept of coordinates and cutting. This knowledge will tremendously influence on the accumulation of the machining experience.

Training Range, Purpose and Goal

1.2.1 Training Range

(1) CNC Basic Knowledge and Programming

(2) NcEditor Introduction

(3) Geometry Expert Introduction

(4) Cutting Path Simulation System

1.2.2 Training Purpose

(1) Understand the concept of numerical control

(2) Learning CNC Coordinates System

(3) Learning CNC Program Edit - Turning

(4) Learning NC Codes (G code, M code, S code, T code)

1.2.3 Training Goal

(1) Be familiar with CNC Coordinates System - Turning

(2) Be familiar with NC codes and program edit

(3) Be equipped with the ability of manual programming

(4) Knowing the theory and be equipped the ability of tool nose radius compensation

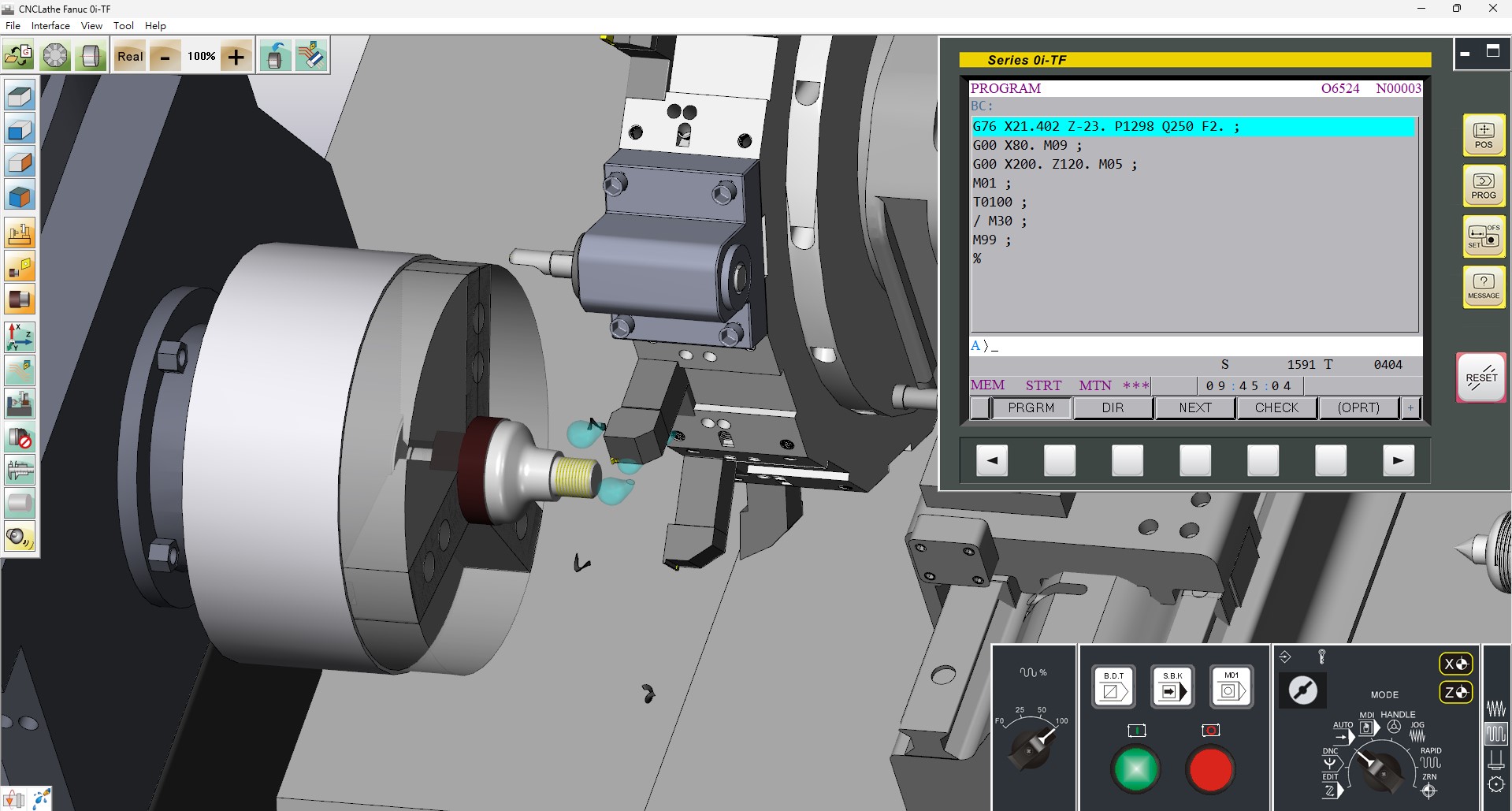

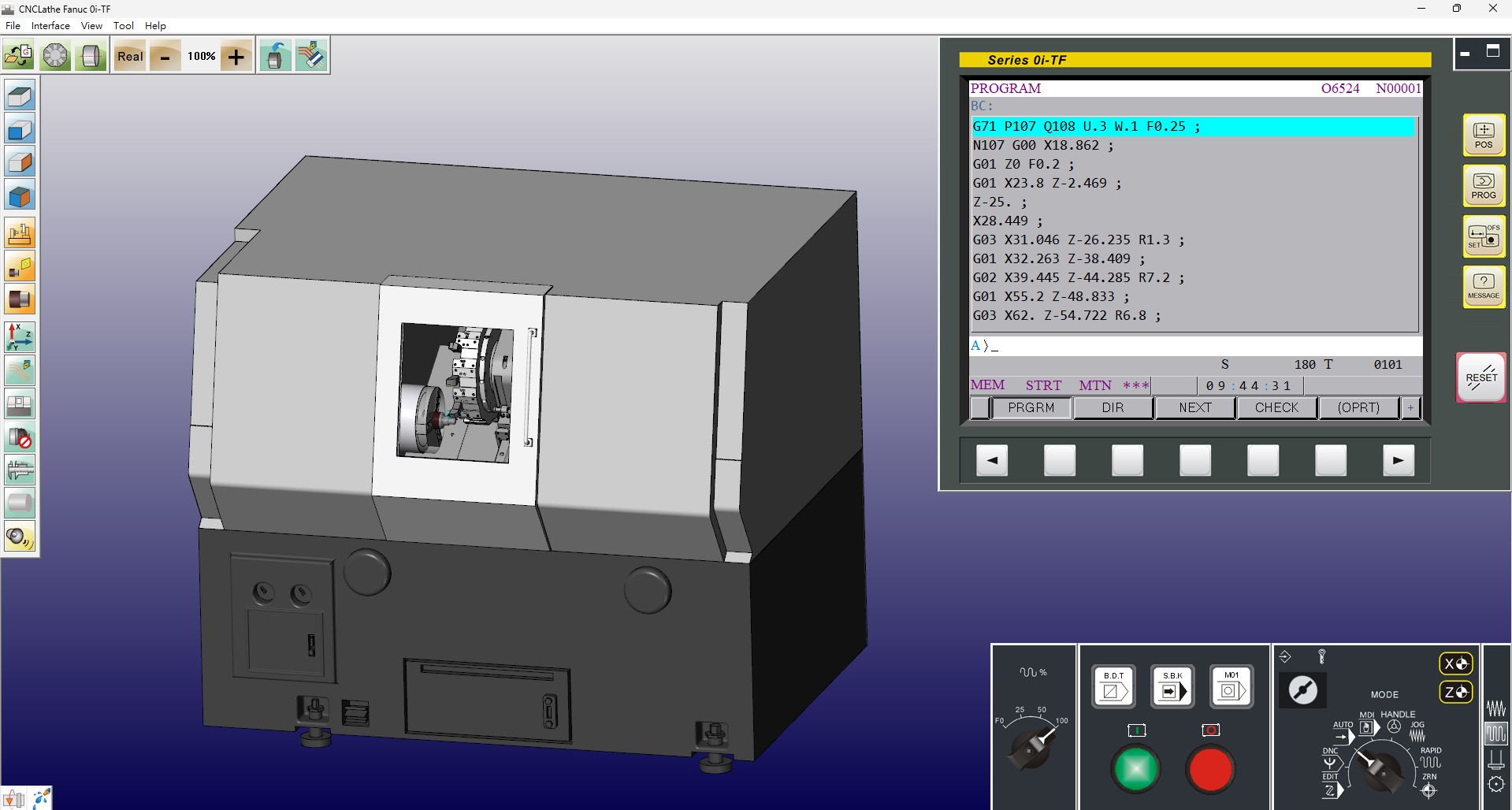

Ladder 2 : CNC Controller Operation and Tool Setting

Using PC to learn CNC controller will lower the barrier for beginners. CNC virtual machine simulation presents the whole CNC machine completely. To know the machine buttons precisely and realize the CNC machine operation by operating the controller interface. The virtual machine can run the program and presents the most realistic machine operation effects by combining machine bed and tools display.

CNC virtual machine uses the modular design machine operation panel to make learning much easier. The modular design only displays the buttons that are corresponding to the specific mode. For example: in auto mode, it only displays [Cycle Start], [Feed Hold] and [SBK] …etc. In handle mode, it only displays [Handwheel] and [Feedrate] switches…etc. By doing so, students can get familiar with the panels without teachers' reminders over and over again.

Training Range, Purpose and Goal

2.2.1 Training Range

(1) Fanuc-0i-TF Turning Controller

(2) CNC turning machine operation panel

(3) Suitable for beginner

2.2.2 Training Purpose

(1) Build a basic operation concept for machine

(2) Be familiar with controller and machine operation panel

(3) Let the learning resource accessible to every students and enable each to practice freely and independently

2.2.3 Training Goal

(1) Be equipped with the ability to return to the reference point and run the program automatically

(2) Be equipped with the ability to read and set the work coordinates

(3) Be equipped with the ability to use Rapid, JOG and Handle mode

(4) Be equipped with the ability of machining process and tool offset operation

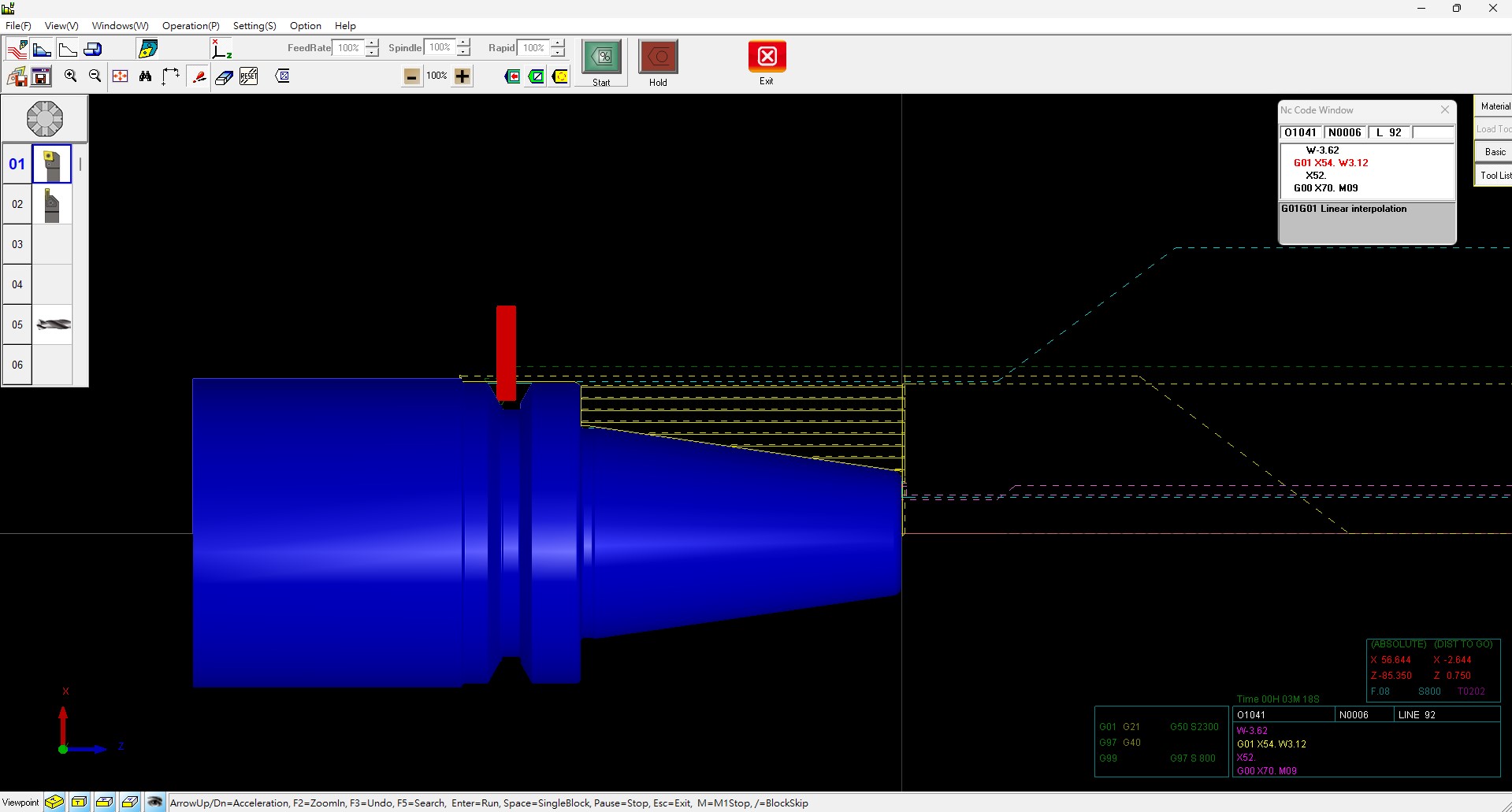

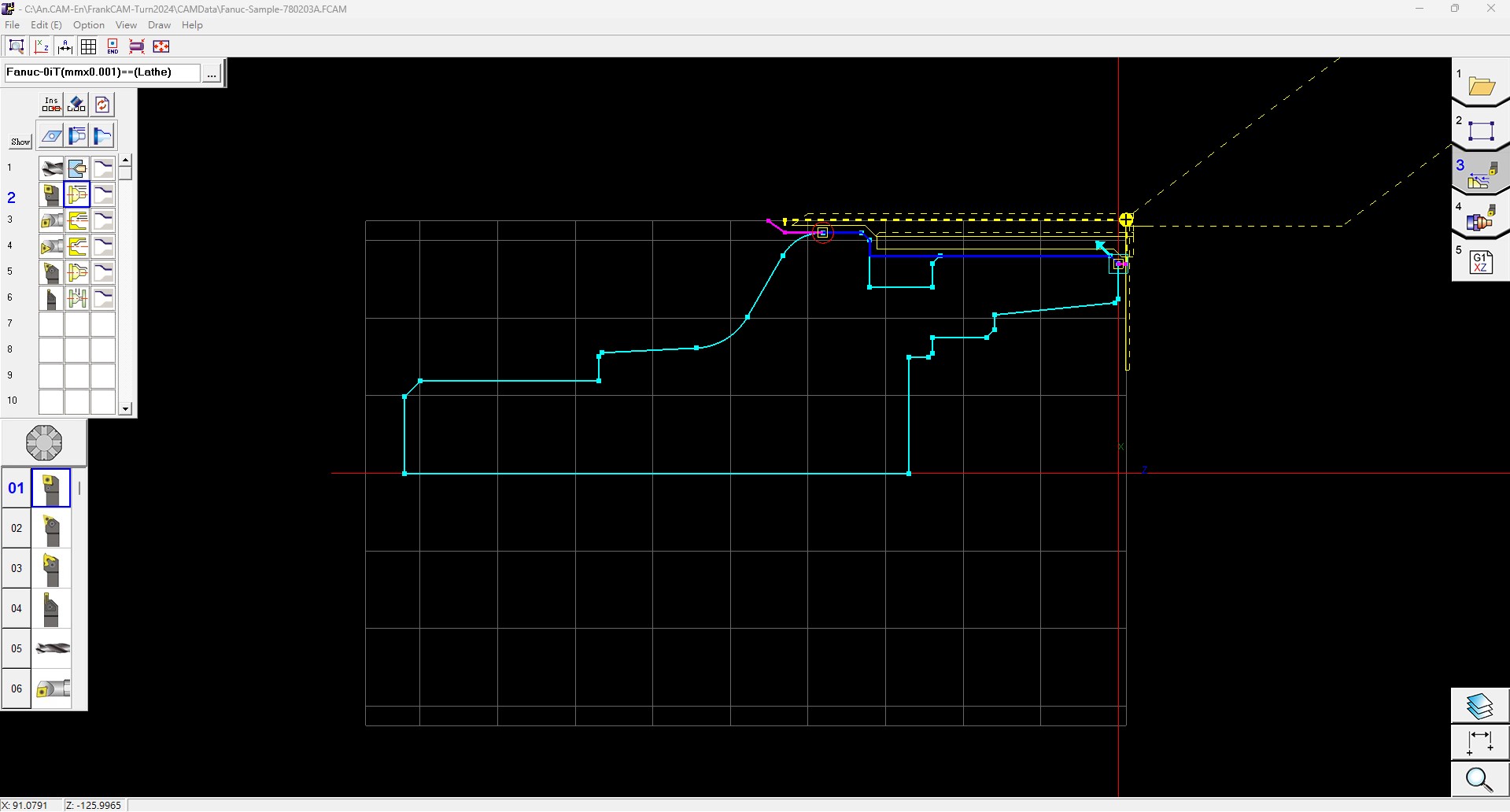

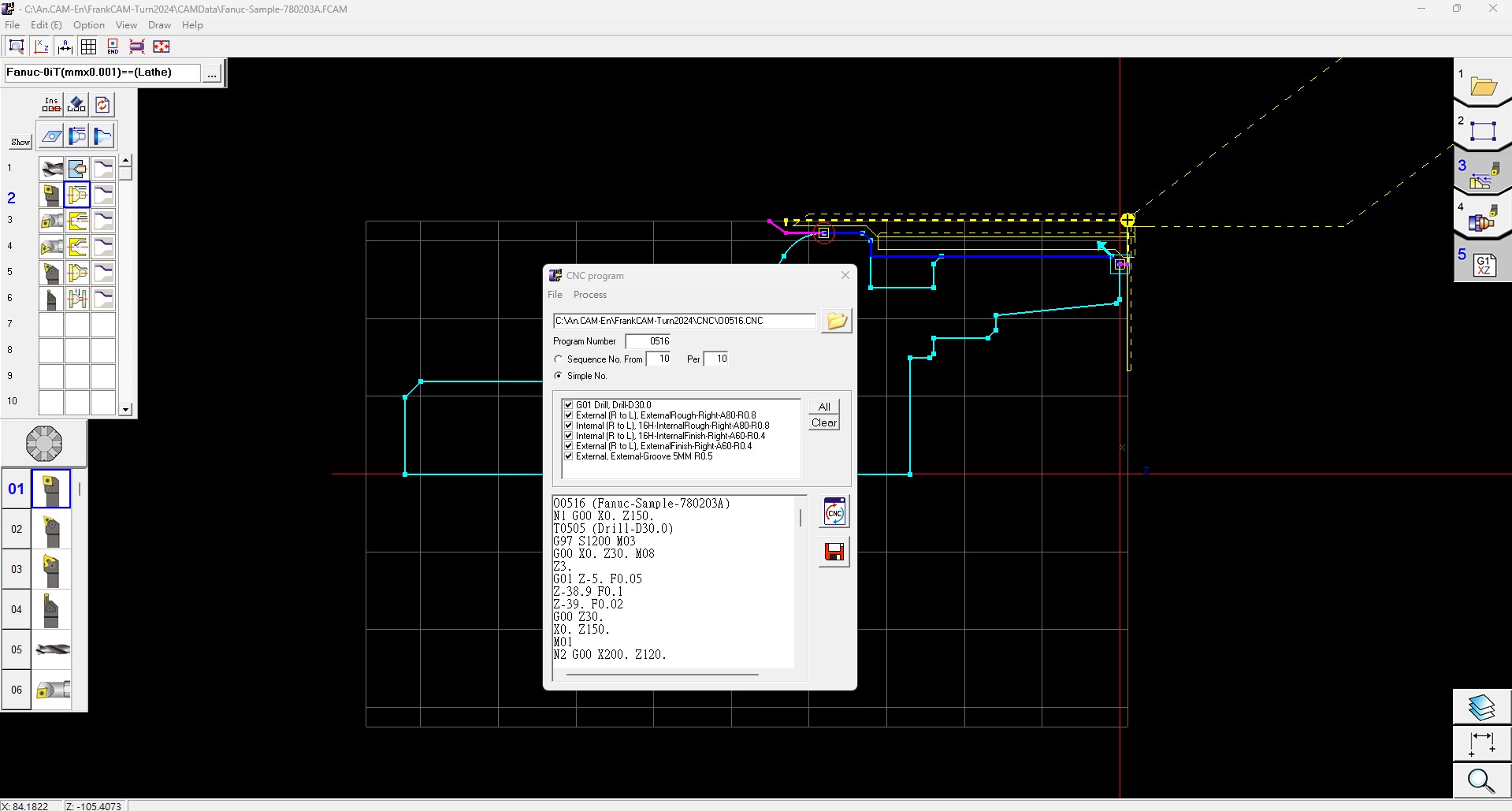

Ladder 3 : CAD/CAM Computer-Aided Design& Manufacturing

FrankCAM software uses guiding five - steps operations to make students easy to learn CADCAM software. RenAn CAD/CAM software not only save time but also make drawing, processing easier by clicking and selecting the contour automatically. FrankCAM software uses operational skill of computer-aided design & manufacturing to increase learning effectiveness. Learning drawing and auto-post CNC program generation can also break learning obstacle.

FrankCAM software is filled with practical knowledge and experience in machining area. It helps students understand the following: CAD drawing, complete cutting process setting. It use visualized graphic method to guide users setting external-rough, external-finish, slot, and thread process program quickly. It also generates CNC programs automatically, and executes 3D solid cutting simulation. With CAM Computer-Aided Design & manufacturing, students can establish correct basic concept.

Training Range, Purpose and Goal

3.2.1 Training Range

(1) FrankCAM Turning software

(2) CAD drawing and Turning machining edit

(3) 3D Simulation

(3) CNC program generation (post NC codes)

3.2.2 Training Purpose

(1) Use practical teaching in systematic and simple way, get in the habit of using assistant tool and operational skills

(2) Let beginner realize the workflow of CADCAM by user-friendly CADCAM

3.2.3 Training Goal

(1) Be equipped with the ability of CAD/CAM workflow

(2) Be equipped with the ability of basic workpiece turning operation

(3) Be equipped with the ability of drawing point, line, circle, chamfer and corner

(4) Be equipped with the ability of setting machining process, eg: external-rough, external-finish, tapping and thread

(5) Be equipped with the ability to check machining simulation and finished goods dimensions

5 Ladder CNC Training Courses Concept

Ladder 1 : CNC Basic Knowledge and Manual Programming

Basic introduction to CNC programs, manual programming

Ladder 2 : CNC Controller Operation and Tool Setting

CNC whole machine simulation, tool offset setting

Ladder 3 : CAD/CAM Computer-Aided Design& Manufacturing

User-friendly interface and easy to use CADCAM software

產品區塊